国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

介绍

国际标准化组织 (国际标准化组织) 是国家标准机构的全球联盟 (ISO成员机构). 国际标准的制定通常通过ISO技术委员会进行. 每个对已成立技术委员会的主题感兴趣的成员机构都有权在该委员会中派代表参加. 与 ISO 联络的国际政府和非政府组织也参与了这项工作. ISO 与国际电工委员会密切合作 (国际电工委员会) 关于电气标准化的所有问题.

国际标准是按照第 2 部分给出的规则起草的。 3 ISO/IEC 指令的.

技术委员会通过的国际标准草案将分发给各成员机构进行投票. 作为国际标准的出版至少需要获得批准 75% 成员机构数量.

请注意 ISO 这部分的一些元素 6603 可能是专利权的主题. ISO 不负责识别任何或所有此类专利.

国际标准ISO 6603-1 was developed by the Technical Committee ISO/TC61, 塑料, 小组委员会SC 2, 机械性能.

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

The second edition cancels and replaces the technically revised first edition (国际标准化组织 6603-1:1985).

国际标准化组织 6603 由以下部分组成, 在塑料总标题下 – 硬质塑料穿刺冲击性能的测定:

– 部分 1: 非仪器冲击试验

– 部分 2: 仪器化冲击测试

Appendix A of this part of ISO 6603 is for information purposes only.

1 范围

This standard specifies a method for determining, under specified conditions, the puncture impact properties of rigid plastics in the form of flat specimens, such as disks or squares. The sample can be molded directly, cut from the sheet or removed from the finished product. Different types of samples and test conditions are defined.

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

These drop dart methods are used to study the behavior of plastic films or molds under the impact of a firing pin perpendicular to the specimen plane.

ISO的这一部分 6603 can be used if it is sufficient to characterize the impact behavior of plastics by an impact failure energy threshold based on many samples. If a force-deflection or force-time plot recorded at a nominal constant firing pin speed is necessary to characterize impact behavior in detail, 国际标准化组织 6603-2 is used.

These test methods are suitable for specimens with thicknesses between 1 mm and 4 毫米.

Note For thicknesses less than 1 毫米, 国际标准化组织 7765 被推荐. If the equipment is suitable, it is possible to test thicknesses greater than 4 毫米, but this test falls outside the scope of ISO 6603-1 和ISO 6603-2.

These methods are suitable for the following types of materials:

Rigid thermoplastic molding and extrusion materials, including filled, unfilled and reinforced compounds and sheets;

– Rigid thermosetting molding and extrusion materials, 包括填充和增强化合物, sheets and laminates;

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

Fiber-reinforced thermoset and thermoplastic composites, including unidirectional or non-unidirectional reinforcement materials, such as MATS, 机织物, woven roving, cut strands, combined and mixed reinforcement materials, roving, milled fibers and sheets made from pre-impregnated materials (prepregs).

These methods are also applicable to samples molded or machined from finished products, laminates and extruded or cast plates.

The test results are comparable only when the preparation conditions, size and surface of the sample and the test conditions are the same. 尤其, the results determined on specimens of different thicknesses cannot be compared with each other (see Appendix E: – 符合ISO 6603-2). A comprehensive assessment of the impact stress response requires measurement of the impact velocity and temperature of different material variables, such as crystallinity and moisture content.

The impact behavior of the finished product cannot be predicted directly from this test, but samples can be taken from the finished product (see above) for testing by these methods.

Test data developed through these methods should not be used in design calculations. 然而, information on the typical behaviour of the material can be obtained by testing at different temperatures and impact velocities (see Annex D of ISO 6603-2: -), varying thickness (see Annex E of ISO 6603-2: -) and testing samples prepared under different conditions.

ISO的这一部分 6603 describes two statistical test methods:

– 方法A: Staircase Method (Individual) (preferred)

在这个方法中, a uniform energy increment is used during the test. After testing each sample, the energy is reduced or increased by uniform increments, depending on the observations (pass or fail) of the previous test.

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

– 方法B: Group method (选修的)

在这个方法中, a continuous group of at least ten samples is tested. The impact failure energy is calculated statistically.

