国际标准化组织 6603-2-2000 “塑料硬塑料穿刺冲击行为测定 – 部分 2: 仪器冲击试验”

前言

国际标准化组织 (国际标准化组织) 是国家标准机构的全球联盟 (ISO成员机构). 国际标准的制定通常通过ISO技术委员会进行. 每个对已成立技术委员会的主题感兴趣的成员机构都有权在该委员会中派代表参加. 与 ISO 联络的国际政府和非政府组织也参与了这项工作. ISO 与国际电工委员会密切合作 (国际电工委员会) 关于电工标准化的所有问题.

国际标准是按照第 2 部分给出的规则起草的。 3 ISO/IEC 指令的.

技术委员会通过的国际标准草案将分发给成员机构进行投票. 作为国际标准的出版至少需要获得批准 75% 成员机构的数量.

Please note that some elements of this section of ISO 6603 May be the subject of patent rights. ISO 不负责识别任何或所有此类专利.

国际标准ISO 6603-2 由ISO/TC技术委员会制定 61, 塑料, 小组委员会SC 2, Mechanical Properties.

第二版取消并取代第一版 (国际标准化组织 6603-2:1989), which had been technically revised.

国际标准化组织 6603 consists of the following parts under the general heading Plastics – 硬质塑料穿刺冲击性能的测定:

— 部分 1: 非仪器冲击试验

— 部分 2: Instrumental impact testing

The appendices A to E of this part of ISO 6603 are for reference only.

国际标准化组织 6603-2-2000 “塑料硬塑料穿刺冲击行为测定 – 部分 2: 仪器冲击试验”

1 范围

ISO的这一部分 6603 specifies a test method for determining puncture impact properties of rigid plastics in the form of flat specimens using instruments that measure force and deflection. Applies if a force-deflection or force-time plot recorded at a nominal constant firing pin speed is necessary to characterize impact behavior in detail.

If ISO 6603-1 is sufficient to characterize the impact behavior of plastics by impact failure energy thresholds based on many samples, 国际标准化组织 6603-1 May be used.

ISO的这一部分 6603 is not intended to explain the mechanisms that occur at each particular point in the force-deflection diagram. These explanations are the task of scientific research.

Note also article 1 of ISO 6603-1:2000.

国际标准化组织 6603-2-2000 “塑料硬塑料穿刺冲击行为测定 – 部分 2: 仪器冲击试验”

2 规范性引用文件

The following normative documents contain provisions which, 在此引用, 构成ISO本部分的规定 6603. 对于注明日期的参考文献, no subsequent revisions or amendments to these publications will apply. 然而, Parties to an agreement based on this part of ISO 6603 are encouraged to investigate the possibility of applying the latest version of the following normative documents. 对于未注明日期的参考文献, the latest version of the normative document referred to applies. Members of ISO and IEC maintain a register of international standards currently in force.

国际标准化组织 2602:1980, Statistical interpretation of test results – mean Estimators – confidence intervals.

国际标准化组织 6603-1:2000, 塑料. Determination of puncture impact behavior of rigid plastics. 部分 1: Non-instrumental impact tests.

3 术语和定义

For the purposes of this part of ISO 6603, 以下术语和定义适用.

3.1 Impact velocity

The speed of the firing pin relative to the support at impact

笔记 1: The impact velocity is expressed in meters per second (多发性硬化症).

3.2 Force F

The force exerted by the firing pin on the specimen in the direction of impact

笔记 1: Force is expressed in Newtons (氮).

3.3 Deflection l

The relative displacement between the firing pin and the specimen support starts from the first contact between the firing pin and the specimen

笔记 1: Deflection is expressed in millimeters (毫米).

3.4 Energy

Energy used to deform and penetrate the specimen up to the deflection L

笔记 1: Energy is expressed in joules (J).

笔记 2 The energy is measured as the integral of the force-deflection curve from the point of impact to the deflection l.

