- Description

- Inquiry

Description

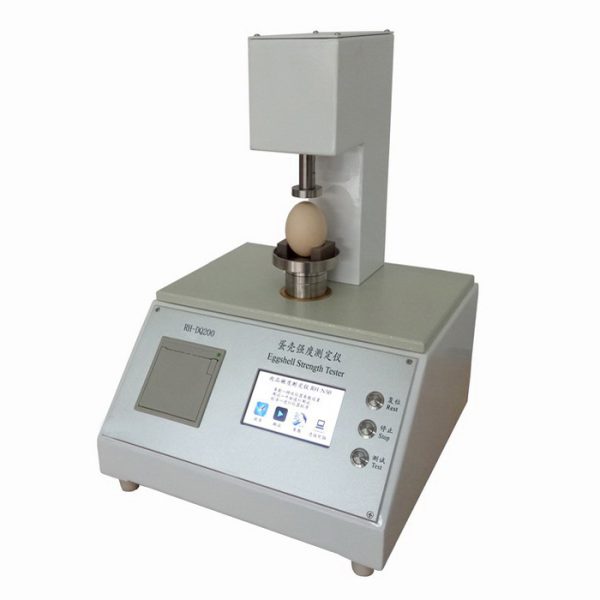

LR-DQ200 Eggshell Strength Tester

Product Introduction

LR-DQ200 Eggshell Strength Tester is an important indicator to measure the Eggshell quality of chickens, geese, ducks and other poultry eggs.The eggshell strength is closely related to the hatching rate, hatching rate, seedling quality and fresh egg yield of commercial laying hens.Hard shell eggs rarely break, can be a longer and intact preservation of their nutritional value, good commercial properties.Eggshell quality decline, the economic loss to many chicken farms is quite serious.The eggshell strength is closely related to breed, heredity and diet of breeders.It is particularly important to correctly grasp the relative indexes of eggshell strength.The eggshell strength tester developed and produced by our company is simple in operation, rapid and accurate in measurement, and provides direct data for egg quality analysis and livestock breeding. It is an ideal testing instrument for egg quality indicators in large chicken farms, food processing plants and scientific research institutes.

Principle: The egg is fixed and placed vertically between the upper and lower measuring surfaces. The measuring surfaces move relative to each other at a certain speed, and the egg is crushed.The force required by the egg crushing process is measured by a sensor, and recorded and displayed.

LR-DQ200 Eggshell Strength Tester

Main technical parameters:

| Measuring range | (0~200) N or (0~20) KGF |

| Resolution | 0.01N |

| Accuracy | <±1% |

| Test speed | (0.5~20)mm/s can be set arbitrarily |

| Dimensions | about 330mm×335mm×445mm |

| Weight | about 28kg |

| Voltage | 110~240V 50Hz |

LR-DQ200 Eggshell Strength Tester

Product features:

1, the use of American chip control, high precision force sensor, high precision.

- Adopt high-performance stepping motor and precision ball screw drive to ensure the precision of the instrument transmission.Aluminum alloy panel, reasonable design, ensure the instrument durable.

3, Large touch screen Chinese display, compression curve, friendly man-machine interface operation.Fully automatic completion of testing.Easy to operate, with test data statistical processing function, micro printer output.The standard RS232 interface facilitates the external connection and data transmission between the system and the computer

4, Equipped with egg shell erection fixing device randomly, convenient and quick measurement.

- The calibration procedure is specially set inside the instrument to facilitate the measurement and calibration department (third party) to calibrate the instrument.During calibration, enter the calibration test program and place the standard sensor between the upper and lower pressure plates to easily calibrate the error of the indicated value.

6, unit selection diversity, users can switch between unit N and kg according to need.