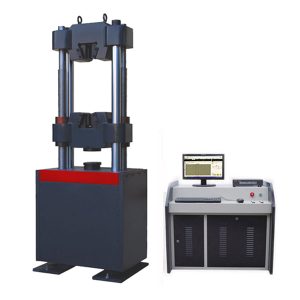

Machine d'essai universelle hydraulique à affichage numérique LR-WES-300B

- Description

- Enquête

Description

1,Introduction

The main engine is two columns, deux barres, cylindre d'huile, et l'espace d'étirement est au-dessus de l'hôte, and the compression and bending test space is between the lower beam of the host and the table.The measuring instrument adopts high definition LCD display, the experimental data is convenient and intuitive.

2.Transmission system

The lower beam can be adjusted by using the motor driven by the reducer, the chain drive mechanism and the screw side drive, and realize the adjustment of the drawing and compression space.

3,The hydraulic system

The hydraulic oil in the oil tank pumps the high-pressure pump into the oil circuit through the motor, which flows through the high pressure filter and sends back the oil valve and enters the cylinder.The measuring instrument collects and analyzes the data through the sensor, and shows the constant force value. The tester realizes the speed of the test force by controlling the flow through the oil delivery valve.

| Force maximale (kN) | 300 |

| Plage de mesure de la force d'essai | 4%-100% |

| Erreur relative d'indication de force de test | < The value for±1% |

| Maximum tensile test space(mm) | 600 |

| Espace de compression(mm) | 500 |

| Le coup de piston(mm) | 200 |

| Espacement des colonnes (mm) | 455 |

| The maximum clamping range of a round sample(mm) | Φ6-Φ26 |

| The maximum clamping thickness of flat sample(mm) | 0-30 |

| The maximum clamping width of flat sample(mm) | 75 |

| La taille de la plaque de pression (mm) | φ160mm |

| The maximum distance between two points of bending support(mm) | 300 |

| Bend the roll width(mm) | 140 |

| La méthode de serrage | Hydraulic automatic clamping |

| Taille du cadre principal (mm) | 750*600*2000 |

| Oil source console size(mm) | 600×500×1250 |

| Total motor power(kW) | 2 |

| The total weight(kg) | 1480 |