ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

panimula

ISO (International Organization para sa Standardisasyon) ay isang pandaigdigang alyansa ng mga pambansang pamantayan katawan (Mga katawan ng miyembro ng ISO). Ang pagbuo ng mga internasyonal na pamantayan ay karaniwang isinasagawa sa pamamagitan ng ISO teknikal na komite. Ang bawat institusyon ng miyembro na interesado sa isang paksa kung saan itinatag ang isang teknikal na komite ay may karapatang kumatawan sa komiteng iyon. Ang mga internasyonal na organisasyon ng pamahalaan at di pamahalaan na nakikipag ugnayan sa ISO ay kasangkot din sa gawaing ito. ISO ay gumagana nang malapit sa International Electrotechnical Commission (IEC) sa lahat ng bagay ng electrical standardization.

International pamantayan ay drafted alinsunod sa mga patakaran na ibinigay sa Bahagi 3 ng Direktiba ng ISO / IEC.

Ang draft international standard na pinagtibay ng Technical Committee ay ipapakalat sa mga miyembro ng mga katawan para sa pagboto. Ang paglalathala bilang isang internasyonal na pamantayan ay nangangailangan ng pag apruba ng hindi bababa sa 75% ng mga miyembrong institusyon.

Please note that some elements of this part of ISO 6603 May be the subject of a patent right. Ang ISO ay hindi mananagot para sa pagtukoy ng anuman o lahat ng naturang patente.

The international standard ISO 6603-1 was developed by the Technical Committee ISO/TC61, Mga plastik, Subcommittee SC 2, Mechanical Properties.

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

Ang ikalawang edisyon ay kinakansela at pinalitan ang teknikal na binagong unang edisyon (ISO 6603-1:1985).

ISO 6603 binubuo ng mga sumusunod na bahagi, under the general heading Plastics – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik:

– Bahagi 1: Pagsusuri ng di instrumental na epekto

– Bahagi 2: Instrumented impact testing

Appendix A of this part of ISO 6603 is for information purposes only.

1 Saklaw

This standard specifies a method for determining, under specified conditions, the puncture impact properties of rigid plastics in the form of flat specimens, such as disks or squares. The sample can be molded directly, cut from the sheet or removed from the finished product. Different types of samples and test conditions are defined.

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

These drop dart methods are used to study the behavior of plastic films or molds under the impact of a firing pin perpendicular to the specimen plane.

Ang bahaging ito ng ISO 6603 can be used if it is sufficient to characterize the impact behavior of plastics by an impact failure energy threshold based on many samples. If a force-deflection or force-time plot recorded at a nominal constant firing pin speed is necessary to characterize impact behavior in detail, ISO 6603-2 is used.

These test methods are suitable for specimens with thicknesses between 1 mm and 4 mm.

Note For thicknesses less than 1 mm, ISO 7765 ay inirerekomenda. If the equipment is suitable, it is possible to test thicknesses greater than 4 mm, but this test falls outside the scope of ISO 6603-1 at ISO 6603-2.

These methods are suitable for the following types of materials:

Rigid thermoplastic molding and extrusion materials, including filled, unfilled and reinforced compounds and sheets;

– Rigid thermosetting molding and extrusion materials, including filling and reinforcing compounds, sheets and laminates;

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

Fiber-reinforced thermoset and thermoplastic composites, including unidirectional or non-unidirectional reinforcement materials, such as MATS, woven fabrics, woven roving, cut strands, combined and mixed reinforcement materials, roving, milled fibers and sheets made from pre-impregnated materials (prepregs).

These methods are also applicable to samples molded or machined from finished products, laminates and extruded or cast plates.

The test results are comparable only when the preparation conditions, size and surface of the sample and the test conditions are the same. Sa partikular na, the results determined on specimens of different thicknesses cannot be compared with each other (see Appendix E: – to ISO 6603-2). A comprehensive assessment of the impact stress response requires measurement of the impact velocity and temperature of different material variables, such as crystallinity and moisture content.

The impact behavior of the finished product cannot be predicted directly from this test, but samples can be taken from the finished product (see above) for testing by these methods.

Test data developed through these methods should not be used in design calculations. Gayunpaman, information on the typical behaviour of the material can be obtained by testing at different temperatures and impact velocities (see Annex D of ISO 6603-2: -), varying thickness (see Annex E of ISO 6603-2: -) and testing samples prepared under different conditions.

Ang bahaging ito ng ISO 6603 describes two statistical test methods:

– Paraan A: Staircase Method (Individual) (preferred)

In this method, a uniform energy increment is used during the test. After testing each sample, the energy is reduced or increased by uniform increments, depending on the observations (pass or fail) of the previous test.

