VOCs Gas Chromatograph Solution

- Description

- Inquiry

Description

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Simple description of scheme

Instrument configuration: headspace + gas chromatograph + workstation software + nitrogen hydrogen air source

Approximate budget: The enterprise budget is tight, can be equipped with domestic gas chromatography, the approximate budget is about 80,000 yuan

The enterprise has sufficient budget, which can be equipped with Shimadzu or Agilent gas phase, and the budget is about 180,000 yuan

Sample making time: Make samples quickly, about 10 minutes for each sample

Operation and maintenance: low cost of late operation and maintenance

Cigarette packaging, ink, paint, printing industry VOCs gas chromatograph solutions

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Main characteristics of the instrument

1, the host comes with two valve parts control system, convenient to realize online automatic sampling.

2. The compensation circuit between columns makes the drift of the baseline during the program temperature rise operation be electronically compensated, reducing the complexity brought by the second column, detector and auxiliary flow system.

3, detector signals, heater values, heating furnace temperature, flow sensor readings or stored column compensation baseline signals can be distributed to a simulated output channel.

4, automatic detection and fault diagnosis, power protection stored experimental data, stopwatch and running timer, keyboard locking function.

5, can be connected to reverse control workstation, real-time control, and can store 100 sets of experimental conditions and spectra.

6, can install two flow sensing channels, two single column compensation channels.

* Heating furnace system

Temperature range: Ambient temperature +5 ° C to 400 ° C

Third order programmed heating rate of 0 ~ 50ºC/min; The increment is 0.1ºC/min. Temperature control accuracy ±0.015ºC,

The user can re-calibrate the furnace temperature and set the temperature at will.

Intelligent rear door opening system stepless variable inlet and outlet air volume, shorten the system stable balance time after rising/cooling. The time of column box dropping from 300ºC to 50ºC < 7 minutes.

* Sampling system

Capillary injector: Optional shunt/non-shunt injection system controlled by a programmed valve.

* detector system

Hydrogen flame ion detector (FID) :

Easy to disassemble and install, easy to clean or replace the nozzle, simple operation; Input signal can be logarithmic amplification, reduce interference, high sensitivity, good linearity, wide range.

Sensitivity: Mt≤5×10-12g/s(n-cetane)

Baseline noise: ≤ 6×10-12A/H

Linear range: ≥105

Stability time: < 0.5h

*LHDK-600 headspace sampler

The headspace sampler is connected with the gas chromatograph by a nine-core interface, and the parameters can be inserted by the main machine. After starting, complete the work of automatic heating, charging balance, quantitative tube sampling, six-way valve switching automatic sampling, starting workstation to start sampling and recording, etc.

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Set parameter range

Time: Sample heating, charging balance, injection 0 ~ 99min

Temperature: sample heating, quantitative tube and pipe insulation room temperature ~ 200ºC

Pressure: Carrier gas balance 0 ~ 0.25Mpa

Station: six stations heating.

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Range of instrumental analysis

The trace volatile organic compounds (VOC) of benzene, toluene, ethylbenzene, xylene (o, m, p), ethanol, isopropyl alcohol, n-butanol, acetone, 4-methyl-2-pentanone, butanone, cyclohexanone, ethyl acetate, n-propyl acetate, n-butyl acetate, isopropyl acetate and propylene glycol methyl ether in cigarette strips and box wrapping paper were analyzed.

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Analysis principles (* Compliant with tobacco industry standards YC/T207-2006 and YC263-2008)

In a closed container and at a certain temperature, the volatile components in the sample have a distribution balance between the gas phase (headspace) and the matrix (liquid or solid phase). When the equilibrium is reached, the gas phase is separated by gas chromatography. After matrix correction, the content of each volatile component in the sample can be determined, that is, headspace-gas chromatography (HS-GC).

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Analysis conditions

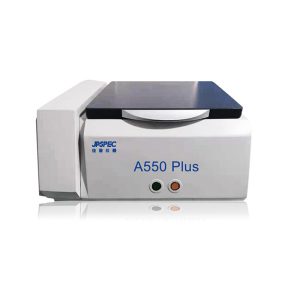

Chromatograph: Guangzhou Golden Valley scientific instrument set of top air chromatograph sampler temperature: 150ºC

Temperature of the detector: 250ºC column box temperature: 40 degrees for 2 minutes, 4 degrees to 180 degrees per minute, keep for 15 minutes. Column front pressure 0.06Mpa. Capillary column: 60m column imported from USA

VOCs Gas Chromatograph solution for Cigarette pack printing Food printing ink

Chromatogram of standard sample:

Shanghai Linghua gas Chromatograph