Penerapan viskometer putar dalam penentuan viskositas perekat

1. Perkenalan

In the process of production and application of adhesives, viskositas adalah indeks kinerja yang penting, which is directly related to its fluidity, construction performance and use effect. Karena itu, the accurate determination of adhesive viscosity is of great significance for product quality control and application effect. This paper will introduce the measurement method based on rotary viscometer.

2. Test principle and method

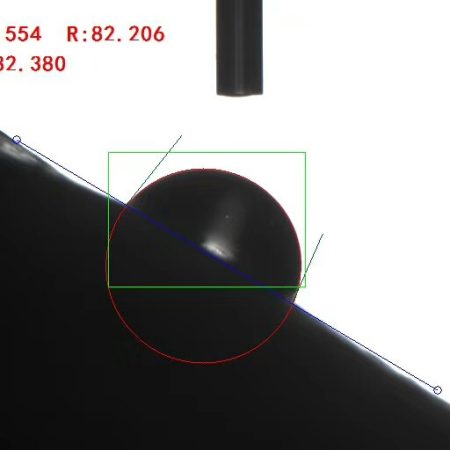

Dalam keadaan normal, high-viscosity liquids and viscous paint, latex paint, dll., have non-Newtonian flow properties, itu adalah, their viscosity will change with the shear rate. In order to determine the viscosity of adhesives, a rotary viscometer is usually used. By rotating the disk or blade and other parts, the instrument makes the sample produce rotary flow, and determines the stress required at a fixed shear rate, so as to calculate the viscosity value.

Penerapan viskometer putar dalam penentuan viskositas perekat

3. Peralatan

There are many kinds of rotary viscometers, which can be divided into different types according to the shape of the rotating parts, such as concentric disc type, internal and external simple rotation type, external and internal simple fixed type, slurry circular disc type and cone plate type. The thermometer is used to measure the temperature of the sample, with a separation of 0.1°C.

4. Poin operasi

In the determination of adhesive viscosity, it is necessary to pay attention to the following operating points:

Select the right rotor and speed: Select the right rotor and speed according to the viscosity of the sample, so that the measured value falls in the range of 20-80% of the dial.

Balance sample temperature: Ensure that the temperature of the sample is in balance with the test temperature, and keep the sample temperature uniform.

Dip the central part of the sample: dip the rotor vertically into the central part of the sample, and make the liquid level reach the rotor level mark.

Start the rotary viscometer: After starting the viscometer, observe the reading when the needle remains unchanged on the disc during rotation.

Penerapan viskometer putar dalam penentuan viskositas perekat

5. Result presentation and precautions

Each sample needs to be repeated three times, and the smallest value is taken as the test result, with three significant digits reserved. During the operation, note the following:

Loading and unloading rotors: Handling rotors should be handled with care to avoid excessive force causing the rotor to bend. After the rotor is installed, the instrument must not be placed sideways or upside down.

Keep clean: sekrup penghubung dan permukaan serta ulir ujung sambungan rotor harus tetap bersih, rotor harus dibersihkan tepat waktu setelah digunakan, dan ditempatkan dengan benar pada rangka rotor.

6. Penerapan dan signifikansi

Pengukuran viskositas perekat sangat penting dalam produksi, kontrol kualitas dan aplikasi:

Pengendalian produksi: Viskositas perekat berkaitan erat dengan formulasi dan parameter prosesnya, dan konsistensi produk dapat dikontrol melalui pengukuran viskositas.

Kinerja aplikasi: Viskositas perekat secara langsung mempengaruhi fluiditasnya, kinerja pelapisan dan daya rekat selama konstruksi dan penggunaan.

Kualitas asuransi: Pengukuran viskositas membantu menjamin kualitas perekat dan memastikan produk memenuhi persyaratan desain.

Penerapan viskometer putar dalam penentuan viskositas perekat

7. Kesimpulan

Penentuan viskositas perekat merupakan bagian yang sulit atau hilang dalam industri perekat. Melalui metode pengukuran viskometer putar, nilai viskositas perekat dapat diperoleh secara akurat, yang memberikan referensi penting untuk produksi dan penerapan produk, sehingga meningkatkan kinerja dan kualitas produk.