JBW-300B Microcomputer metal impact testing machine

- Description

- Inquiry

Description

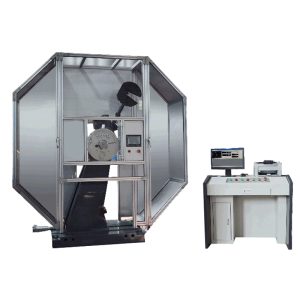

JBW-300B Microcomputer metal impact testing machine

1.project brief:

JBW-300B microcomputer control screen display impact testing machine is a new product developed by our company in strict accordance with the testing method of GB/ t3038-2002 « pendulum impact testing machine » and GB/ t229-2007 « metal charpy notch impact test method.It is an ideal instrument for measuring the impact resistance of metal materials under dynamic load.The device can automatically control the operation of pendulum, impact and pendulum, and the display mode is double explicit: namely, the dial pointer and the computer are displayed simultaneously, and the test results, such as batch or successive printing of impact absorbing power and impact toughness, are compact and easy to operate.The maximum impact energy of the equipment is 300J and equipped with 150J pendulum hammer.

JBW-300B Microcomputer metal impact testing machine

2.Description Schemes:

The working principle of the equipment is to use a high-precision photoelectric encoder and a computer with special measurement and control and calculation software to detect the difference between the potential energy before and after the impact of the pendulum to detect the impact absorbing power and the impact toughness of the material.Display mode is double explicit: namely, dial pointer and computer display simultaneously.Computer can display shock absorption function, impact toughness, and can make automatic test data processing, the automatic generation of test reports, take place, pin, shock, to put place such as action control can be either by hand control box of manual control, also can use a computer program by mouse input automatic control, and can batch or successive print test results.

The equipment adopts PLC as the lower computer control, brand computer as the upper computer control, upper computer program adopts VB programming and RS232 communication method to complete the data exchange and command transfer of the upper and lower computers, making full use of the powerful functions of PC for data processing, report processing and so on.The rotary encoder with high precision is used to obtain the real-time position of the pendulum and obtain the shock absorption power.It has the characteristics of system reliability, stability and data accuracy.

JBW-300B Microcomputer metal impact testing machine

3.Character

Host Machine

- u Tester host for single supporting pillar type structure, cantilever hang put way, u-shaped pendulum hammer body;

- u Shocks knife used screw fixed installation, simple replacement;

- u Sample beam type bearing;

- u Host is equipped with safety pins, and equipped with a security fence.

- u Microcomputer control, according to the instructions to complete take place, impact, automatic place, then the whole process of impact test.

4.Technical Specification

| Maximum impact energy | 300J |

| Maximum impact speed | 5.2m/s |

| Pendulum Angle | 150゜ |

| The distance between the spindle and the strike center | 750mm |

| Sample support span | 40mm |

| The arc radius of the bearing end of the sample | R1—1.5mm

|

| Impact blade radius | R2—2.5mm |

| The Angle between the two bevel of the impact knife | 30º |

| Impactor thickness | 16mm |

| Power | 50Hz 380V 250W

|

| Weight | 480kg |

| Rate of power | 180W |