K-8000T coating thickness analyzer

- Description

- Inquiry

Description

K-8000T coating thickness analyzer

K-8000T Handheld coating thickness analyzer,Elemental analyzer of metal composition

Trade description

Quality control in the process of industrial production, high voltage isolation switch contact silver layer detector, copper silver plating, tin plating thickness rapid test, and meet the element analysis of metal composition. Professional nondestructive testing as a quality control and management in the production process, to ensure the quality of materials; Identification of alloy components in shipbuilding, aerospace and other high-tech industries to ensure product quality and safety; In power stations and other industries related to national economy and people’s livelihood, the components of equipment components shall be evaluated to ensure the safety of equipment.

Isolation switch contact is an important electronic and electrical device in high voltage distribution equipment. The silver-plated layer on the isolation switch contact has wear resistance and corrosion resistance, which can reduce the contact resistance. If the copper contact without silver plating is used, the resistance of the copper contact will increase significantly after oxidation, which will produce the possibility of arc ablation of the contact. The possibility of arc ablation can be greatly reduced by using copper – plated silver contact. Therefore, according to the requirements of “Relevant Regulations on Ordering High voltage isolation switch” of State Grid Company, the main contact of high voltage isolation switch shall have a silver plating thickness of no less than 20um, a general contact shall have a silver plating thickness of no less than 8um, and a hardness of no less than 120 Webster’s. The silver coating of the main contact of the high voltage isolation switch is also one of the important indicators of acceptance equipment.

High and low voltage power distribution cabinet

For electroplating manufacturers, the cost of electroplating silver is the amount of precious metal silver, so the thicker the coating, the higher the cost of electroplating manufacturers, so some bad electroplating manufacturers, the thickness of electroplating silver using shoddy, thin thick, seriously affected the acceptance of high-voltage power distribution equipment, even a part of the high-voltage power distribution equipment manufacturers by the State Grid again and again, If the product is reported to be defective again and again, it will be banned from the bidding qualification of the State Grid system for six months to two years, or be directly blacklisted by the State Grid bidding system.

At present, the measurement methods of silver layer thickness of isolation switch contact are mainly tested by handheld X-ray coating thickness analyzer and X-ray table coating thickness tester.

Isolation switch contact silver plating thickness measurement instrument, is a kind of X-ray spectrometer, through the X-ray on the silver layer after irradiation and then X-ray fluorescence, can analyze and detect the thickness of the switch contact silver plating instrument, the instrument is divided into two handheld and desktop, can quickly and non-destructive through irradiation tens of seconds can measure the thickness of the silver plating layer, Convenience and speed are important instruments for electric power equipment manufacturers and electroplating and surface treatment enterprises to test the coating thickness of products.

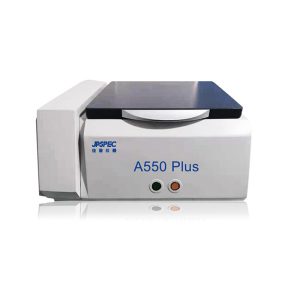

K-8000T coating thickness analyzer The handheld coating thickness analyzer is equipped with professional application software specifically for coating thickness analysis. It has the characteristics of intelligence, high sensitivity, short test time, automatic judgment whether exceeding the standard, easy operation, and can realize the function of measuring while playing. New intelligent software, one key intelligent operation detection of alloy composition and coating thickness;

K-8000T coating thickness analyzer alloy analyzer can also quickly detect and identify a variety of metal types, content and impurities; Can quickly detect and identify a variety of high and low alloy steel, stainless steel, tool steel, chromium/molybdenum steel, nickel alloy, cobalt alloy, nickel/cobalt heat resistant alloy, titanium alloy and other metals brand and element content; The instrument is pre-installed with multi-matrix standard vault, which includes more than 400 kinds of alloy grades. Users can also build their own alloy grade library.

K-8000T Handheld coating thickness analyzer,Elemental analyzer of metal composition

The functions are as follows:

(1) Intelligent identification of substrate type function: based on the rapid return on investment for users, improve productivity, automatic identification of substrate type, no manual selection of sample type, and then test; Reduce the difficulty of operation, save testing time, whether the operator is experienced or not, can obtain alloy and even aluminum alloy brand in seconds.

(2) Perfect alloy database: K series alloy analyzer is equipped with a perfect alloy database, the standard grade library includes more than 500 unique alloy grades, users can easily add customers unique elements and grades.

(3) Wide detection range: unmatched light element analysis function, Rapid and accurate analysis of conventional metal elements Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Zn, Se, Y, Zr, Nb, Mo, W, Ta, Hf, Re, Au, Pb, Bi, Ru, Pd, Ag, Cd, Sn, Sb, etc.

K-8000T Handheld coating thickness analyzer,Elemental analyzer of metal composition

Commodity parameter

K-8000T Handheld coating thickness analyzer,Elemental analyzer of metal composition

Instrument parameters:

1. Excitation source: high-power miniature straight plate electron X-ray tube, excitation voltage is 35kV; No high voltage cables, no RF noise, better X-ray shielding, better heat dissipation.

Fixed voltage 35kV, current 100uA (Moxtek), standard Ag target, no motor, 1 filter

2, detector: Si-pin detector (6 mm2 energy resolution 190eV FWHM)

3, calculation method: KMX-FP no standard sample test method

4, standard with 1 battery