БГД 309 Ручна дигитална машина за тестирање чашице

- Опис

- Упит

Опис

БГД 309 Ручна дигитална машина за тестирање чашице

Опис

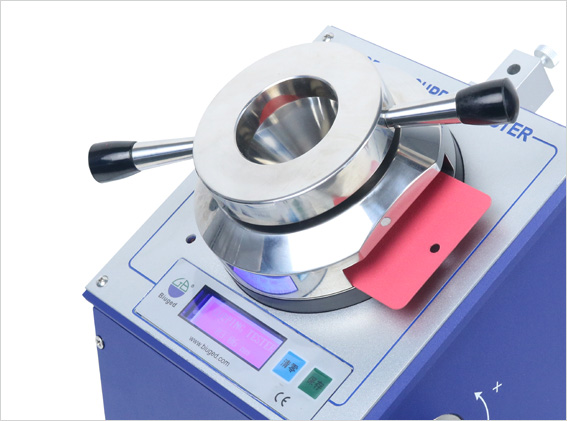

БГД 309 Cupping Tester is applicable to evaluate crack resistance and detachment from the metal substrate of coated surface which is coated with paint, varnish, итд., after the coating layer is deformed gradually under standard condition. The sample panel(max. 1.25mm thick×70 mm width, coated min.0.03mm)is clamped by an upper wheel and manually cupped by a ф20mm hemispherical indenter onto a ф27mm die by a drive wheel. The depth to cause failure is indicated on a precise digital display. The results can be easily observed with an illuminated magnifier

◆ Compliance with ISO 1520,BS 3900 Part 4,DIN 53166,DIN 53233 итд

◆ Automatic coordinate positioning system: tester can memorize the home position after being zeroed, also track the punch’s position automatically. Стога, the traditional error caused by return or shake can be avoided.

◆ Highly precise position sensor: the minimum division value of the depression depth can reach 0.01mm.

◆ Applicable for every kind of substrate, and the maximum pressure can reach 2500N.

◆ The coordinate position of the plug can be zeroed manually and can be memorized

◆ Come with 10X illuminated mangnifier, convenient to observe and judge test result.

◆ Hand twist operation: laborsaving and easy-handling.

БГД 309 Ручна дигитална машина за тестирање чашице

Параметерс

■ Diameter of punch: ф20mm

■ Maximum dent thickness: 12мм

■ Maximum depress power: 2,500Н

■ Resolution of dent: 0.1мм

■ Counter: дигитални екран, in 0.01mm increments

■ Dimension of test pane:150mm×70mm ×0.03-1.25mm (Smooth, not deformed)

■ Material:polished steel panel

■ Weight: 28KG

■ Overall Size: 290mm×240mm×370mm (L×W×H)

■ Ordering Information:BGD 309—Digital Cupping Tester