- وصف

- سؤال

وصف

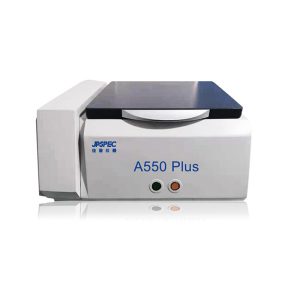

سميك 880 coating detector nondestructive illumination tester Coating thickness gauge

مجال التطبيق

1.Electroplating plant

2.Electronic appliance factory

3.Steel works/alloy works

4.مكتب الجودة والإشراف الفني

5.Automobile manufacturing

6.Test center

سميك 880 coating detector nondestructive illumination tester Coating thickness gauge

المزايا والخصائص

1.Ultra-high resolution, ultra-clear camera, ultra-convenient operation, ultra-fast detection speed, ultra-user-friendly interface

2.Easy-to-use, one-click analysis of carat grades and components

3.Innovative features that help identify the composition of the coating

4.Compact body structure, مظهر جميل, suitable for placement in the exhibition room

5.Accurate results on sample coating thickness can be obtained within seconds of pressing the button

6.Using PC and software, you can quickly and easily make the inspection result certificate of the sample

7.Users can see the test location of the sample through the camera and the cabin lighting system, which enhances their confidence in testing

8.Thick Series analyzer test data can be downloaded and uploaded to the network, ومن السهل عرض نتائج الاختبار ومشاركتها

9.X-ray protection lock, only in the closed state of X-ray emission, safe and reliable to ensure customer use

سميك 880 coating detector nondestructive illumination tester Coating thickness gauge

Instrument performance

1. أي عدد من نماذج التحليل وتحديد الهوية البديلة

2. Multivariable nonlinear recycling program

3. نموذج تصحيح تأثير المصفوفة المستقلة

4. Long-term working stability can reach 0.1%

5. Built-in high-definition camera

6. It can analyze more than dozens of elements and five layers of coating at the same time

7. Repeatability of multiple measurements can reach 0.1%

8. The coating thickness is generally within 50um (each material is different)

Electroplating thick layer detection

سميك 880 coating detector nondestructive illumination tester Coating thickness gauge

Electroplating process is to use the principle of electrolysis to lay a layer of metal on the conductive body to form a coating.

The performance of the coating is different from that of the substrate metal, and it has new characteristics to enhance the corrosion resistance of the metal (coated metal is mostly made of corrosion-resistant metal), increase hardness, prevent abrasion, improve the conductivity, سلس, heat resistance and surface appearance

According to the type of coating and the application of different products, there are also strict requirements for the thickness of the coating, which needs to be strictly controlled

X-ray method is suitable for determining the thickness of metal covering layer which needs to be analyzed in electroplating, electronic circuit board and other industries. Including: ذهب (الاتحاد الأفريقي) فضة (اي جي), القصدير (سن), نحاس (النحاس), النيكل (في), الكروم (سجل تجاري) and other metal element thickness.

This measurement method can simultaneously measure the thickness of multilayer metal coating