Test method and application analysis of film flexibility

In the film industry, flexibility is a key performance indicator, which reflects the performance of the film in the face of external stress and deformation. The flexibility of the film directly affects its performance and durability in different application scenarios. This article will explore in depth the importance of flexibility, its testing methods, and its wide application in industry.

Test method of film flexibility:

Pagkalastiko: The elasticity of the film determines whether it can be restored under the action of external forces. This relates to the resilience of the film under stretching and compression.

Plasticity: The plasticity of the film is whether there is permanent deformation under the action of external forces. This is essential for certain application scenarios, such as coatings that need to undergo deformation.

Test method and application analysis of film flexibility

Pagdikit: The adhesion of the film indicates whether it adheres tightly to the surface of the substrate and is not easy to peel or crack.

Epekto ng paglaban: The ability of the film to resist rapid deformation, such as whether it is easy to break when an object strikes the surface of the coating.

Post-formability: The performance of the film in subsequent processing, such as whether it can maintain its flexibility and performance during the roll coating or molding process.

Flexibility test methods: In order to assess flexibility, a variety of test methods and instruments are widely used, the following are some common flexibility test methods:

Shaft rod tester: use steel shaft rods of different diameters, bend the coating template, and observe whether the coating is broken. The minimum available rod diameter indicates the flexibility of the film.

