Small Manual Injection Machine For Test Sample

- Description

- Inquiry

Description

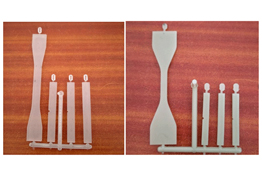

Small Manual Injection Machine For Test Sample

1. Equipment introduction

An injection molding machine is a mechanical device. It is usually composed of injection system, die closing system, pressure transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system and so on.

Injection system is one of the most important parts of injection molding machine, generally has plunger type, screw type, screw premolded plunger injection type three main forms. At present, the screw type is the most widely used. Its function is that in a cycle of the plastic injection machine, a certain amount of plastic can be heated and plasticized within a specified time, and the molten plastic can be injected into the mold cavity through the screw under a certain pressure and speed.

Small Manual Injection Machine For Test Sample

2.Product features

1, humanized workbench height design, suitable for large machine, comfortable operation, so as to reduce the labor intensity of the operator, improve work efficiency.

2. The injection molding machine adopts manual operation design to achieve the requirements of fast, simple and easy maintenance.

3. The movable parts of template and machine column are made of high rigid copper bushing to meet the requirements of smooth movement and long service life and high precision.

4, injection molding system adopts manual double guide column design, smooth movement, high injection accuracy.

5. Manual feeding is adopted.

6, table pliers mold installation, disassembly is convenient, can greatly improve the output and work efficiency.

7, mold adjustment alone side control, convenient from the Angle of view, humanized Angle to facilitate rapid exchange of molds.

8, humanized design of the launching platform lifting system, convenient, fast, time and manpower saving mold adjustment or mold change.

Two, electronic control function characteristics:

The temperature of injection molding furnace is controlled by digital temperature controller with high precision.

Small Manual Injection Machine For Test Sample

3. Equipment parameters

1, temperature range: RT ~ 300℃ (±3℃)

2, plunger diameter: 20mm

3. Maximum compression stroke: 135mm

4, heating cavity size: 20 * 70mm

5. Maximum injection volume: 20cm3 (20g)

6, the maximum size of the mold: 120 * 120 * 80mm

7, machine weight: 35kg

8. Power supply: 500W

9, voltage: 220V / 110V, 50/60Hz