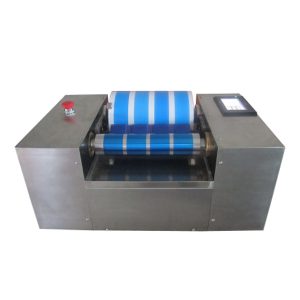

Flexo ink proofer(LED-UV online drying) UV Curing Machine

- опис

- Запит

опис

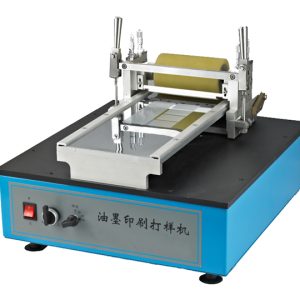

Flexo ink proofer(LED-UV online drying)UV Curing Machine/Flexo printing ink curing machine

Applicable objects: монохромна перевірка (наприклад підбір кольорів, тестування, тощо)

Вхідна потужність: 220В, 50/60HZ

потужність: 400В

Ink way: drip ink

Flexo ink proofer(LED-UV online drying)/UV Curing Machine/Flexo printing ink curing machine

Thickness of proofing material: 0.01-2мм (bendable material)

Proofing material size: 170x220mm

Printing area: 117x138mm

Plate area: 150x170mm

Товщина плити: USA Dupont 1.7mm thick flexible plate back glue 0.3mm

Pressure of plate roller and anilox roller: adjustable by ±2mm, with scale to show pressure

Plate roller and embossing pressure: adjustable by 2mm, with scale to show the pressure

Printing speed adjustable: 0-120 м/хв

Specification of ceramic roller:USA φ70x210mm

Lines number of ceramic roller: стандартний 600LPI (70-1200 lines can be customized) BCM:1.6-5.3

Застосовне чорнило: флексографічний водорозчинний, УФ-чорнило, літографія, рельєфна звичайна або УФ-чорнило

Suitable proofing materials: папір, plastic film, non – woven fabric, napkin, gold and silver paper jam, тощо

External dimensions (length x width x height) : 450x800x240mm

Вага нетто: 110КГ

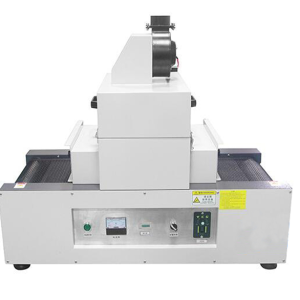

UV curing device selection

The instrument can be coated, суцільний колір, dot pattern proofing

Flexo ink proofer(LED-UV online drying)/UV Curing Machine/Flexo printing ink curing machine

Specification of Ceramic anilox roller

| BCM | 2.0 |

| Ink hole carving Angle | 60° |

| ink cavity shape | Regular hexagon openings |

| Anilox roller wire Angle | 45° |

| Number of anilox roller lines | 600LPI |

| anilox roller concentric to beat | within 0.01mm |

Flexo ink proofer(LED-UV online drying)/UV Curing Machine/Flexo printing ink curing machine

Unique features of the instrument:

1. After the ceramic roller rotates the ink evenly, the printing material and plate cylinder start up and rotate for one week to complete the proofing work. The ceramic roller and the printing material cylinder synchronize with the printing plate cylinder to ensure the quality of proofing.

2. The four structures of scraper, ceramic roller, plate roller and printing material roller can adjust the pressure separately and adjust flexibly.

3. Net roller, scraper disassembly and installation is simple and convenient

4. Large cylinder structure is adopted to install printing materials, easy to install printing plate and clean printing plate.