- Paglalarawan

- Pagtatanong

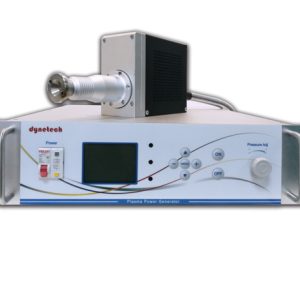

Paglalarawan

Parameter ng produkto

Panimula sa mababang temperatura plasma ibabaw paggamot teknolohiya

The energy of particles in low temperature plasma is generally about several to ten electron volts, na kung saan ay mas malaki kaysa sa bond enerhiya ng polimer materyales (several to ten electron volts), and it can completely break the chemical bonds of organic macromolecules and form new bonds. Gayunpaman, it is much lower than high-energy radioactive rays and only involves the surface of the material without affecting the properties of the matrix. Sa mababang temperatura plasma sa di termodinamikong ekwilibriyo estado, ang mga elektron ay may mataas na enerhiya, na maaaring masira ang mga bono ng kemikal ng mga molecule sa ibabaw ng mga materyales at mapabuti ang reaktibiti ng kemikal ng mga particle (mas malaki pa sa hot plasma), habang ang temperatura ng neutral na mga particle ay malapit sa temperatura ng kuwarto. Ang mga pakinabang na ito ay nagbibigay ng angkop na mga kondisyon para sa pagbabagong ibabaw ng mga polymers na sensitibo sa init. Sa pamamagitan ng mababang temperatura plasma ibabaw paggamot, ang iba't ibang mga pisikal at kemikal na pagbabago ay nangyayari sa ibabaw ng materyal, or produce turbidity-etching and rough or form a dense cross-linked layer, or introduce polar groups containing oxygen, upang ang hydrophilicity, cohesiveness, Chromability, biocompatibility at mga katangian ng kuryente ay pinabuting. When the material surface is treated under the appropriate technological conditions, the surface morphology of the material changes significantly. A variety of oxygen-containing groups are introduced to make the surface change from non-polar, difficult viscosity to a certain polarity, easy viscosity and hydrophilicity, which is conducive to bonding coating and printing. The air between the two electrodes generates gas glow discharge by applying AC high frequency and high voltage to the two electrodes. The electrons constantly collide with the gas molecules and produce a large number of new electrons. When these electrons reach the anode, they gather on the surface of the medium and modify the surface

Product processing time

Aviation industry

Plasma cleaning applications

With the development of the aviation industry, manufacturers are looking for products with longer life spans, more reliable quality and lower costs. In the past, the coating and stripping strips on aircraft were made of aluminum alloy, but now, these parts are mainly made of carbon fiber reinforced plastics. Plasmas play a big role in this. Carbon fiber reinforced plastic surface stability is better, so that the bonding and spraying process presented a more perfect state

Metal industry

Whether it is from the metal ornaments in our clothes or the metal tables and chairs used in our homes, the surface may be treated by plasma. Nowadays, people have higher and higher taste for the design of products. Manufacturers in order to meet the needs of consumers will produce a variety of beautiful and durable metal products to attract the market, it can be said that plasma surface treatment of materials has infiltrated into our lives, in the past 30 mga taon, low temperature plasma is widely used to change the mechanical properties of the surface of metal materials, plasma surface treatment of metal is :

1. The friction and corrosion resistance of iron and steel alloys were improved by ion beam nitriding

Metal industry

2. Ions injected into the metal surface can form metal solid solution and sediment, so it can improve the hardness and wear of metal materials

Industriya ng medisina

Medical materials refer to inanimate materials used in contact with biological tissues to form functions. They are very good auxiliary materials in medical treatment, including polymer materials, metals, Keramika, glass or composite of various materials, atbp., which are widely used in artificial organs, surgical repair, dental materials, cladding materials, orthopedic devices and medicine. Functional and mechanical properties, these materials are very good, but good biocompatibility is also quite critical, using plasma surface modification method can make them good compatibility, plasma only on the surface of a thin layer of treatment, does not change the performance of the material, and sterilization effect. So plasma surface treatment is becoming more and more widely used in medical materials.

Industriya ng appliance sa sambahayan

The surface coating, spraying and bonding process of daily necessities and household appliances, plasma pretreatment to improve the quality of bonding and coating

Industriya ng plastik

plastik na plastik, goma na, metal and other pretreatment before bonding, mapabuti ang pagdikit sa ibabaw, mobile phones, mga computer, toys and other plastic shell spray pretreatment, mapabuti ang pagdikit sa ibabaw

Industriya ng packaging

In the field of printing and packaging applications, perhaps in the previous plasma surface treatment is not much known to the public, in fact, we began to use the corona discharge, flame treatment surface modification method, which is the most common form of discharge in the ion – mass barrier discharge (DBD) but now low temperature plasma processor has been widely used in the packaging industry, Change the printability of the packaging surface and the adhesion of the composite surface, plasma processing function for UV, patong na patong, glazing, polymer and other materials surface treatment; Propesyonal na mapabuti ang pinahiran papel, glazed paper polishing, baraha ng ginto at pilak, aluminum coated paper UV, OPP, PP, Alagang Hayop at iba pang mga kahon ng kulay, kahon ng kulay ibabaw paste box fastness; Eliminate all kinds of packaging box opening problem. Improve work efficiency, reduce grinding pollution, eliminate paper powder pollution of box paste machine, save consumables, save glue cost.

Katumpakan baso

Photoelectric glass and electronic industry applications

9. Lahat ng uri ng paglilinis ng ibabaw ng salamin, mapabuti ang glass ibabaw hydrophilicity, optimize ang glass coating, paglilimbag, bonding at pag spray ng teknolohiya;

@ Flexible and non-flexible printed circuit board contact cleaning, LED floresan lampara “makipag-ugnay sa” paglilinis at pagbutihin ang ibabaw malagkit firmness; Electronic components PCB cleaning, IC paglilinis ng ibabaw, pagpapagana ng pagpapagana ng pagbubuklod, atbp.; @LCD LCD screen terminal surface before plasma cleaning;

Elektronikong industriya

Electronic components processing of plasma pretreatment, Paglilinis ng PCB, electrostatic LED support, IC paglilinis ng ibabaw at bonding

Industriya ng sasakyan

EPDM rubber strip spray lubrication coating or flocking glue pretreatment process; Plasma surface pretreatment technology is used for car headlight bonding, brake pad wiper, hood, instrument and bumper