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

– Paraan B: Group method (Opsyonal na)

In this method, a continuous group of at least ten samples is tested. The impact failure energy is calculated statistically.

2 Mga reperensyang normatibo

The following normative documents contain provisions that, by reference herein, constitute the provisions of this part of ISO 6603. Para sa mga petsang sanggunian, any subsequent revisions or amendments to these publications will not apply. Gayunpaman, Parties to agreements based on this part of ISO 6603 are encouraged to investigate the possibility of applying new versions of the following normative documents. Para sa mga walang petsang sanggunian, a new version of the standard-setting document referred to applies. ISO and IEC members maintain a register of currently valid international standards.

ISO 291:1997, Mga plastik. Adjust and test the standard atmosphere.

ISO 293:1986, Mga plastik. Compression forming sample of thermoplastic material.

ISO 294-3:1996, Mga plastik. Injection molding of thermoplastic material samples. Bahagi 3: Small board.

ISO 295:1991, Mga plastik. Compression molding of thermosetting material samples.

ISO 1268:19741), Mga plastik – Preparation of glass fiber reinforced, resin bonded, low pressure laminates or panels for test purposes.

ISO 2818:1994, Mga plastik. The sample was prepared by machining.

ISO 7765-1:1988, plastic films and sheets. The impact resistance was determined by the free falling dart method. Bahagi 1: Staircase method.

ISO 7765-2:1994, plastic films and sheets. The impact resistance was determined by the free fall dart method. Bahagi 2: Instrumental puncture test.

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

3 Mga tuntunin at kahulugan

For the purposes of this part of ISO 6603, Ang mga sumusunod na termino at kahulugan ay nalalapat:

3.1 Pangkalahatang ideya

3.1.1 Failure

Any visible breakage of the specimen surface

3.2 Failure standard terms

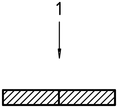

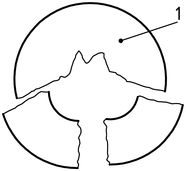

3.2.1 Crack

Any cracks that are visible to the naked eye and cannot penetrate the entire thickness of the material

Tingnan sa: Larawan 1

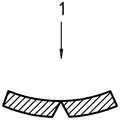

3.2.2 Broken

Any cracks throughout the entire thickness of the material

Tingnan sa: Larawan 2

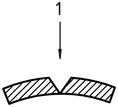

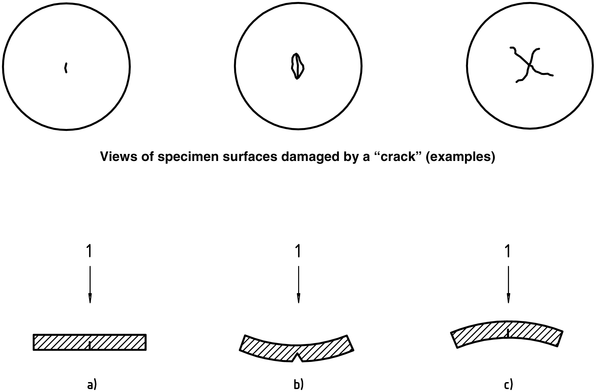

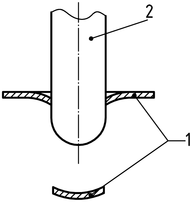

3.2.3 Penetration

Failure of the firing pin to penetrate the entire thickness of the specimen

Tingnan sa: Larawan 3 b)

3.2.4 Grinding

Break the sample into two or more pieces

Tingnan sa: Larawan 3 a)

3.3 Impact failure items

3.3.150 % impact failure energy E50

The energy that causes 50% of the sample to fail, as defined in 3.1.1

3.3.250 % impact failure mass M50

The mass that causes 50% of the sample to fail at a given fall height, as defined in 3.1.1

3.3.350 % impact failure mass H50

50% impact failure height H50 uses the height at which a given falling mass causes 50% sample failure, as defined in 3.1.1

Larawan 1 – Specimen sections damaged by “cracks” [b) and c) after bending by hand

| 1 | Impact direction |

ISO 6603-1-2000 “Mga plastik – Pagpapasiya ng puncture epekto pag uugali ng matigas na plastik – Bahagi 1: Pagsusuri ng di instrumental na epekto”

Larawan 2 – Slices passed through the specimen are damaged by “breakage” [b) and c) after bending by hand

| a)

| b)

| c)

|

| 1 | Impact Direction |

Larawan 3 – Examples of “broken” failures [a) at “penetrated” [b)

a)

b)

| 1 | Specimen |

| 2 | Darts with hemispherical heads |

Ang standard information section lamang ang pampubliko. Upang makita ang buong nilalaman, kailangan mong bilhin ang pamantayan sa pamamagitan ng mga opisyal na channel.