国际标准化组织 6603-2-2000 “塑料硬塑料穿刺冲击行为测定 – 部分 2: 仪器冲击试验”

3.5 Maximum power FM

The most power that occurs during the test

笔记 1: The maximum force is expressed in Newtons (氮).

3.6 Deflection lm at maximum force

Deflection at maximum force FM

笔记 1 Deflection at maximum force is expressed in millimeters (毫米).

3.7 Energy to maximum strength

The energy expended at maximum force reaches deflection lM

笔记 1: The most powerful energy is expressed in joules (J).

3.8 Puncture deflection lP

The force is reduced to half the deflection of the maximum force F M

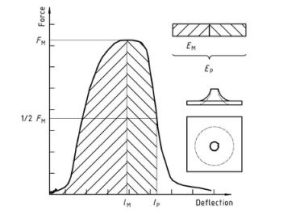

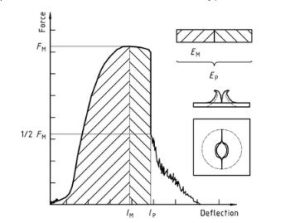

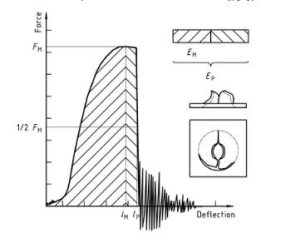

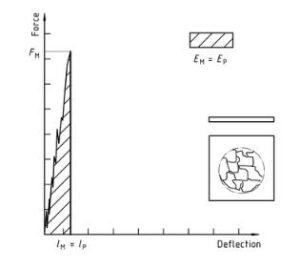

See Figures 1-4 和 3.9 notes.

笔记 1 Puncture deflection is expressed in millimeters (毫米).

3.9 Puncture energy

Energy expended until the puncture deflects lP

See Figures 1 through 4 and note 2.

笔记 1: Puncture energy is expressed in joules (J).

笔记 2 A probe mounted at a distance from the impact tip records the friction force acting between the cylindrical part of the firing pin and the piercing material when testing hard materials. The corresponding friction energy should not be included in the piercing energy, so the piercing energy is limited to that deflection, where the force drops to half of the maximum force FM.

国际标准化组织 6603-2-2000 “塑料硬塑料穿刺冲击行为测定 – 部分 2: 仪器冲击试验”

3.10 Impact Failure

Mechanical properties of the material to be measured, which may be of one of the following types (看注释) :

A) YD yIELDING (zero slope at maximum power), then DEEP yielding

乙) YS yIELDING (Zero slope at maximum power) 然后 (at least partially) cracked the S bench

C) yIELDING of Yu (zero slope at maximum power) Then u unstable cracking

d) no yielding for new features

笔记 1: A comparison of Figures 2 和 3 shows that puncture deflections l, P and puncture energy EP are the same for failure types YS and YU. As shown in Figure 4, in the case of failure type YU, the deflection and energy values are the same at maximum and puncture. For complex behaviour, 见附件A.

数字 1 — An example of a force-deflection diagram of the typical appearance of a specimen after deep drawing and testing (using lubrication) through yield (zero slope at maximum force)

塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 2: Instrument impact test Diagram 1

数字 2 — Example force-deflection plot of failure by yield (zero slope at maximum force), followed by steady crack growth, and typical appearance of the specimen after testing (using lubrication)

塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 2: Instrument impact test diagram 2

数字 3 — Examples of force-deflection plots through yield (zero slope at maximum force) and typical appearance (lubrication) failure of a tested specimen

塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 2: Instrument impact test diagram 3

Note that the natural vibration of the force detector can be seen after the unstable cracking (firing pin and weighing sensor).

数字 4 — An example force-deflection diagram of an unyielding failure followed by unstable crack growth and a typical appearance of the specimen after testing (using lubrication)

塑料 – 硬质塑料穿刺冲击性能的测定 – 部分 2: Instrument impact test diagram 4

仅标准信息部分是公开的. 查看完整内容, 需要通过官方渠道购买标准.