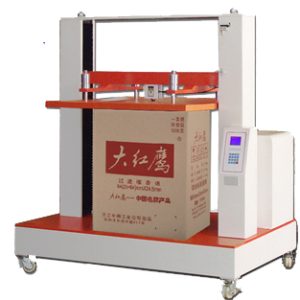

LR-189 Sponge collapsible hardness tester

- 描述

- 询问

描述

Sponge collapsible hardness tester

概括:

Foam Indentation Hardness Compression IFD Tester is used to test material compressed indentation hardness, such as sponge, foam and other porous elastic. Put specimen under pressure plate, the plate compress the specimen with a specify speed until the national standard require concavity, the load cell feedback the pressure to micro computer, it processing and display, then measure the indentation hardness of sponge, foam and other materials.

Applicable Testing Standards

国际标准化组织 2439: Flexible cellular polymeric materials — Determination of hardness (indentation technique) 国际标准化组织 3386-1: Polymeric materials, cellular flexible — Determination of stress-strain characteristic in compression ASTM D3574: Standard Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams 从 53576, JIS K6400-6 ETC… |

Sponge collapsible hardness tester

Speficiations:

Control and display | Touch Screen |

传感器 | USA “TRANSCELL” Load cell |

容量 | 100, 200 公斤 (or specified) |

单元 | G, 公斤, 氮, LB can be exchanged |

Accurate Grade | 1 年级 |

Up plate | 直径200毫米, bottom fillet R1mm (or customized) |

Low plate | 420×420mm, holes diameter 6mm, space 20mm (or customized) |

Max stroke | 200毫米 |

测试速度 | 100 ± 20mm/min (0.01~500mm/min adjustable) |

发动机 | Convertor Motor |

Driver | Taiwan high precision ball screw |

力量 | 交流220V, 50/60赫兹 (custom-made) |

Sponge collapsible hardness tester

特征:

1. Automatic return: after the sample breaks, it automatically returns to the original position.

2. Automatic shift: according to the size of the load, you can switch different gears to ensure the measurement accuracy;

3. Change the speed: the machine can change the test speed arbitrarily according to different samples;

4. Control method: test methods such as test force, test speed, displacement and strain can be selected according to test requirements.

5. Multi-purpose machine: support equip with different specifications of sensors, can achieve multi-purpose machine;

6. 展示: dynamic display of data and curve test process;

7. Limit: with program control and mechanical limit;

8. Overload: automatic shutdown when load exceeds rated value;