- 설명

- 문의

설명

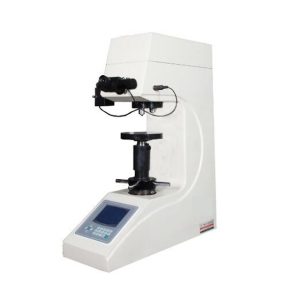

HR-45A Rockwell Hardness Tester

모델 개요

HRSS – 45A digital ROCKWELL hardness tester set all ROCKWELL, superficial ROCKWELL, plastics ROCKWELL can work more hardness tester, using ROCKWELL (ROCKWELL) measuring principle, can be directly for ROCKWELL, superficial ROCKWELL, plastics ROCKWELL hardness measurement.Suitable for carbon steel, alloy steel, 주철, non-ferrous metal and engineering plastic material such as hardness testing, 높은 측정 정밀도로, 넓은 측정 범위, automatic unloading the main test force, measure the digital display and automatic printing or with external computer communication, etc.Can be widely used in the measurement, 기계 제조, 화학 산업, building materials and other industries testing, 연구와 생산.

HR-45A Rockwell Hardness Tester

제품 특징

제품의 몸체 부분을 캐스팅 공법으로 성형하여 오랜 시간 동안 처리하였습니다. 지깅 공법에 비해, 모양 변수의 장기간 사용은 매우 적습니다., 다양한 가혹한 환경에 효과적으로 적응할 수 있습니다.;

자동차 페인트, 고품질 페인트, 긁힘에 강한 저항, 몇년이 지나도 여전히 새것처럼 밝아요;

The core parts are fully CNC machine parts, and the precision and stability of the machine are greatly improved.

The hardness tester has 8-inch touch screen display and STM32 single chip microcomputer control system, which can realize man-machine dialogue and automatic operation.It has high test precision, 간단한 조작, 고감도, easy to use and stable indicator.

Electronic closed-loop control exerts experimental force;The application of test force, unloading and hardness value are fully realized.

STM32 has the advantage of high frequency, fast and suitable for large amount of data processing and storage, fast refresh LCD interface, system anti-interference ability compared with C51 system more stable, 더 듬직 해요, error probability is low, the biggest advantage of STM32 embedded operating system, unstable dead when systems affected by external interference, able to handle errors;

The built-in test software can compensate for the hardness of the machine, so that the adjustment of the micro-deviation can not be used to open the machine cover for mechanical adjustment, reducing the use and after-sales service cost.

It can be automatically converted to the hardness value of other ruler according to the measured rockwell hardness value, and no longer need to waste time and energy to query the tedious hardness comparison table;

Built-in printer to read relevant test results.Automatic operation is realized to eliminate manual operation and reading error.

The accuracy is in accordance with GB/T230.2, iso6508-2 and ASTM E18.

적용 범위

Determination of rockwell hardness of ferrous metals, nonferrous metals and non-metallic materials.

Determination of plastics. Hardness of composite materials and various friction materials and soft metals, non-metallic materials, 등.

Determination of surface rockwell hardness of black metal, alloy steel, hard alloy and metal surface treatment (carburizing, nitriding, electroplating layer).

주요 기술 매개변수

측정 범위: 20-88hra, 20-100hrb, 20-70hrc;

HRL hre, 70-100, 50-70, 50-115 HRM, 50-115 HRR,

Hr15t hr15n, 70-94, 70-70,

Hr30t hr30n 42-86, 29-86,

Hr45t hr45n 20-77, 10-77

시험력: 588.4, 980.7, 1471N (60, 100, 150kgf);

147.1, 294.2, 441.3N (15, 30, 45kgf)

Maximum height: 180mm;

Head center to machine wall distance: 165mm;

Hardness resolution: 0.1HR;

치수: 510*290*730mm;

전원 공급 장치: AC220V / 50 hz

무게: 85 킬로그램

Accessory box standard

주인: 1 1/16″ steel ball head: 1.

Standard hardness block of A ruler: 1 1/16″ spare steel ball: 5.

B scale standard hardness block: 1 piece of 120 ° diamond cone head: 1

C standard hardness block: 3 pieces of circular flat surface: 1.

15N standard hardness block: 1 block V working sample table: 1.

Standard hardness block of 30N scale: 2 power lines: 1.

Standard hardness block of 30T scale: 1 piece of instrument cover: 1.

Screwdriver for head mounting: 1.