The neglected role of wire coater in wet film preparation in laboratory

In the laboratory, the preparation of wet film is the basis of coating inspection, however, many times, inspectors often neglect a crucial step, that is, the selection of the right line coater. The wire rod coater is a coating rod using the Mayer rod principle, which plays an integral role in the wet film preparation process and is essential for the control of sample film uniformity and film thickness. This paper will discuss the key role of wire coater in wet film preparation in the laboratory, and emphasize its importance in coating detection.

Wet film preparation is the basis of coating detection

Before coating testing, the first task is to prepare a wet film. Wet film refers to a thin, undried coating or coating material, and its uniformity and film thickness directly affect the accuracy and repeatability of subsequent detection. If the wet film is not prepared properly, it may lead to uneven coating, uneven film thickness or falling off, which can affect the test results.

The neglected role of wire coater in wet film preparation in laboratory

Understand the principle of wire coater

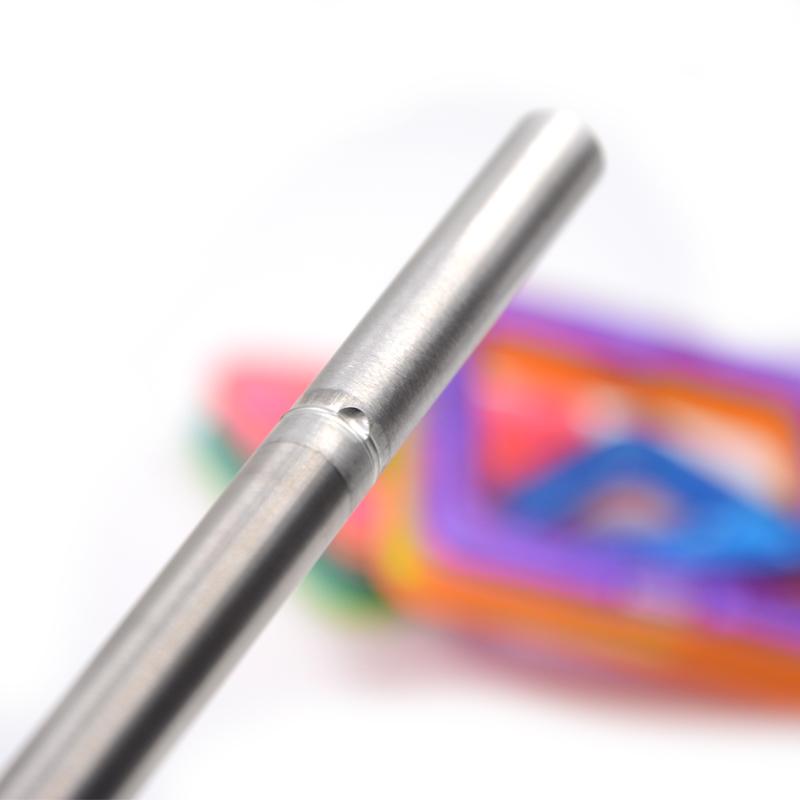

A wire rod coater is a film coating tool based on the Mayer rod principle. It works by pouring the paint or coating material into a container and then using a coating rod (line rod) to evenly apply the paint to the surface of the substrate. The surface of the coating rod usually has a uniformly distributed concave and convex texture, which helps to achieve uniform coating distribution and film thickness control. The selection of a suitable wire coater is essential for the preparation of a uniform and consistent wet film.

The wire and rod coater ensures that the paint or coating material is evenly distributed on the substrate. This helps to avoid spots, voids or uneven areas in the coating, thus ensuring the consistency of the test sample. The wire rod coater allows the user to precisely control the thickness of the wet film. By selecting the appropriate coating rod size and adjusting the coating speed, the desired film thickness can be achieved to ensure the accuracy of the test. The wire rod coater provides a high degree of repeatability for preparing wet films. This means that wet films of the same thickness and uniformity can be prepared at different points in time for multiple tests and comparative analysis.

The neglected role of wire coater in wet film preparation in laboratory

Select the appropriate wire coater

In order to ensure the accuracy and reliability of coating inspection, it is crucial to select the right line coater. Here are some factors to consider when choosing a wire rod coater:

Coating rod specifications need to consider the different process, width and groove depth of coating rods suitable for different film thickness requirements. Select the appropriate coating rod size according to the test requirements. The film thickness and uniformity of wet film can be affected by adjusting the coating speed when scraping film. Adjust according to the required preparation parameters. Ensure that the wire rod coater is compatible with the paint or coating material used, taking into account viscosity, fineness and corrosion issues to avoid material reactions or corrosion. Therefore, it is very important to choose a suitable wire coater to adapt to different test requirements and coating materials.

In coating inspection, wet film preparation is a crucial step, and the wire rod coater is a key tool to achieve uniform and consistent wet film. The correct selection and use of a rod coater helps ensure the accuracy and repeatability of the coating inspection, thereby increasing the confidence of the test results. Therefore, do not overlook the importance of the wire coater in the coating inspection, which is the basis for ensuring that the sample film is prepared evenly and the film thickness is correct.