Coating mechanical properties test: hardness VS scratch resistance

As an important protective material, the coating film not only needs to be beautiful and durable in appearance, but also needs to have certain mechanical properties to resist the physical effects of external factors on its surface. The evaluation of the mechanical properties of the film is very important to ensure the quality and performance of the film. This paper will discuss the testing of mechanical properties of coatings, with special attention to hardness and scratch resistance, as well as test methods and application fields.

Hardness – mechanical stability of the film

Hardness is the ability of the coating to resist various mechanical actions, usually expressed as the resistance of the coating surface to another harder object. The hardness test can help to evaluate the mechanical properties of the film, such as anti-collision, anti-crushing and anti-scratching. Different hardness testing methods can be used to characterize the hardness of the film from different angles.

Coating mechanical properties test: hardness VS scratch resistance

1. Pendulum rod damping hardness method

Pendulum rod damping hardness method is one of the commonly used hardness testing methods. Its principle is to apply a load through a steel ball on a suspended pendulum rod, so that it contacts the coating template. When the pendulum rod begins to swing, the film will produce resistance, and the hardness of the film is assessed according to the cycle time of the pendulum rod swing. The specific operation is to put the test template on the horizontal work table with the film facing up, and then make the pendulum rod slowly fall to the test board, and determine the time required for the pendulum rod to swing from a certain Angle to another Angle. A longer swing time indicates a higher coating hardness.

2. Scratch hardness method

Scratch hardness is another commonly used hardness test method that assesses the hardness of the film by applying a scratch load to the surface of the film. In this test, a standard scratching tool, such as a pencil hardness tester or a steel tip with a different hardness, is usually used to run across the coated surface. Hardness is assessed based on the depth and shape of the scratch.

Coating mechanical properties test: hardness VS scratch resistance

3. Indentation hardness method

Indentation hardness is another method of film hardness testing, which assesses hardness by applying a uniform pressure load to the surface of the film. In this test, a spherical indenter or diamond indenter is generally used to form an indentation on the surface of the film at a certain pressure. The evaluation of hardness is based on the diameter and depth of the indentation.

Choosing the appropriate hardness test method depends on the specific application and requirements of the coating. For example, for automotive coatings, scratch and crash resistance is a key performance requirement, so scratch hardness and pendulum rod damping hardness testing may be more applicable. In the film industry, hardness testing helps to evaluate the mechanical stability of the film, ensuring that it will maintain good performance during use.

Scratch resistance – protects the surface from damage

Scratch resistance is a key aspect of the mechanical properties of the film, which involves the resistance of the film surface to mechanical effects such as scratching and scraping. In real life, coatings often face a variety of scraping and scratching threats, so assessing scratch resistance is essential to ensure the durability of the coating.

Coating mechanical properties test: hardness VS scratch resistance

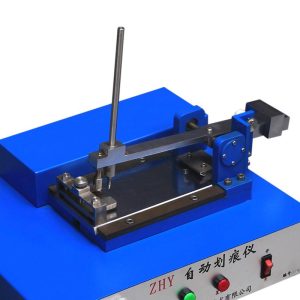

Scratch resistance is often evaluated using different test methods, the most common of which is the scratch test. Scratch testing can simulate scratches and scratches in real use to evaluate the scratch resistance of the film. In scratch testing, a standard scratching tool, such as an instrument with a hardness needle, is usually used to apply a certain load and motion to simulate the scratching and scratching action. Based on the results of the test, the scratch resistance of the coating can be evaluated and its performance under different scratch conditions can be determined.

Scratch resistance testing is of great significance for various coating applications. For example, in the automotive industry, body coatings need to have excellent scratch resistance to maintain the long-term appearance of the vehicle. In home decoration, the coating on the surface of the furniture needs to resist scratching and rubbing to protect the appearance of the furniture. Therefore, the scratch resistance test is an important tool to ensure that the film can maintain good performance in actual use.

Coating mechanical properties test: hardness VS scratch resistance

The mechanical properties of the film include hardness and scratch resistance, which are critical to the quality and durability of the film. Hardness testing can help assess the mechanical stability of the film, while scratch resistance testing can assess its resistance to wear in actual use. Choosing the appropriate test method depends on the application area and requirements of the coating, ensuring that the coating can maintain its performance in different environments. The evaluation of the mechanical properties of the coating will help to improve the quality of the coating, extend its service life and ensure its excellent performance in a variety of applications.