- Description

- Inquiry

Description

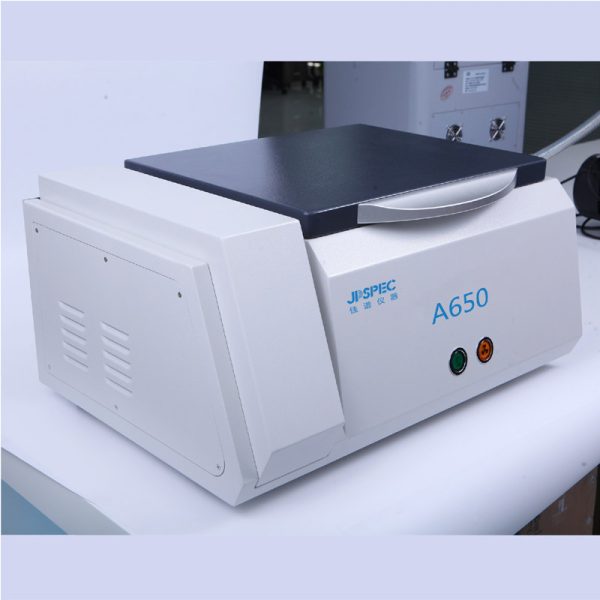

A650 magnetic material analyzer accurately detects Fe203 in magnetic materials

1~120s completes the accurate analysis of dozens of elements synchronously between Na and U

A650 Benchtop Magnetic material analyzer X-ray fluorescence analyzer

Fe203

Iron red (main component is Fe203). Iron oxide, alias burnt limonite, iron Dan, iron red, the main composition of iron oxide, iron oxide and so on. Chemical formula Fe203, dissolved in hydrochloric acid, red brown powder. Its red brown powder is a kind of low pigment, industrial called iron oxide red, used in paint, ink, rubber and other industries, can be used as catalyst, glass, gem, metal polishing agent, can be used as iron making raw materials, etc. The analysis of trace elements in iron red by chemical titration method is complicated and time-consuming. The composition of Fe203,Si02,Ca0, Mn0 and CI in iron red has been tested by X-ray fluorescence spectrometer (XRF) with tablet pressing method, and the stability is good.

A650 Benchtop Magnetic material analyzer X-ray fluorescence analyzer

Application field

1.Magnetic material

2.Ore analysis

3.Alloy detection

4.Detection of harmful elements (RoHS, halogens)

5.Total element analysis

A650 Benchtop Magnetic material analyzer X-ray fluorescence analyzer

Technical specification

Performance characteristics

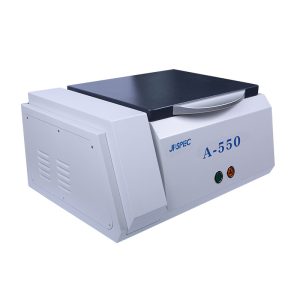

1. Appearance design: generous and beautiful, durable, multiple safety protection mode

2. Collimating filter system: collimating + multi-combination filter, software automatic switch, meet a variety of test applications

3. SES signal processing system (digital multi-channel) developed by ourselves is adopted to effectively improve the peak back ratio and make the measurement more accurate

4. Multi-dimensional heat dissipation system: Optimize the integrated heat dissipation design to improve the heat dissipation performance of the whole machine and ensure the operation safety of the X-ray source

5. Radiation safety system: multiple anti-radiation leakage design, radiation protection level belongs to the highest of similar products vacuum system: optional pumping

6. Vacuum system optimizes the test environment, improves the analysis accuracy of light elements such as magnesium, aluminum, silicon, phosphorus and sulfur, and greatly expands the analysis capability of A650 analyzer

7. Unique movement temperature monitoring technology ensures the safe and reliable operation of the ray source, effectively prolongs its service life and reduces the use cost

Hardware advantage

The whole set of core components is imported

1. Detector: the complete silicon drift SDD detector of the United States, with the lowest resolution to 130eV, excellent energy linearity and energy resolution, peak-to-back ratio

2. X-ray tube: maximum power 50W, tube voltage 5-50KV, tube current 0-1000uA; Long life X-ray tube

3. High voltage power supply: maximum power 50 W, voltage 0-50 KV, current 0-1000uA. 8-hour stability ≤0.05%

4. Signal processor: Adopt imported signal processor, adapt to high resolution and high count rate, self-tuning magnification, the maximum number: 4096

Software advantage

Advanced fluorescence analysis software Chinese version, the software integration of empirical coefficient method, theoretical coefficient method, linear fitting, quadratic curve, intensity correction, content correction and other analysis methods, to fully ensure the accuracy of test data.

Instrument configuration

System standard configuration

1.SDD detector

2. X-ray sources

3. High voltage power supply

4. Sex to noise ratio electronic circuit system

5. Optical path enhancement system

6. Filter group + collimation

7. Digital multichannel analyzer

8. Brand vacuum system

9. Branded inkjet printers

10. Branded computers

11.X fluorescence full element analysis software

12. Sample cup and fuse

System selection

1. Special Grinding machine for spectrum (optional)

2. Spectroscopic Fusion Machine (Optional)

4. Fused platinum heap collapse (optional)

5. Special Tablet press for spectrometer (optional)

3. Special Powder Making machine for Spectrum (optional)