ISO 4520-1981 Chromate conversion films for electrogalvanized and electroplated Cadmium Layers

Chromate conversion film GB9800-88 for electroplated zinc and cadmium layers

This standard is equivalent to international standard IS04520-81« Chromate conversion film with electroplated zinc and cadmium layers ».

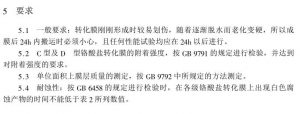

Subject content and scope of application

This standard specifies specific requirements for chromate conversion films for corrosion protection on electrogalvanized and electroplated coatings.

This STANDARD does NOT APPLY to surface FINISHES that merely provide a special color or are intended to improve paint adhesion strength.

2 Reference standards

Metal cover neutral salt spray test (Nss test)

Test method for chromate conversion films on zinc and cadmium

Conversion film on metallic materials — Determination of the mass of the film per unit area — Gravimetric method

ISO 4520-1981 Chromate conversion films for electrogalvanized and electroplated Cadmium Layers

3 Film forming method

After electroplating zinc or cadmium, it is usually treated by chromate solution leaching to form chromate conversion film.

Chromate solution is acidic and contains hexavalent chromate and other salts that improve the appearance, hardness and corrosion properties of the film.

The color, type and performance of chromate conversion film are determined by the composition of the solution, but are also affected by pH value, temperature, treatment time and coating quality. Electrogalvanized or electroplated cadmium layer in the appropriate solution to form thick corrosive high rainbow color or dark color chromate conversion film and thin corrosive low bright, clear chromate conversion film, electrogalvanized layer can also be obtained by the method of color film in alkaline solution, phosphoric acid or lattice acid solution to obtain bright, clear chromate conversion film.

ISO 4520-1981 Chromate conversion films for electrogalvanized and electroplated Cadmium Layers

It is difficult for electroplating workers to ensure that the chromate conversion film with accurate tone is provided. If accurate tone is required, white chromate film can be stained, but the corrosion performance is only similar to that of white conversion film.

In order to prevent the dissolution of hexavalent chromium, the hot water temperature should not be higher than 6o℃, and the label washing time should be as short as possible.

In order to prevent the film from cracking due to dehydration, the drying temperature should not exceed 60℃.

If hydrogen removal is required, it should be done before the formation of the chromate conversion film.