VU-2Y Impact sample notch broaching machine(hydraulic type)

- Description

- Inquiry

Description

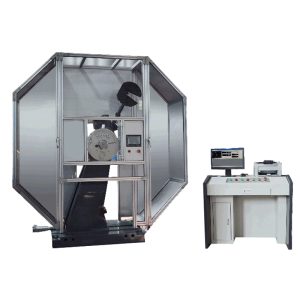

VU-2Y Impact sample notch broaching machine

Performance description:

In the material notch impact test, the processing of the v-notch (or u-notch) is the key question whether the test can be carried out. This broaching machine provides you with an ideal and absolutely guaranteed 100% dedicated equipment for the processing of qualified v-notch (or 2mm u-notch).This broaching machine is the newest product which has the leading level in China according to the actual demand of domestic users and the development experience of this field at home and abroad.

VU – 2 y broaching machine for oil pump hydraulic cylinder drive way, according to user requirements and configuration of V type or U broach, sample gap forming in one time and one time could be successfully drawn two standard sample gap, broach the use of special materials, special process precision processing and manufacturing, high hardness, good wear resistance, long service life and processing the v-notch and u-shaped notch (2 mm) can meet related national standards GB/T229-2007, due to a broaching processing forming principle, the processing of identity is wonderful, can guarantee the sample processing by the gap one hundred percent qualified.

VU-2Y Impact sample notch broaching machine

Main technical indicators

Notch type of processed sample: V type,U type (2mm)

Sample size: 10 x 10 x 55

Broaching speed: 2.0m/min

Broach stroke: 340 mm

Broach material: W18Cr4V

VU-2Y Impact sample notch broaching machine

Working principle:

Vu-2y impact test notch hydraulic broaching machine is composed of hydraulic part, main transmission part, electric control part and auxiliary part.

The hydraulic part is composed of oil tank, motor, pump, oil cylinder, etc. The main motor belt pump rotates clockwise to absorb oil, and the oil supply cylinder moves up and down to cut V type and U type notch at the speed of 2.0m/min.The cutter is provided with a lubricating cup, which is filled with lubricating oil (30# oil or other lubricating oil).Before and after cutting, dip the brush into a small amount of oil to remove the iron filings to lubricate the blade.There is an oil receiving box under the oil cylinder, and a small amount of lubricating oil flows down.It can be cleaned regularly according to the working time of the machine.