ASTM D6195 Adhesive Tape Loop Tack Tester

- Description

- Inquiry

Description

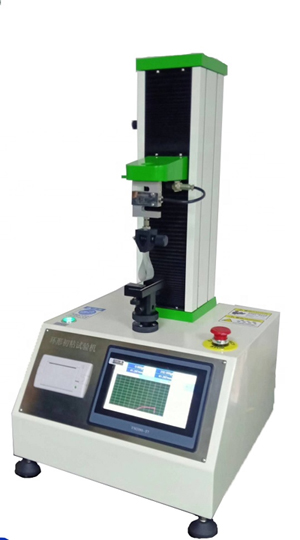

ASTM D6195 Adhesive Tape Loop Tack Tester

Product description:

Adhesive Tape Loop Tack Tester ,compact and exquisite structure, high precision sensors and motors, top core accessories.Can allow users to quickly and effectively determine adhesive tape, label and other products adhesion and adhesion.Mainly used for various adhesive tapes, adhesives and other products of the initial adhesion.The products meet international standards such as FINAT Test Method No. 9: Loop Tack Measurement, TLMI, ASTM, etc., suitable for research institutions, adhesive import and export enterprises, inspection and quarantine institutions, etc.

ASTM D6195 Adhesive Tape Loop Tack Tester

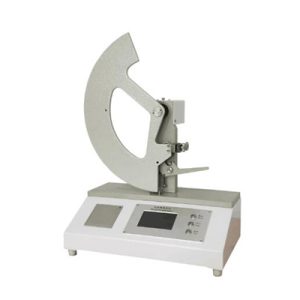

Test principle:

After the annular sample is completely contacted with the standard float glass test plate at a constant speed of 300mm/min, the instrument automatically separates the annular sample and the test plate in reverse at a constant speed of 300mm/min. The maximum force generated is the initial adhesion of the annular sample.

ASTM D6195 Adhesive Tape Loop Tack Tester

Main Features:

1. Microcomputer is used to control the whole test process and real-time dynamic display of load value, displacement value, variation value and test speed;

2. Use microcomputer for data processing and analysis, and the test results can be saved automatically.After the test, the maximum force, hysteresis loop method, stepwise approximation method, non-proportional extension strength, tensile strength, compressive strength and elongation rate are calculated automatically.

3, all Chinese Windows platform test software, with strong data maximum, minimum, average, net energy, back energy, total energy, bending modulus, breakpoint displacement X % load, breakpoint load X % displacement, etc.Data backup: Test data can be saved on any hard disk partition.After the end of the test, the test curve can be called out again. The completed test report and test curve can be printed out in real time through the function of curve traversal and graph processing.

4. The full-digital, three-closed-loop (force, deformation, displacement) control system based on neuron adaptive PID algorithm is adopted to realize the full-digital three-closed-loop control of force, deformation, and displacement. The control rings can be automatically switched between each control ring, and there is no excessive impact smoothness in the test when switching between various modes;

5. Control and maintain the test force, deformation, displacement and other rates;

6. Online identification of test control parameters;

7. High precision data acquisition system with high resolution;

8. Standard USB interface is adopted for all interfaces except the power interface, with neat and reasonable layout and convenient plugging and unplugging.

9. Load displacement curve, load, time curve, displacement, time curve, stress and strain curve;

10. The decimal number can be set, (two and three digits) each physical unit and password protection, etc.;

11. The test report language can be converted from Chinese to English;

12. Overload emergency stop device, upper and lower travel limit device, leakage automatic power off system, automatic breakpoint stop function.

Technical parameters:

1. Load range: 0-200N (optional configuration: 10N 20N 50N 100N 200N 500N)

2. Precision: ≤0.5%

3. Resolution: 0.01n

4. Loading speed: 300mm/min (0.5 ~ 500mm/min adjustable)

5. Size of test plate: 30.00mm×25.00mm×1.6mm(length, width and thickness)

6. Sample size: 150.00mm×25.00mm

7. Power unit switch: KGF, GF, N, kN, LBF

8. Power rate: 120W

9. Power source: 220V 50Hz

10. External dimension: 300mm (B) ×380mm (L) ×410mm (H)

11. Net weight: 25Kg

National standard: ASTM, TLMI, FINAT

Standard configuration of ring primer: host, power cord, fixture, test board 3 pieces.