NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Oxidační stabilita mazacího oleje se týká schopnosti mazacího oleje odolávat procesu oxidačního zhoršování. Oxidation of lubricating oil in contact with air is inevitable. The longer the time, tím vyšší je teplota, the deeper the degree of oxidation. The result of oxidation will lead to increased acid value, increased viscosity, increased sediment, darker color, atd., shorten the service life of the oil. Oxidation stability is one of the important indexes to judge the aging property of lubricating oil and has important guiding significance for the service life of lubricating oil.

Standard number: NB/SH/T 0193-2022

Method A is to use an oil bath for testing, method B is to use a metal bath for testing. Method A is applicable to turbine oil and mineral insulating oil, Method B is applicable to turbine oil.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Method summary

Place the sample, water and copper catalyst coils in a covered glass sample holder in an oxygen bomb or magnetic cup fitted with a pressure gauge. The oxygen bomb is filled with oxygen at 620kPa pressure and placed in the specified constant temperature oil bath (turbine oil 150℃, mineral insulation oil 140℃) or the magnetic cup is placed in the metal bath at room temperature, filled with oxygen at 620kPa pressure, and then heated to 150℃, so that it rotates axially at a 30° Angle with the horizontal plane at a speed of 100 ot./min. The time required for the test to reach the specified pressure drop (min) is the oxidation stability of the sample.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Method application

1. Control the continuity of oxidation stability of different batches of turbine oil with the same composition and processing process;

2. Evaluate the remaining oxidation test life of turbine oil in use;

3. Check the continuity of oxidation stability of the mineral insulating oil produced.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Application standard case

1. Important indicators in GB/T 11120 “Turbine Oil” Standard

2. Technical requirements in NB/SH/T 0636 L-TSA Turbine Oil Change Index

3. Technical requirements in NB/SH/T 0137 “Anti-Ammonia Turbine Oil Change Index”

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Principle and summary of rotating oxygen bomb method

Test body: sample (50g±0.5g), voda (5ml), copper catalyst coil (electrolytic copper wire, diameter 1.63mm±0.01mm, čistota 99.9%) glass sample holder, oxygen bomb, oil bath or metal bath.

Operating conditions: Aeration operation at room temperature 25℃ (pressure up to 620 kPa±1.4 kPa) rotational speed 100r/min30° Angle axial rotation.

The result is reported: the time required to reach the specified pressure drop (175kPa from the maximum pressure drop) at the specified test temperature.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Major revisions

Major differences between NB/SH/T 0193-2022 and SH/T 0193-2008

(1) In the revised standard, a “turbine oil” is changed to “turbine oil”;

(2) In the application of methods in Chapter 5, 5.4 sample pretreatment was added to determine the percentage of RPVOT retention;

(3) In reagents and materials in Chapter 6, cleaning solution, chromic acid solution, light mineral oil and methanol are added, and potassium hydroxide alcohol solution is deleted;

(4) In Chapter 7 nástroje, added balance, measuring cylinder and timer, and method B test assembly;

(5) In Chapter 8 Vzorkování, requirements for sampling procedures and sample storage have been added;

(6) Metoda B(metal bath) is added;

(7) Added Chapter 11 Quality control inspection;

(8) In the report of Chapter 12, the result representation and the content of the result report are modified;

(9) In Chapter 13, Precision and Deviation, the provisions for repeatability and reproducibility are changed;

(10) Appendix A is amended as an informative appendix “Sample Pretreatment for Determination of percentage retention of RPVOT”;

(11) Modify Appendix B to the normative appendix “Rotating oxygen bomb oil bath test Equipment”, and add the content of calibration of temperature control system and pressure measurement system;

(12) Added normative Appendix C “Rotating oxygen bomb metal bath test equipment”;

(13) Added normative Appendix D “Thermometer Technical Specifications”.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Significant revisions

● Sampling:

SH/T 0193-2008: Samples may be obtained from oil tanks, drums, small containers or operating devices, sampling methods and equipment are specified in GB/T 4756.

NB/SH/T 0193-2022: Sample preparation and transfer to other containers shall be in accordance with GB/T 4756. Samples should be stored away from light and in dark colored bottles. Samples can be obtained from oil tanks, drums, small containers or operating devices, and since the results obtained by this method are easily affected by trace impurities, contamination in sampling and subsequent processes should be avoided, especially in the case of used lubricating oil.

● Revision of traditional methods

● Added Method B

Metoda A: Silicone oil bath (oil bath depth of at least 230mm, filled with 30L silicone oil)

Oxygenate at room temperature, and then put the projectile body into the oil bath that has reached the test temperature.

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Metoda B: Metal bath

Before the metal bath is heated, the projectile body is oxygenated in it and then reheated to the test temperature.

● Applicability of method B

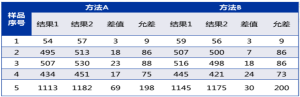

Five samples were obtained by adding different proportions of additives to the base oil, and the same sample was tested using standardized instruments (oil bath equipment in method A) and metal bath equipment used in new method B. The results are as follows:

● Calibration work

Pressure measuring system

Frekvence: Every 100 trials or up to 3 months

Appliance: Calibrated pressure gauge with an accuracy of 2.5% of the total range

Calibration point: 620kPa±0.69kPa

Systém regulace teploty

Frekvence: Calibration every six months

Liquid bath: Certified thermometer, accurate to 0.1℃

Metal bath: Certified thermometer, accurate to 0.1℃, water sample

● Determine the percentage of retaining power of a rotating oxygen bomb (RPVOT)

Method Application: L-TGSB and L-TGSE fuel/steam turbine oils require improvement of rotary oxygen bomb index

Method summary: The sample was placed at 121℃ and ventilated with nitrogen for 48h. At the end of the experiment, RPVOT was determined on the oil samples

NB/SH/T 0193-2022 (Stanovení oxidační stability mazacího oleje metodou rotující kyslíkové bomby) standardní výklad

Výsledek ukazuje:

RPVOT% value of new oil = (RPVOTf/RPVOTi) ×100%, where:

RPVOTi — RPVOT results of unpretreated samples (min)

RPVOTf — RPVOT results of pre-treated samples (min)