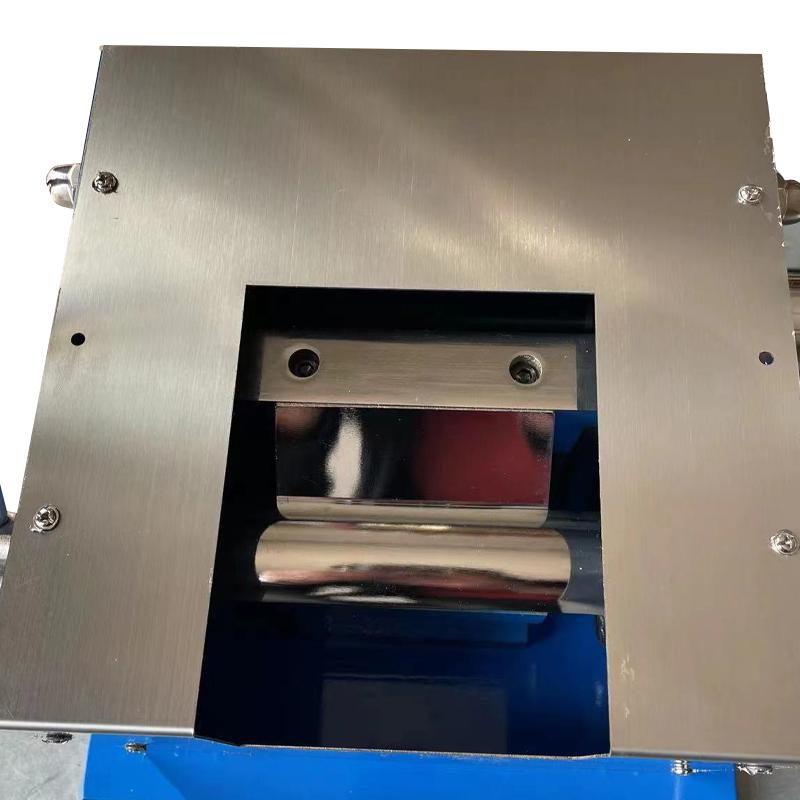

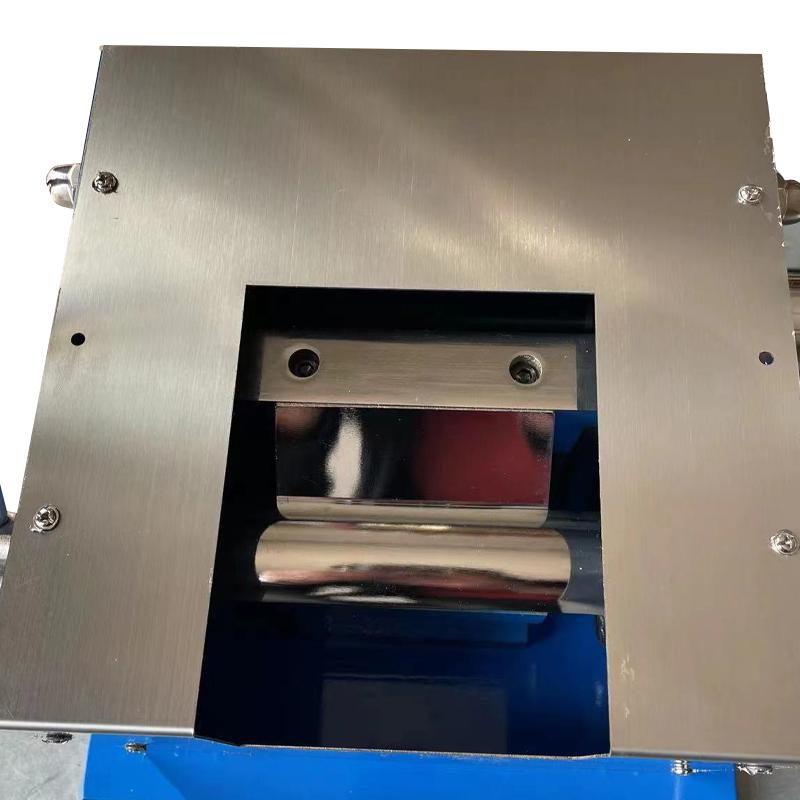

Cylindrical baras baluktot tester: A thin test plate is bent using a cylindrical shaft to assess its flexibility by observing whether the film is cracked or peeled.

Conical deflection tester: Use a cone to bend the coating template and observe the minimum diameter that causes the film to break. It is suitable for the whole board test and reduces the influence of human factors.

Cup test machine: Use a spherical punch to push the back of the painted test plate to observe whether it causes the film to crack or peel. Ang minimum na lalim ng pagtagos ay nagpapahiwatig ng kakayahang umangkop ng pelikula.

T-bending test: used for coil coatings, the test plate is folded to observe whether it is cracking, at pagkatapos ay patuloy na pagsubok ay isinasagawa, karaniwang minarkahan bilang 0T, 1T, 2T, atbp., na nagpapahiwatig ng kakayahang umangkop ng patong film.

Test method and application analysis of film flexibility

Test method and application analysis of film flexibility

Application of film flexibility

Film flexibility testing has a wide range of applications in the coatings industry:

Kontrol sa kalidad: Ang mga tagagawa ay maaaring gumamit ng pagsubok sa kakayahang umangkop upang matiyak na ang kanilang mga produkto ng patong ay may nais na tibay at kakayahang umangkop sa aktwal na paggamit.

Pagpili ng pintura: Ang mga tagagawa ay maaaring pumili ng mga uri ng pintura at formulations na angkop para sa iba't ibang mga application batay sa mga resulta ng pagsubok ng kakayahang umangkop.

Pagkatapos ng formability assessment: Flexibility testing can be used to assess the performance of the film during subsequent processing, tulad ng mga application sa roll coating at paghubog industriya.

Pag-unlad at Pagpapabuti: By understanding the flexibility characteristics, the research and development team can improve the coating formulation to meet the changing application needs.

Sa madaling salita, flexibility is an indispensable performance indicator in the coating industry and is crucial to ensuring product quality and performance. By choosing the right test method, manufacturers can better understand the flexibility of their coating products and meet customer needs. Ang pagpili ng pamamaraan ng pagsubok ng kakayahang umangkop ay dapat na batay sa tiyak na sitwasyon at pamantayan na kinakailangan upang matiyak ang katumpakan at paghahambing ng mga resulta ng pagsubok.