- 설명

- 문의

설명

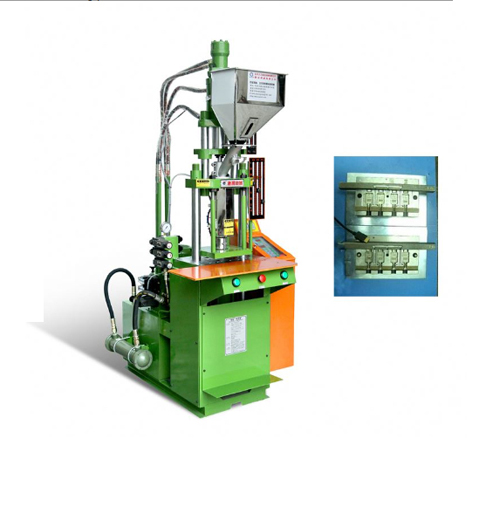

플라스틱 수직 사출 성형기

비rief introduction:

LR-350ST injection molding machine is the main molding equipment to make plastic products of various shapes by thermoplastic or thermosetting plastics using plastic forming molds.Divided into vertical, horizontal, 가득한 – electric.The injection molding machine heats the plastic, applying high pressure to the molten plastic so that it is shot out and fills the mold cavity.

플라스틱 수직 사출 성형기

특성:

1, straight screw injection device.

- 두번째 (third) section temperature control, fast firing rate, back pressure, screw rotation without section adjustment, suitable for various precision plastic parts forming.

- The lower mold fixes the upper mold movement, which has good positioning for the inlaid articles, and has the finished product ejector device.

- Low-pressure die closing device protects mold safety.

- LCD display screen.

플라스틱 수직 사출 성형기

제품 설명:

- Vertical mold opening, vertical injection, suitable for insert molding

- Nitrided steel screw, material tube, high torque hydraulic motor drive, multi-stage injection pressure, good plasticizing performance.

- Direct pressure mother-mold lock cylinder design, rapid mold clamping, low-pressure safety mold clamping, automatic mold closing, multiple pressure control, high safety and improved mold life.

- Electrical protection device, no mistakes, maintenance operator safety.

- Automatic fault display, maintenance is quick and easy.

- Electronic control and hydraulic use brand-name parts, quiet, precise and durable.

- Multi-stage temperature control, multi-stage injection pressure, rate of fire, back pressure stepless adjustment, suitable for molding of precision plastic parts.

- Optional servo energy-saving motor.

- This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production.

10 Two column and four column (option)

플라스틱 수직 사출 성형기

기술적인 매개변수:

모델 | UNIT | JY-160ST | JY-200ST | |||||

| 주입 시스템 | The screw diameter | Mm | 26 | 28 | 30 | 30 | 32 | 35 |

| Injection Pressure | kg/c㎡ | 1530 | 1278 | 886 | 1171 | 996 | 810 | |

| Theoretical injection capacity | 센티미터 | 61 | 70.8 | 81 | 81 | 92 | 117 | |

| Injection quantity(PS) | g | 56 | 64 | 74 | 74 | 84 | 106 | |

| Injection quantity(PS) | OZ | 2 | 2.3 | 2.6 | 2.6 | 3 | 3.8 | |

| Injection rate | cm/sec | 57 | 66 | 76 | 62.5 | 71 | 95 | |

| Screw the trip | mm | 115 | 115 | |||||

| Screw revolution | rpm | 0-205 | 0-190 | |||||

| Nozzle contact force | Tons | 4.45 | 4.45 | |||||

| Nozzle trip | mm | 170 | 190 | |||||

| Number of temperature control sections | 3 | 3 | ||||||

| Clamping system | Clamping force | Tons | 35 | 45 | ||||

| Board size | mm | 450X280 | 480X310 | |||||

| Die column spacing | mm | 265 | 295 | |||||

| Minimum modulus of thick | mm | 100/25 | 100/60 | |||||

| Opening stroke | mm | 190 | 180 | |||||

| Maximum die spacing | mm | 290/215 | 280/240 | |||||

| Ejection pressure | Tons | 1.5 | 1.5 | |||||

| Ejection stroke | mm | 135 | 135 | |||||

| Power electrothermal system | Maximum hydraulic pressure | kg/c㎡ | 140 | 140 | ||||

| Pump discharge volume | l/분 | 34.5 | 37.2 | |||||

| As a dynamic oil Quantity | 엘 | 100 | 130 | |||||

| Cooling water consumption | l/hr | 400-600 | 600-800 | |||||

| The motor power | KW/HP | 3.75/5.5HP | 5.5/7.5HP | |||||

| The electric capacity | KW | 2.4 | 2.8 | |||||

| The total power consumption | KW | 6.3 | 9 | |||||

| Else | 기계 중량 | Tons | 1.7 | 2.6 | ||||

| Mechanical dimensions | 중 | 1.5×1.05×2.72 | 1.8X1.25X3.08 | |||||

| Pay the ship weight | Tons | 2 | 2.9 | |||||

| Pay the ship size | 중 | 1.8X1.3X2.3 | 2X1.45X2.3 | |||||