段ボール性能試験科目と試験設備

段ボールは表面紙を3層重ねた紙素材です。, 段ボールの芯紙と底紙, which is mainly used to make various types of carton, cardboard and other packaging materials.

The main performance of corrugated paper includes the following aspects:

強さ: Corrugated paper needs to have high strength to ensure that the carton, cardboard and other packaging materials made can withstand the weight of goods and vibration and vibration during transportation. Strength detection can be carried out by measuring the tensile strength, compressive strength and other indicators of corrugated paper.

厚みと均一性: The thickness and uniformity of corrugated paper have an important impact on the dimensional stability and bearing capacity of carton, cardboard and other packaging materials made. The detection of thickness and uniformity can be carried out by measuring the thickness, density and basic weight of corrugated paper.

Shape stability: Corrugated paper needs to have a certain shape stability, in order to ensure that the carton, cardboard and other packaging materials are not easy to deformation or deformation is small. The shape stability can be detected by measuring the elastic modulus, 曲げ, rebound rate and other indicators of corrugated paper.

段ボール性能試験科目と試験設備

Printable: Corrugated paper needs to have a certain printable ability to ensure the printing quality of carton, cardboard and other packaging materials. The printability can be tested by measuring the printing suitability, printing quality and printing speed of corrugated paper.

耐水性: Corrugated paper needs to have a certain water resistance to prevent it from deforming or losing strength in humid environments. The detection of water resistance can be carried out by measuring the water absorption, toughness and other indicators of corrugated paper.

環境を守ること: corrugated paper needs to meet environmental protection standards, do not contain harmful substances, 環境への汚染がない. The detection of environmental protection can be carried out by measuring the volatile organic compounds, ヘビーメタル, chloride ions and other indicators of corrugated paper.

段ボール性能試験科目と試験設備

Packaging performance: The packaging performance of corrugated paper is one of its important performance indicators, including packaging tightness, 寸法安定性と積層安定性. The detection of packaging performance can be carried out by measuring the corrugated height, 波形形状, ボール紙の硬さ, foldability and other indicators.

Stretchability: Corrugated paper needs to have a certain stretchability to ensure that it is not easy to tear or rupture when it is made into carton, cardboard and other packaging materials. Tensile testing can be carried out by measuring the tensile strength, tensile resistance and other indicators of corrugated paper.

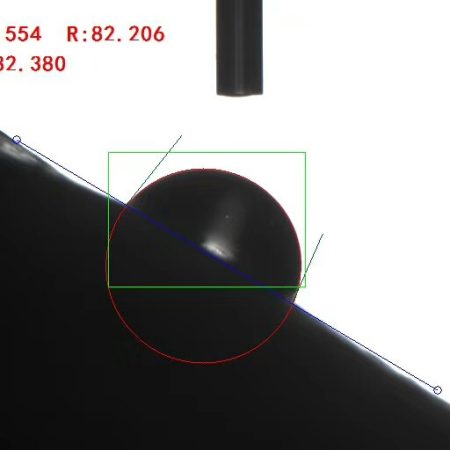

Corrugated shape: The corrugated shape of corrugated paper has an important impact on the carrying capacity and shape stability of carton, cardboard and other packaging materials. The detection of corrugated shape can be carried out by measuring the corrugated height, corrugated width, corrugated shape and other indicators.

適用範囲: Corrugated has a wide range of uses, involving the production of various types of carton, cardboard and other packaging materials, 特定のアプリケーション要件に従ってテストおよび評価する必要がある. The detection of the scope of application can be carried out by measuring the applicable environment, applicable carton type and applicable processing technology of corrugated paper.

段ボール性能試験科目と試験設備

検出性能

Different kinds of paper need to use different detection methods and instruments in the detection. The following are some commonly used paper performance testing methods:

Detection of base weight: calculate the base weight per square meter by weighing the weight of a certain size of paper. 測定は計量器を使用して行われました.

厚みと均一性の検出: The thickness of the paper is measured by using a manual or automatic thickness gauge, while the uniformity is detected by laser or machine measurement methods.

強度試験: through the use of paper strength testing equipment, 電子引張機など, 多機能試験機, 破断強度試験機, 等, to measure the tensile strength of paper, 圧縮強度, 曲げ強度, rupture strength, 等.

Surface coating testing: through the use of surface coating testing instruments, such as scratch tester, wear resistance tester, adhesion tester, 等, to measure the surface coating uniformity, 硬度, wear resistance and adhesion properties.

Sliding detection: through the use of sliding testing instruments, such as sliding coefficient tester, friction coefficient tester, 等, to measure the surface smoothness of paper and friction coefficient and other properties.

段ボール性能試験科目と試験設備

包装性能試験: 包装性能試験機の使用による, 波形圧縮試験機など, 波形曲げ試験機, スタッキングテスター, 等, to measure the carton, cardboard and other packaging materials compression strength, 曲げ強度, スタッキング安定性およびその他の特性.

Printability testing: through the use of printing quality testing instruments, 印刷精度検査器など, 印刷スピードテスター, インキ密着試験機, 等, to measure the performance of paper printing quality, printing speed and ink adhesion.

Corrugated paper performance test subjects and equipmentthrough the use of environmental testing instruments, 揮発性有機化合物試験器など, 重金属テスター, 塩化物イオン測定器, 等, 揮発性有機化合物の含有量を測定する, ヘビーメタル, chloride ions and other harmful substances in paper.

The above methods are only a part of the paper performance detection, the specific detection methods and instruments need to be selected according to different paper types and performance indicators.