2 规范性引用文件

下列规范性文件的规定:, 在此引用, 构成ISO本部分的规定 6603. 对于注明日期的参考文献, 这些出版物的任何后续修订或修正均不适用. 然而, 基于 ISO 本部分的协议各方 6603 鼓励研究应用下列规范性文件新版本的可能性. 对于未注明日期的参考文献, 所提及的标准制定文件的新版本适用. ISO 和 IEC 成员维护当前有效国际标准的登记册.

国际标准化组织 291:1997, 塑料. Adjust and test the standard atmosphere.

国际标准化组织 293:1986, 塑料. Compression forming sample of thermoplastic material.

国际标准化组织 294-3:1996, 塑料. 热塑性材料样品的注塑. 部分 3: Small board.

国际标准化组织 295:1991, 塑料. Compression molding of thermosetting material samples.

国际标准化组织 1268:19741), 塑料 – Preparation of glass fiber reinforced, resin bonded, low pressure laminates or panels for test purposes.

国际标准化组织 2818:1994, 塑料. The sample was prepared by machining.

国际标准化组织 7765-1:1988, plastic films and sheets. The impact resistance was determined by the free falling dart method. 部分 1: Staircase method.

国际标准化组织 7765-2:1994, plastic films and sheets. The impact resistance was determined by the free fall dart method. 部分 2: Instrumental puncture test.

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

3 术语和定义

就 ISO 本部分而言 6603, 以下术语和定义适用:

3.1 概述

3.1.1 Failure

Any visible breakage of the specimen surface

3.2 Failure standard terms

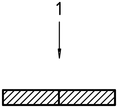

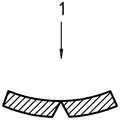

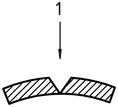

3.2.1 Crack

Any cracks that are visible to the naked eye and cannot penetrate the entire thickness of the material

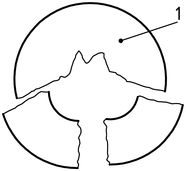

看: 数字 1

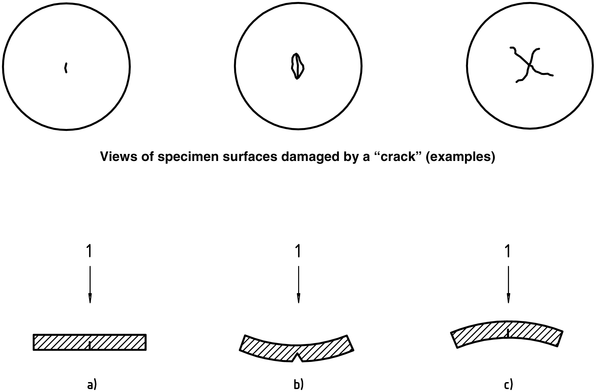

3.2.2 Broken

Any cracks throughout the entire thickness of the material

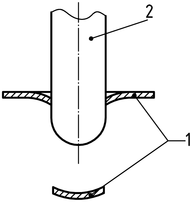

看: 数字 2

3.2.3 渗透

Failure of the firing pin to penetrate the entire thickness of the specimen

看: 数字 3 乙)

3.2.4 磨削

Break the sample into two or more pieces

看: 数字 3 A)

3.3 Impact failure items

3.3.150 % impact failure energy E50

The energy that causes 50% of the sample to fail, as defined in 3.1.1

3.3.250 % impact failure mass M50

The mass that causes 50% of the sample to fail at a given fall height, as defined in 3.1.1

3.3.350 % impact failure mass H50

50% impact failure height H50 uses the height at which a given falling mass causes 50% sample failure, as defined in 3.1.1

数字 1 – Specimen sections damaged by “裂缝” [乙) and c) after bending by hand

| 1 | Impact direction |

国际标准化组织 6603-1-2000 “塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 1: 非仪器冲击试验”

数字 2 – Slices passed through the specimen are damaged by “breakage” [乙) and c) after bending by hand

| A)

| 乙)

| C)

|

| 1 | Impact Direction |

数字 3 – Examples of “broken” failures [A) 和 “penetrated” [乙)

A)

乙)

| 1 | 标本 |

| 2 | Darts with hemispherical heads |

仅标准信息部分是公开的. 查看完整内容, 需要通过官方渠道购买标准.