- وصف

- سؤال

وصف

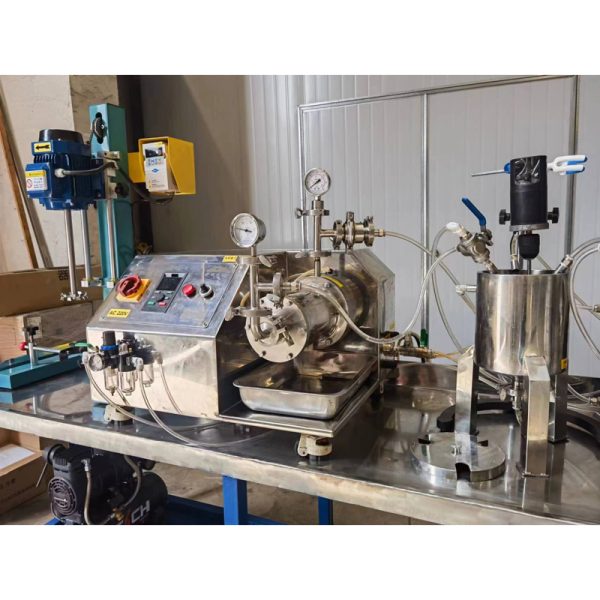

Nano grinder

مقدمة المنتج

In accordance with the design standards of European sand mills, the laboratory nano sand mill has large flow rate, good temperature control ability, high energy conversion rate, narrow particle size distribution range, especially the use of small grinding beads is optimized, flexible dispersion, efficient grinding.

Widely used in scientific research factories, مؤسسات البحث العلمي, الكليات والجامعات, enterprises and other wet grinding experiments and paint, حبر, الصباغ, color paste, functional ceramics, printing inkjet, tft/lcd color filter dispersion, lithium battery materials, heat sensitive paper, cmp, ceramic ink, nano powder, nano color paste and food additives and other fine chemical fields.

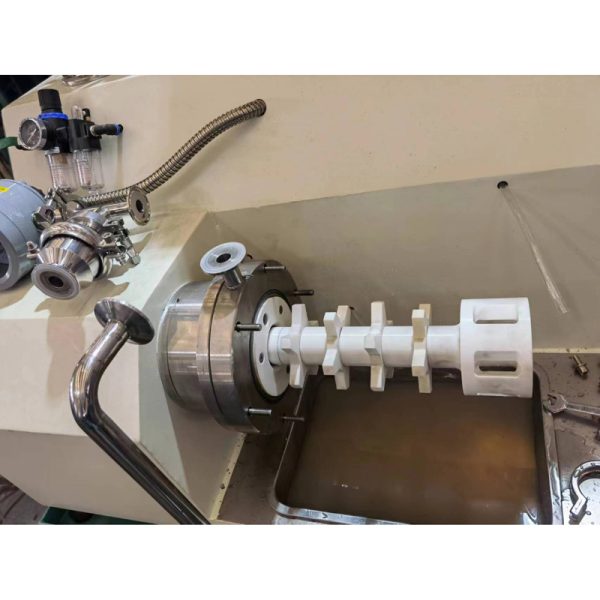

Rotor structure: disc type, rod pin, turbine

Grinding parts: سيراميك, البولي يوريثين, alloy steel

Nano grinder

orizontal sand mill working head structure type

The motor of the equipment drives the internal feeding device to rotate at high speed, forming negative pressure, and through the self-suction, the material placed in the upper tank is sucked and sent to the grinding chamber. The high filling rate of the grinding medium in the cavity is driven by the rotation of the force in all directions is not regular movement, the particles in the material receive the collision and friction of the grinding medium, while the screen makes the material and the grinding medium separate, the material constantly circulates from the tank to the grinding chamber to achieve the purpose of smaller particle size and narrower particle size range.

Nano grinder

| Technical parameters and configuration

| ملحوظة | ||

|

1 | Equipment grinding chamber | Capacity of grinding chamber: 1.8ل | |

| Inner cylinder material: silicon carbide | |||

| Zirconia rod pin | |||

| Cooling form: The cooling water is dissipated by the spiral channel of the grinding cylinder | |||

|

2 |

Mechanical seal | Double mechanical seal (Bergmann) | |

| Mechanical seal overall support material: الفولاذ المقاوم للصدأ (304) | |||

| Mechanical seal coolant delivery: natural cooling of circulating water | |||

| Mechanical seal cooling protection: monitored by water pressure sensor | |||

| Maximum feeding pressure of mechanical seal: 3كلغ | |||

| 3 | حجم فعال | 1ل | |

| 4 | Dispersion grinding mechanism | Number of zirconia rod pins: 24 قِطَع Rod pin base and turbine material: zirconia | |

| 5 | Material handling | Peristaltic pump | Flow adjustable |

| 6 | وضع الانفصال | Static screen discharge Clearance 0.15mm | مادة الفولاذ المقاوم للصدأ |

|

7 |

Principal axis | مادة: 3cr13 | |

| Tempering, heat treatment, طحن, | |||

| Manufacturing accuracy: according to GB6 standard execution | |||

| Bearing: NSK | |||

| 8 | Grinding medium | مادة: Pure zirconia (imported zirconia beads) مقاس: فاي-0.3مم The input amount is: 60%-80% |

|

| 9 | Equipment painting color | Exterior all stainless steel | |

| 10 | Feed pipe | Silicone hose | |

| 11 | ضغط | Maximum feed pressure: 2كلغ | |

| 12 | Electric appliance | 3KW motor 220V Speed 0-2800RPM, variable frequency speed regulation | |

| 13 | حجم الآلة: | 750*650*600 95كلغ | |