BGD 539 Automatic Scribe Marks Machine for Corrosion Testing

- Description

- Inquiry

Description

BGD 539 Automatic Scribe Marks Machine for Corrosion Testing

Description

In the corrosion testing of different coatings, we always need to prepare a specific scribe marks on the coating surface. Manual cutting often lead to defects, such as non-straightness scribe marks, damaged edges of the scribe marks, inconsistent damage to the substrate. These defects may have a random influence on the test results. Moreover, when we cut the scribe marks on the multilayer coating, manual operation becomes more difficult, it cost more time and difficult to obtain a uniform scribe mark.

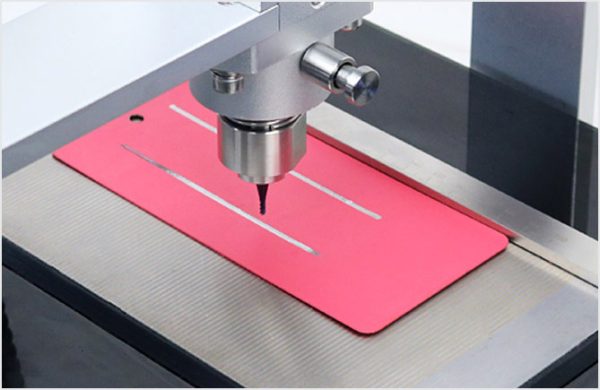

For the corrosion resistant coating, its neutral salt spray testing demands a vertical 2mm scribe mark. BGD 539 Automatic Scribe Marks Machine for Corrosion Testing can make this scribe mark easily, moreover, it has the following characteristics:

◆ 2mm wide vertical scratch, strictly comply with the standard.

◆ The cutting blade adopt rotary cutting principle to ensure the edge of the prepared scratch is neat and without damage.

◆ The cutting blade is floating design, can load different thickness test panel, and can minimize the damage of the substrate.

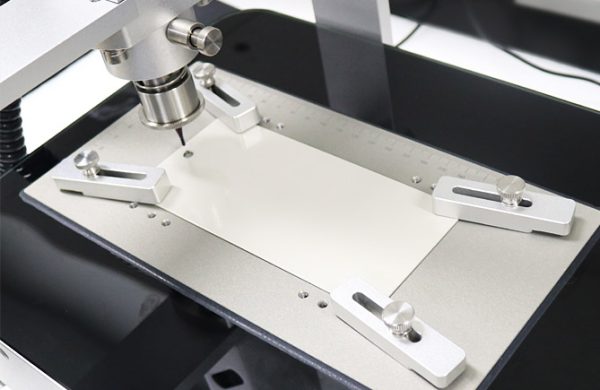

◆ Permanent magnet working platform, easy to load the magnetic substrate.

◆ With scale indication, easy to cut different size scratch.

BGD 539 Automatic Scribe Marks Machine for Corrosion Testing

Main Technical Parameters

■ Working Distance:0~150mm;

■ Scribe mark Depth:0~2000μm;

■ Test panel Thickness:0~5mm(include the thickness of the coating)

■ Overall Size:374mm×320mm×410mm;

■ Working Platform Size:250mm×125mm;

■ Ordering information:BGD 539—Automatic Scribe Marks Machine for Corrosion Testing

Note:Biuged can customize this machine for special scribe mark, including different working platform size, different working distance.