LR-A044 เครื่องฉีดขึ้นรูปแบบแนวตั้งขนาดเล็กแบบนิวแมติก

- คำอธิบาย

- สอบถามรายละเอียดเพิ่มเติม

คำอธิบาย

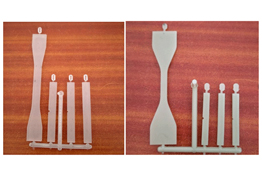

LR-A044 เครื่องฉีดขึ้นรูปแบบแนวตั้งขนาดเล็กแบบนิวแมติก

1.Equipment introduction

An injection molding machine is a mechanical device. It is usually composed of injection system, die closing system, pressure transmission system, electrical control system, lubrication system, heating and cooling system, safety monitoring system and so on.

Injection system is one of the most important parts of injection molding machine, generally has plunger type, screw type, screw premolded plunger injection type three main forms. ในปัจจุบัน, the screw type is the most widely used. Its function is that in a cycle of the plastic injection machine, a certain amount of plastic can be heated and plasticized within a specified time, and the molten plastic can be injected into the mold cavity through the screw under a certain pressure and speed.

LR-A044 เครื่องฉีดขึ้นรูปแบบแนวตั้งขนาดเล็กแบบนิวแมติก

2.ปผลิตภัณฑ์ เอฟรับประทานอาหาร

1, humanized workbench height design, suitable for large machine, comfortable operation, so as to reduce the labor intensity of the operator, improve work efficiency.

2.The injection molding machine adopts pneumatic operation design to achieve the requirements of fast, simple and easy maintenance.

3.The movable parts of template and machine column are made of high rigid copper bushing to meet the requirements of smooth movement and long service life and high precision.

4, injection molding system adopts pneumatic double guide column design, smooth movement, high injection accuracy.

5.Manual feeding is adopted.

6, table pliers mold installation, disassembly is convenient, can greatly improve the output and work efficiency.

7, mold adjustment alone side control, convenient from the Angle of view, humanized Angle to facilitate rapid exchange of molds.

8, humanized design of the launching platform lifting system, สะดวก, เร็ว, time and manpower saving mold adjustment or mold change.

LR-A044 เครื่องฉีดขึ้นรูปแบบแนวตั้งขนาดเล็กแบบนิวแมติก

ข้อกำหนดทางเทคนิค

| แบบอย่าง | LR-A044–20 | LR-A044–40 | LR-A044–60 |

| ช่วงอุณหภูมิ | RT〜450℃(±3℃)【Max limit 450degree】 | ||

| Plunger diameter【mm】 | 25มม | 35 | 45 |

| Max compression stroke【mm】 | 150มม | ||

| Heating cavity size【mm】 | 25 * 110 | 35 * 110 | 45 * 110 |

| Max injection capacity【mm】 | 20ก | 40ก | 60ก |

| Injection pressure | 1ต | 1ต | 2ต |

| Injection time | 0-9999s【can set】 | ||

| Cavity structure | Can be replaced is the mold cavity, effectively prevent material mutual pollution | ||

| Security and protection | Protective door + safety grating [Optional parts] | ||

| Maximum size for mold installation | 200 * 160 * 210 | 200 * 200 * 210 | 210 * 200 * 210 |

| Machine weight【kg】 | 35 | 55 | 65 |

| พลัง | 800ว | 1000ว | 1200ว |

| แรงดันไฟฟ้า | 220V/ 60HZ | ||

| แหล่งอากาศ | 0.6เมปา | ||

| Control Methods | นิวเมติก | ||

| ขนาดภายนอก(มม) | 550 * 600 * 1300 | 600 * 660 * 1400 | 650 * 660 * 1550 |