Ang pamamaraan ng pagsubok ng pintura ng pinong at ang paraan ng operasyon ng scraper fineness meter

panimula

Fineness is a key quality characteristic in the coatings industry, which is used to determine the size and dispersion of pigments and bulk pigments in coatings. The accurate measurement of fineness is essential to ensure the performance and quality of the paint. This article will describe how to use a scraper fineness meter to measure the fineness of paint, including the determination range, ang mga kinakailangang instrumento at materyales, the determination method, the result representation, and the reference standard.

1. Scope and description

Fineness is expressed in micrometers (M) and is used to describe the size and dispersion of the particles in the paint. Different coatings require fineness measurements in different particle size ranges. The method uses a scraper fineness meter to determine the fineness of the paint, and the method is suitable for the fineness of the color paint and the paint paste.

Ang pamamaraan ng pagsubok ng pintura ng pinong at ang paraan ng operasyon ng scraper fineness meter

2. Mga instrumento at materyales

(1) Scraper fineness meter: scraper fineness meter has different measuring ranges, including 0-25μm, 0-50M, 0-100μm and 0-150μm, as well as single and double slot specifications. Select the appropriate scraper fineness meter according to the paint fineness range.

(2) Minor paint knife or glass blender: used to stir the sample fully.

3. Determination method

(1) Select the appropriate scraper fineness meter: Select the appropriate scraper fineness meter according to the fineness range of the paint. Sa pangkalahatan, the 0-50μm scraper fineness meter is suitable for coatings with fineness below 30μm.

(2) Prepare the scraper fineness meter: Before use, the scraper fineness meter needs to be cleaned with solvent and wiped clean with a soft rag.

(3) Ihanda ang sample: use a minor paint knife or glass blender to stir the sample fully and evenly to ensure that there is no obvious particle aggregation in the sample.

(4) Drop the sample: Drop 2-3 drops of the sample into the deepest part of the groove of the scraper fineness meter to ensure that the sample is full of the groove and slightly redundant.

(5) To measure the scraper: hold the scraper with both hands and place it horizontally on the upper end of the scraper fineness meter bottom plate to ensure that the scraper and the bottom plate surface are in vertical contact. Pagkatapos ay, in 3 mga segundo, it is evenly scraped from top to bottom, ensuring that the sample is full of grooves and that no excess paint is left on the plate.

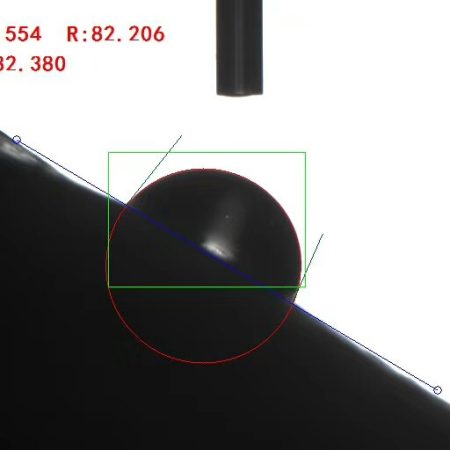

(6) Observation fineness: After the scraper is pulled, the Angle of view and the groove plane are formed into a 15-30° Angle, and the particles in the groove are evenly exposed to the light. Write down the degrees, accurate to the smallest scale. If there are individual particles exposed in other indexing lines, no more than 3 mga particle.

(7) Repeated measurement: Parallel measurement is performed for 3 beses na, and the arithmetic average of two close readings is taken as the fineness value of the paint. The error between the two readings should not be greater than the minimum index value of the instrument.

Ang pamamaraan ng pagsubok ng pintura ng pinong at ang paraan ng operasyon ng scraper fineness meter

4. Result presentation

The fineness of the paint is expressed by the groove depth (M) of the scraper fineness meter where the particles are evenly exposed. The fineness value should be no more than 3 particles within the range of adjacent indexing lines.

5. Mga pamantayan ng sanggunian

National standard GB/T 1724 “Determination of paint fineness”.

konklusyon

The fineness of the paint is an important quality characteristic, which reflects the size and dispersion of the particles in the paint. By using a scraper fineness meter, it is possible to accurately measure the fineness of the paint and ensure that the paint meets the required specifications. Fineness data is critical for the production and application of coatings, helping manufacturers and users to evaluate the performance and quality of coatings. Kaya nga, fineness measurement is an indispensable quality control step in the coatings industry, helping to ensure the consistency and reliability of coatings.