طريقة الاختبار وتحليل تطبيق مرونة الفيلم

في صناعة السينما, المرونة هي مؤشر الأداء الرئيسي, which reflects the performance of the film in the face of external stress and deformation. The flexibility of the film directly affects its performance and durability in different application scenarios. This article will explore in depth the importance of flexibility, its testing methods, and its wide application in industry.

Test method of film flexibility:

مرونة: The elasticity of the film determines whether it can be restored under the action of external forces. This relates to the resilience of the film under stretching and compression.

Plasticity: The plasticity of the film is whether there is permanent deformation under the action of external forces. This is essential for certain application scenarios, such as coatings that need to undergo deformation.

طريقة الاختبار وتحليل تطبيق مرونة الفيلم

التصاق: The adhesion of the film indicates whether it adheres tightly to the surface of the substrate and is not easy to peel or crack.

مقاومة التأثير: The ability of the film to resist rapid deformation, such as whether it is easy to break when an object strikes the surface of the coating.

Post-formability: The performance of the film in subsequent processing, such as whether it can maintain its flexibility and performance during the roll coating or molding process.

Flexibility test methods: In order to assess flexibility, a variety of test methods and instruments are widely used, the following are some common flexibility test methods:

Shaft rod tester: use steel shaft rods of different diameters, bend the coating template, and observe whether the coating is broken. The minimum available rod diameter indicates the flexibility of the film.

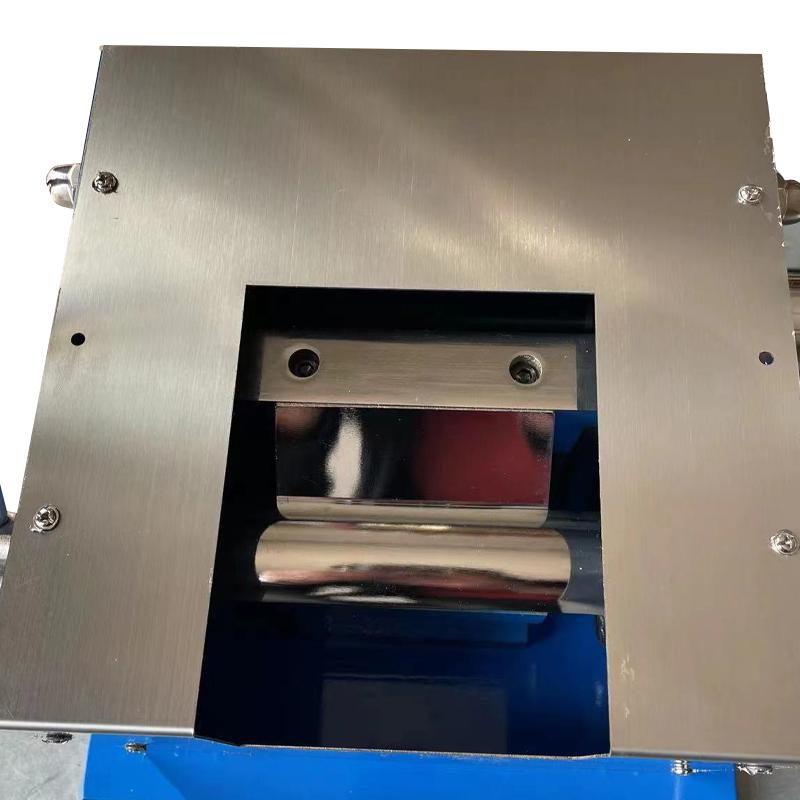

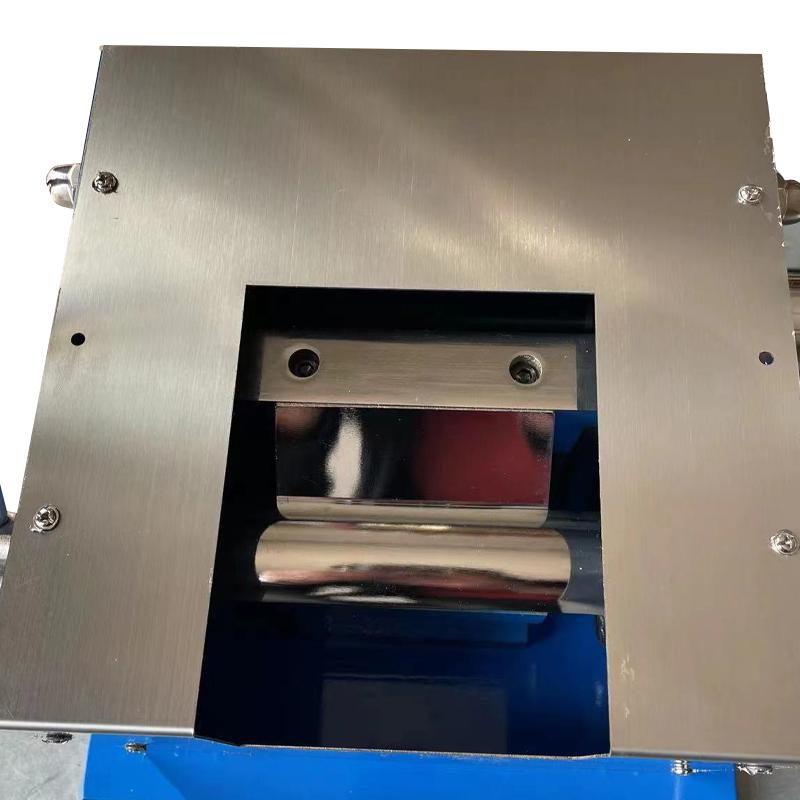

Cylindrical shaft bending tester: A thin test plate is bent using a cylindrical shaft to assess its flexibility by observing whether the film is cracked or peeled.

Conical deflection tester: Use a cone to bend the coating template and observe the minimum diameter that causes the film to break. It is suitable for the whole board test and reduces the influence of human factors.

Cup test machine: Use a spherical punch to push the back of the painted test plate to observe whether it causes the film to crack or peel. The minimum penetration depth indicates the flexibility of the film.

T-bending test: used for coil coatings, the test plate is folded to observe whether it is cracking, and then continuous testing is carried out, usually marked as 0T, 1ت, 2ت, إلخ., indicating the flexibility of the coating film.

طريقة الاختبار وتحليل تطبيق مرونة الفيلم

طريقة الاختبار وتحليل تطبيق مرونة الفيلم

Application of film flexibility

Film flexibility testing has a wide range of applications in the coatings industry:

رقابة جودة: Manufacturers can use flexibility testing to ensure that their coating products have the desired durability and adaptability in actual use.

Paint selection: Manufacturers can select paint types and formulations suitable for different applications based on the flexibility test results.

Post-formability assessment: Flexibility testing can be used to assess the performance of the film during subsequent processing, such as applications in the roll coating and molding industries.

Development and Improvement: By understanding the flexibility characteristics, the research and development team can improve the coating formulation to meet the changing application needs.

باختصار, flexibility is an indispensable performance indicator in the coating industry and is crucial to ensuring product quality and performance. By choosing the right test method, manufacturers can better understand the flexibility of their coating products and meet customer needs. The choice of the flexibility test method should be based on the specific situation and standard requirements to ensure the accuracy and comparability of the test results.