SPV-20 Vacuum plasma paglilinis machine

- Paglalarawan

- Pagtatanong

Paglalarawan

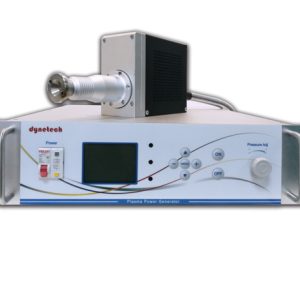

SPV-20 Vacuum plasma paglilinis machine

Outline:

Vacuum Plasma Cleaner(Panlinis ng plasma),the gas is separated into plasma state through the excitation power supply, and the plasma ACTS on the product surface to clean the pollutants on the product surface, so as to improve the surface activity and enhance the adhesion.Plasma cleaning is a new, pangangalaga sa kapaligiran, efficient and stable surface treatment.

SPV-20 Vacuum plasma paglilinis machine

Product feature:

1.Product placement fixture flexible, can adapt to irregular products

2.Horizontal electrode design can meet the requirements of soft product processing.

3.Low energy and gas consumption products.

4.Convenient way to put up and down the board

5.Vacuum system integration, maliit na bakas ng paa

6.Reasonable plasma reaction space, so that the treatment is more uniform

7.Integrated control system design makes operation more convenient

SPV-20 Vacuum plasma paglilinis machine

Industry application:

1.Mobile phone industry: TP, middle frame, back cover surface cleaning activation

2.PCB/FPC industry: hole drilling and surface cleaning, Coverlay surface coarsening and cleaning

3.Industriya ng semiconductor: semiconductor packaging, camera module, LED packaging, BGA packaging, 4.Wire Bond pretreatment

5.Ceramics: packaging, pre-treatment of glue

6.Surface roughening etching: PI surface roughening, PPS etching, semiconductor silicon chip PN junction removal, ITO film etching

7.Plastic materials: Teflon surface activation, ABS surface activation, and other plastic material cleaning activation

8.Clean the surface before applying ITO

SPV-20 Vacuum plasma paglilinis machine

Technical specifications

| Power system | Radio-frequency power supply | |

| Kapangyarihan | 0~300W | |

| Dalas | 13.56MHz | |

| Vacuum system

| Two-stage rotary vane pump (oil pump)

| 16m3/h |

| Vacuum line | All stainless steel piping, and high strength vacuum bellows | |

| Materyal | Aluminum alloy (customizable stainless steel chamber) | |

| Ang kapal | 25mm | |

| Leakproofness

| Military grade welding seal | |

| Internal dimension of cavity | 20L | |

| Available space spacing | 22.5mm | |

| Electrode plate layout | Horizontal layout, movable extraction | |

| Work tray | Standard set, material optional (aluminum, wire mesh) | |

| Gas system

| Flow range | 0~300SCCM |

| Process gas gas circuit | Standard with two channels, can be customized | |

| Sistema ng kontrol | Systems control | PLC |

| Delivery method | 7 inch touch screen | |

| The Other Parameter

| Boundary dimension | 900×1600×900mm(W×H×D) |

| Timbang | 150KG | |

| Device appearance color | silver gray | |

specification requirements

| Factory specification requirements | |

| Ac power specifications | Suplay ng kuryente:AC380V,50/60Hz,5mga linya,50A |

| Factory exhaust | Flow:2.0 m³/min |

| Gas requirements for factory work | Flow:1~10 L/min Presyon:3~7 kg/cm² Pipe diameter:6×4 mm Materyal: PU pipe Purity: above 99.99% |

| Factory compressed air requirements | Flow:1~10 L/min Presyon:3~7 kg/cm² Pipe diameter:8×5 mm Materyal: PU pipe Dew point: below -40℃ Particle>0.3μm:10Pcs/ft³ |

configuration list

| Configuration list | ||||

| Hindi | Pangalan | Paglalarawan | Unit | Qty |

| 1 | Host | Boundary dimension:900×1600×900mm(W×H×D) | Pc | 1 |

| 2 | Vacuum chamber | Aluminum alloy vacuum chamber | Pc | 1 |

| 3 | Excitation power supply | Radio-frequency power supply | Set | 1 |

| Dalas:13.56MHz; Kapangyarihan:0~300W Automatic vacuum capacitor matcher | ||||

| 4 | PLC | SIEMENS,S7-200 | Pc | 1 |

| 5 | touch screen | Vellon, 7 inch screen,MT6071iE | Pc | 1 |

| 6 | flowmeter | British Wawick brand | Pc | 2 |

| 7 | Vacuum pump | Flyover two-stage rotary vane pump (oil pump):40m3/h | Pc | 1 |

| 8 | vacuum gauge | INFICON

| Pc | 1 |

| 9 | Manual

| Operation manual of vacuum plasma cleaner SPV-20 | Pc | 1 |