Chlorinated rubber anticorrosive coatings: Stability and wide application

Introduction:

Chlorinated rubber anticorrosive coating is a kind of coating with good stability and corrosion resistance, which is widely used in the coating of anticorrosive equipment. In this paper, the properties and preparation methods of chlorinated rubber anticorrosive coatings and their wide application in chemical industry, metallurgy, oilfield and other fields are introduced in detail.

Characteristics of chlorinated rubber:

Chloro-sulfonated polyethylene rubber is a special rubber material, which has no unsaturated bond in the molecular chain, large molecular weight, full degree of amorphous, and contains an appropriate amount of chlorine atoms, sulfur atoms and chlorosulfonyl groups. These characteristics give it the following good performance:

Stability: Because there are no saturated bonds in the molecular chain of chlorosulfonated polyethylene rubber, it has excellent stability and is not easily affected by chemical reactions.

Corrosion resistance: Chlorinated rubber anticorrosive paint contains chlorine atoms and sulfur atoms, these elements give it excellent corrosion resistance, can effectively protect the coated surface from corrosion.

Chlorinated rubber anticorrosive coatings: Stability and wide application

Preparation method:

The preparation method of chlorinated rubber anticorrosive coatings includes the following key steps:

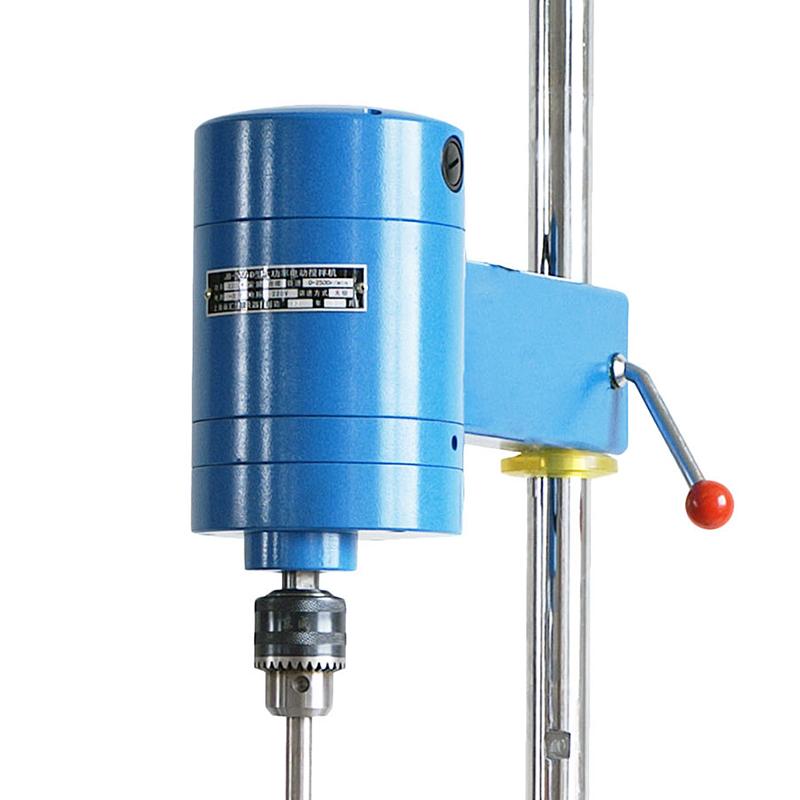

Plasticized rubber: First, butyl rubber and chlorosulfonated polyethylene are plasticized on the open mill to make them fully mixed.

Adding additives: In the plasticizing process, magnesium oxide, antioxidants and promoters are added to ensure uniform mixing.

Dissolve: the uniformly mixed rubber is sliced into part of the solvent and chlorinated rubber for dissolution, and then ground through the ink roller.

Final mixing: Finally, the remaining solvent is added to the mixture and after full stirring, a uniform paint is obtained.

Chlorinated rubber anticorrosive coatings: Stability and wide application

Scope of application:

Chlorinated rubber anticorrosive coatings perform well in a number of application areas, and the following is a brief introduction to their main application areas:

Sewer and drainage pipe surface anti-corrosion treatment: Because the coating has good flexibility, impact resistance, cold resistance, heat resistance and excellent sealing performance after cold and hot circulation, it is widely used in the sewer and drainage pipe internal anti-corrosion treatment to ensure long-term reliable operation of the pipeline.

Chemical industry: chlorinated rubber anticorrosive coatings are widely used in the coating of chemical equipment, which can effectively protect equipment from chemical corrosion damage.

Metallurgical industry: In the metallurgical sector, this coating can be used to coat metallurgical equipment, providing corrosion resistance and extending the service life of the equipment.

Oilfield equipment: Oilfield equipment is often eroded by harsh environments and chemicals, and the application of chlorinated rubber anticorrosive coatings in this field can effectively protect equipment and ensure the smooth operation of oilfield.

In SUMMARY:

Chlorinated rubber anticorrosive coatings are widely used in many industrial fields because of their good stability and corrosion resistance. With careful preparation, the coatings provide excellent coating protection, extend the service life of equipment and structures, and reduce maintenance costs. In the future, with the continuous improvement of the performance requirements for anti-corrosion coatings, chlorinated rubber anti-corrosion coatings will continue to play an important role in the industrial field, providing reliable protection for various equipment and pipelines.