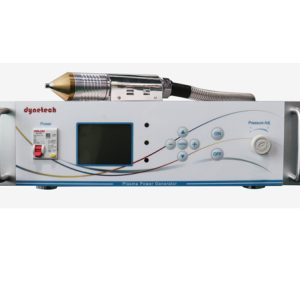

LRGD-10 Maliit na Vacuum Plasma Cleaner

- Paglalarawan

- Pagtatanong

Paglalarawan

Parameter ng produkto

| Pangalan ng produkto | Vacuum plasma cleaner |

| Modelo ng produkto | GD-10 |

| Suplay ng kuryente | AC220V(±10V) |

| Suplay ng kuryente | 100w-300w |

| Sukat ng lukab (mm) | 560X550X400mm(WXDXH) |

| Dalas ng pagpapatakbo | 40 KHZ and 13.56 MHz (Opsyon) |

| Presyon ng pinagmulan ng hangin | 2-2.5 kg |

| bigat ng katawan | 100kg |

| Gumamit ng gas | Nitrogen, oxygen, nitrogen, hangin |

| Haba ng koneksyon | 2m-4m |

Small vacuum plasma cleaner,Etcher for electronic products,Vacuum plasma surface treatment machine

Functional characteristics

Pagbabagong anyo ng ibabaw ng produkto

Ang pagbabago ng mga kagamitan sa plasma ng Fangrui ay maaaring epektibong mabawasan ang mga kadahilanan ng impluwensya ng materyal na pretreatment sa pamamagitan ng 95%

Pag activate ng ibabaw ng produkto

Ang rate ng pag activate ng ibabaw ng mga materyales na pretreated na may Fangrui plasma equipment ay 98%

Paglilinis ng ibabaw ng produkto

Ang pagbabago ng mga kagamitan sa plasma ng Fangrui ay maaaring epektibong mabawasan ang mga kadahilanan ng impluwensya ng materyal na pretreatment sa pamamagitan ng 95%

Bonding sa ibabaw ng produkto

Ang pagdikit ng materyal na ibabaw ay pinabuting ng 92% sa pamamagitan ng paggamit ng Fangrui plasma equipment

Application of multiple industries

Suitable for 95% industry, strong compatibility

Industriya ng pagmamanupaktura ng sasakyan

Industriya ng pagmamanupaktura ng mobile phone

Industriya ng pag print at pagtitina ng tela

Industriya ng packaging ng semiconductor

Mabigat na industriya

Bagong industriya ng enerhiya

Patlang ng FBC / PCB

Industriya ng medisina

Small vacuum plasma cleaner,Etcher for electronic products,Vacuum plasma surface treatment machine

Una, the advantages of vacuum equiseparation cleaning machine

Compared with traditional processes, plasma surface treatment technology has the following advantages:

[Strong function] : Modification only occurs on the surface of the material (about a few to dozens of nanometers), without changing the inherent properties of the matrix

To give one or more new functions;

[Wide application] : regardless of the substrate type of the treatment object, such as metal, plastik na plastik, salamin, polymer materials, atbp., can be processed;

[Easy to operate] : simple process, madaling mapatakbo, strong production control and high stability;

[Mataas na kahusayan] : short treatment time, high reaction rate, good treatment uniformity;

[Energy saving, pangangalaga sa kapaligiran] : The whole process of dry treatment, no consumption of water resources, no need to add chemical agents, no pollution.

Two, product introduction

RD-10 Vacuum plasma cleaning machine is a vacuum reaction chamber can rotate 360° cleaning machine, widely used in small batch production of enterprises or universities for scientific research. The whole machine is compact, matatag na pagganap, uniform and stable treatment effect, high cost performance, vacuum reaction chamber can rotate 360°, 360° without dead Angle processing granular products and small irregular products.

1. Equipment composition

Plasma cleaning machine is composed of reaction chamber (also known as vacuum chamber), vacuum system, discharge system, electric control system, intake flow control system.

The reaction chamber consists of a vacuum chamber and an electrode, which is a plasma reaction space. The items to be treated are placed in the reaction chamber. The vacuum system consists of a vacuum gauge, a vacuum pump and a vacuum pipe, which is responsible for purifying the air in the reaction chamber and maintaining an appropriate vacuum degree during operation. The discharge system provides signal and energy for the reaction chamber to stimulate the ionization of the reaction gas in the chamber to form the plasma needed. The function of the electronic control system is to control the operation process of the equipment according to the optimal process parameters and steps, and maintain the stability of the process parameters; The intake flow control system is mainly composed of mass flowmeters and electromagnetic valves. Its function is to accurately control the intake flow of the reaction gas and maintain the vacuum required during the working period.

The device uses a touch screen +PLC programmable controller, processing parameters can be arbitrarily set on the touch screen, with manual/automatic switching function. The automatic operation adopts “one key type”, and the working process is completely controlled by the computer automatically. Manual operation is performed by the user on the manual mode interface.

Small vacuum plasma cleaner,Etcher for electronic products,Vacuum plasma surface treatment machine

| bilang | Item type | Specific parameter |

| 1 | Plasma generator | Intermediate frequency 40Khz Intermediate frequency power 100~300W |

| 2 | Plasma reaction control software | Fang Rui technology independently developed proprietary software V1.0 Fully automatic system control |

| 3 | Vacuum chamber | Cavity internal size: Φ210*300mm Chamber material: 304 stainless steel material |

| 4 | Vacuum reaction chamber | Cavity internal size: Φ160*230mm Chamber material: 304 stainless steel material |

| 5 | electrode | Design of cylindrical electrode structure. Reaction volume: 5L |

| 6 | Vacuum pump | Bipolar direct rotary vane vacuum pump pumping rate: 14.4m3/H Limit vacuum: 6*10-2Pa Power: 0.55KW |

| 7 | Pipes and components | Vacuum pipe: 304 stainless steel vacuum corrugated pipe Working gas pipeline components: PVC transparent hose +304 stainless steel connectors to ensure efficient operation and reliability of the equipment. |

| 8 | Vacuum gauge | Japanese Panasonic digital display table |

| 9 | Gas control | 2 way process gas, solenoid valve control, mechanical manual adjustment 0.1 ~ 1NL/min |

| 10 | Plasma process gas | Support two process gas: argon, oxygen (argon, oxygen, nitrogen, hydrogen, carbon tetrafluoride optional) |

| 11 | Mode ng kontrol | 4.3 “industrial control touch screen, real-time display of working status |

| 12 | Vacuuming time | 30s pressure <50Pa |

| 13 | Vacuum breaking system | Solenoid valve + silencer Vacuum breaking time: 30s |

| 14 | Single processing time | 1-30 mga minuto (depending on product characteristics, power and time Settings are different) |

| 15 | Electrode material | Custom 304 stainless steel electrodes |

| 16 | Iba pang mga parameter | Suplay ng kuryente: AC220V(±10V) Laki ng makina: W700×D640×H475mm (for reference) Machine timbang: 55kg Machine: High – quality anti – rust paint |

| 17 | Motor speed range | <10 turns /min |