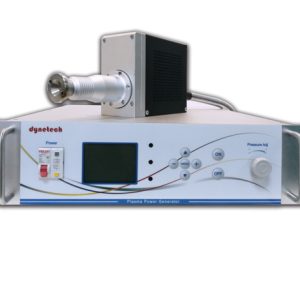

LRPM-V84 FPC Plasma Surface Treatment Machine

- Paglalarawan

- Pagtatanong

Paglalarawan

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

Mga katangian ng produkto

1. Baguhin ang mga katangian ng ibabaw ng mga materyales upang mapabuti ang pagdikit

2. It can be connected with the production line to realize automatic production

3 Low temperature plasma cold arc discharge technology

4. Optional multiple types of nozzles, wide range of use

5. Pagbutihin ang kalidad ng produksyon, pangangalaga sa kapaligiran at pag save ng enerhiya

6. Magandang seguridad, multifunctional na proteksyon sa kaligtasan

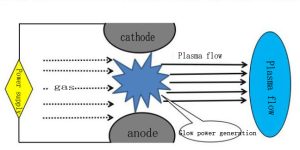

Plasma paglilinis prinsipyo: Ang teknolohiya ng paglilinis ng plasma ay gumagamit ng mga katangian ng mababang temperatura ng plasma upang makipag ugnay at mag react sa ibabaw ng materyal, so that the surface of the material being treated can be cleaned chemically and physically, mapabuti ang kahalumigmigan sa ibabaw, implant bagong kemikal functional na mga grupo at ibabaw etching.

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

Industriya ng aplikasyon

Photoelectric and electronic industry applications

1. Lahat ng uri ng paglilinis ng ibabaw ng salamin, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Nababaluktot at hindi nababaluktot na naka print na circuit board contact cleaning, LED floresan lampara “contact cleaning and improve the surface glue fastness;

3 Electronic components PCB cleaning, IC paglilinis ng ibabaw, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

Application ng industriya ng automotive

1. Automotive EPDM seal strip, flocking at pre coating pretreatment sa halip na gumamit ng base coating;

2. Base ng lampara ng kotse, mga groove, preno pad, bumper bonding, plasma pretreatment bago mag spray;

3 Bago ang paggamot ng gulong ng sasakyan anti puncture bago magdikit:

4. New energy automobile battery electrode welding, pag activate ng ibabaw ng patong, paglilinis, atbp

Application ng industriya ng plastik

1.PP, PVC, Alagang Hayop, PC, PE, PTFE and other plastic materials spraying, paglilimbag, pag electroplating, bonding and flocking pre-treatment;

2. Lahat ng uri ng plastic, silicone, goma na, pag spray ng metal at iba pang mga materyales, paglilimbag, plating bonding before surface modification, pag aalis ng mga pollutants sa ibabaw;

3. Pretreatment before printing and painting of mobile phones, mga computer, toys and other plastic shells to improve surface adhesion;

4. Plastic cosmetic bote preprocessing bago ang pag print, improve surface adhesion can prevent word falling off and improve product quality;

Application ng industriya ng packaging

1. Professional improvement of coated paper, glazing paper, buli na, baraha ng ginto at pilak, aluminyo plated papel, UV, OPP, PP, Alagang Hayop at iba pang mga kahon ng kulay, kahon ng kulay ibabaw paste box fastness;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Mga aplikasyon sa industriya ng pag print at coding

1. Plasma pretreatment bago pad printing, screen printing at jet coding sa ibabaw ng plastic, metal, glass and other composite materials to

improve the adhesion of material surface to ink;

2.PE, PTFE, silicone rubber wire and cable coding before processing 3.PVC, Alagang Hayop, ABS smart card coding before pretreatment

Application ng industriya ng appliance

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

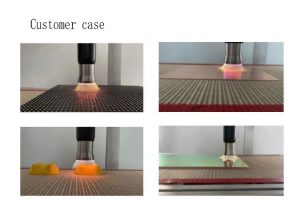

Customer case