ASTM D6927 Marshall stability tester

- Description

- Inquiry

Description

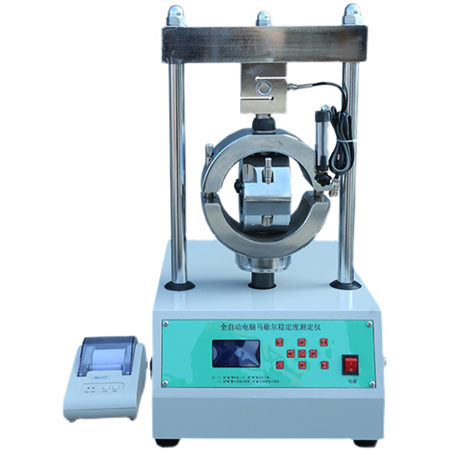

ASTM D6927 Marshall stability tester

Detailed description:

LWD – 3 Marshall stability tester is suitable for the asphalt mixture thermal stability and ability to resist plastic deformation stability and flow values, can provide the matching data for asphalt mixture, my company production of Marshall stability test apparatus, simple operation, good appearance, accurate testing, instrumentation, various types of asphalt for buyers to choose major suppliers.

The LWD-3 Marshall stability tester is based on the Highway Engineering and Asphalt Mixture Test Specification jTL052-2000 of the Ministry of Communications. It is suitable for Marshall stability test and immersion Marshall stability test to carry out asphalt mixture mix design or asphalt pavement construction quality inspection. The immersion Marshall stability test (or vacuum Marshall test if necessary) is used to test the ability of asphalt mixture to resist spalling when subjected to water damage, and to test the feasibility of the mix design by testing its water stability. The instrument is suitable for measuring the thermal stability of asphalt mixture and the ability stability and flow value of anti-plastic denatured type, which conforms to the standard of “Highway asphalt and asphalt mixture test Specification JTJ052-2000”. LCD screen display, dynamic display test curve, Chinese display all kinds of test data, intuitive and convenient; Full digital calibration of pressure and flow value, without manual adjustment of the potentiometer; Automatic protection function against wrong operation and overpressure, will not appear because of overpressure and damage the instrument;

ASTM D6927 Marshall stability tester

Test method for LWD-3 Marshall stability tester

(1) Standard Marshall test method

1 measured with a caliper (or specimen height tester) specimen diameter and height (such as the specimen height do not conform to the requirements of the (63.5 and 1.3) mm height difference on both sides or greater than 2 mm, the specimen shall be invalid), and the determination of physical indexes of the specimens according to the requirements of specification (apparent density, theoretical density, void ratio, asphalt percentage by volume, void in mineral aggregate and asphalt saturation, etc.).

2 Adjust the constant temperature sink (or oven) to the required test temperature (for viscous petroleum asphalt mixture is (60 1) ℃). The specimen was placed in a constant temperature flume (or oven) with a temperature of 30 ~ 4Omin. Specimens should be cushioned, not less than 5cm from the bottom of the container.

3 Put the upper and lower pressure head of the Marshall tester into the sink (or oven) to reach the same temperature. Remove the upper and lower pressure head from the sink (or oven) and wipe the inner surface dry. To allow the upper and lower head to slide freely, apply a small amount of butter to the guide rod of the lower head. Then the specimen is softened and taken out and placed on the lower pressure head, covered with the upper pressure head, and then installed on the loading equipment.

4 Install the flow value measuring device on the guide rod, make the guide casing gently press the upper pressure head, and set the flow value meter reading to zero. Place the steel ball on the ball seat of the upper pressure head and align the pressure head of the load measuring device (stress ring or sensor), then align the dial indicator in the stress ring to zero or reset the load sensor reading to zero.

ASTM D6927 Marshall stability tester

Technical parameters:

1. The vertical rising speed of the tray of the test instrument is 50±5mm/min

2. The large moving distance of the tray of the test instrument is 70mm

3. Working range of force value: 0-50.00KN

4, flow value working range: 0-20.00mm

5, force measuring device measurement accuracy ±0.1kN

6, flow value measurement device measurement precision 0.01mm

7, working voltage: AC 220V

8, motor specifications: 220V, 0.37KW, 1440RPM, single-phase operation

9, large rated load: 50KN

10, operating conditions: ambient temperature 0℃-60℃ relative temperature < 85%