- Description

- Inquiry

Description

Functions and uses:

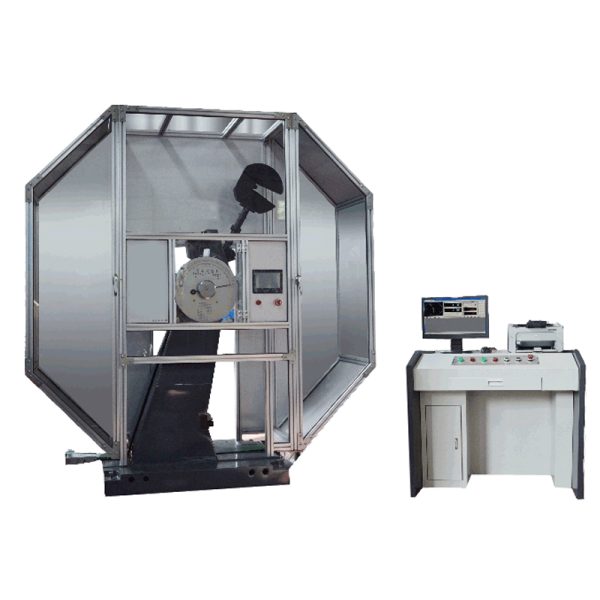

This series of impact testing machine is a high stiffness main engine, microcomputer control, automatic measurement record of the test machine, is the highest level of domestic pendulum impact testing machine.

This series of impact test machine is designed and manufactured according to ISO 148:1998, GB/T 3808-2010 test of pendulum impact test machine.Fully meet the domestic and international standards for impact testing of metallic materials.

This series of impact testing machine has passed the inspection and verification of various standard impact test samples at home and abroad, participated in and passed the international comparison test of impact test, obtained the European Union CE certification, passed the inspection certification of national testing machine quality supervision and inspection center, and passed the inspection of shandong institute of metrology.

This series of impact testing machine has powerful function, stable and reliable, accurate test and convenient operation.It is an ideal test equipment to test the impact resistance of metal materials under dynamic load and to judge the toughness and brittleness of materials.

This series of impact testing machine can be widely used in scientific research institutes, testing institutions, universities and colleges, aerospace, military industry, metallurgy, machinery manufacturing, pressure containers, ships, vehicles, Bridges, wind power and other fields.it precision of materials research, material analysis, materials development, material selection, process improvement and quality control.

Technical specification:

(1)Host and attached parameters:

| Item | JBW-750C |

| Maximum impact energy(J) | 750 |

| Effective range | 20%-80%FS |

| Prelift Angle of pendulum | 150° |

| The distance from the axis to the center of the blow | 750mm |

(2)Machine specification

| Item | JBW-750C | |

| Impact energy N | 535.8985 | |

| Moment of pendulum N·m | 401.9239 | |

| Impact speed | 5.24m/s | |

| Anvil block span | 40mm | |

| Corner radius of anvil holder | R1-1.5mm | |

| Slope Angle of anvil block | 11°±1° | |

| Impact blade Angle | 30°±1° | |

| Impact blade Curvature radius | 2mm Impact blade | 2mm-2.5mm |

| 8mm Impact blade | 8mm±0.05mm | |

| · 8mm Radius of Angle of impact blade and shoulder | 0.1mm-1mm | |

| · 8mm Impact edge width | 4mm ±0.05mm | |

| · Impact edge width | 10mm-18mm | |

| Impact edge thinkness | 16mm | |

| Meet sample specifications(mm) | 10×10×55mm,10×7.5×55mm, 10×5×55mm, 10×2.5×55mm | |

(3)The measured parameters:

| Item | JBW-750C |

| Angle measurement method | Photoelectric encoder |

| Angle accuracy | 0.06° |

| Digital display Angle resolution | 0.015° |

| Digital display power resolution | 0.12J |

| Minimum resolution of the dial | ≥1.25J |

| Energy display mode | Dial, LCD, microcomputer |

(4)Total machine specification:

| Item | JBW-750C | |

| Out size | Host | Install Grid guard 2220×900 ×2220(L×W×H)mm |

| Electric cabinet | 960×620×830(L×W×H)mm | |

| Weight | Host | About 1500Kg |

| Electric cabinet | About 100Kg | |

| Rate of power | 1.5kW | |

| Power | 3phase 5 wires,380V±10%,50Hz | |

| Use environment | No vibration, no dust;Room temperature(15-25℃);Humidity<70% | |

Test standard:

GB/T 2611-2007 《Test machine General technical requirements》

GB/T 3808-2010《Testing of pendulum impact testing machine》

GB/T 229-2007《Charpy pendulum impact test method for metallic materials》

JJG 145-2007《Pendulum impact testing machine》

ISO 148:1998《Metallic materials-Charpy pendulum impact test》

ASTM E23-07a《Standard Test Methods for Notched Bar Impact Testing of Metallic Materials》

GB/T 18658-2002《Charpy V notch standard sample for testing of pendulum impact testing machine》

JB/T 6147-2007 《Test machine packaging, packaging mark, storage and transportation technical requirements》