ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

perkenalan

ISO (Organisasi Internasional untuk Standardisasi) adalah federasi global badan standar nasional (badan anggota ISO). Pengembangan standar internasional biasanya dilakukan melalui komite teknis ISO. Setiap kelompok anggota yang tertarik pada suatu mata pelajaran yang telah dibentuk komite teknisnya berhak untuk diwakili dalam Komite. Organisasi internasional, pemerintah dan organisasi non-pemerintah yang berhubungan dengan ISO juga terlibat dalam pekerjaan ini. ISO bekerja sama dengan Komisi Elektroteknik Internasional (IEC) tentang segala hal standardisasi kelistrikan.

Bagian 1 Petunjuk ISO/IEC menjelaskan prosedur yang digunakan untuk mengembangkan dokumen ini dan untuk pemeliharaan lebih lanjut. Secara khusus, perhatian harus diberikan pada kriteria persetujuan berbeda yang diperlukan untuk berbagai jenis dokumen ISO. Dokumen ini telah disusun sesuai dengan aturan editorial Bagian Petunjuk ISO/IEC 2 (lihat iso.org/directives).

Harap dicatat bahwa beberapa elemen dari dokumen ini mungkin memiliki hak paten. ISO tidak bertanggung jawab untuk mengidentifikasi salah satu atau semua paten tersebut. Rincian hak paten apa pun yang diidentifikasi selama pengembangan dokumen dapat ditemukan dalam pendahuluan dan/atau daftar deklarasi Paten ISO yang diterima (lihat iso.org/patents).

Nama dagang apa pun yang digunakan dalam dokumen ini disediakan sebagai informasi untuk kenyamanan pengguna dan bukan merupakan dukungan.

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

Interpretasi sukarela, related standards and conformity assessment related ISO specific terminology and express the meaning of and the ISO in the technical barriers to trade (TBT) adhere to the principle of the world trade organization (WTO) information, please see the iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 35, Cat dan Pernis, Subkomite SC 9, Metode Uji Umum untuk cat dan pernis.

Daftar semua bagian dalam ISO 22553 seri dapat ditemukan di situs web ISO.

Any feedback or questions on this document should be referred to the user’s national standards body. A complete list of these institutions can be found at iso.org/members.html.

memperkenalkan

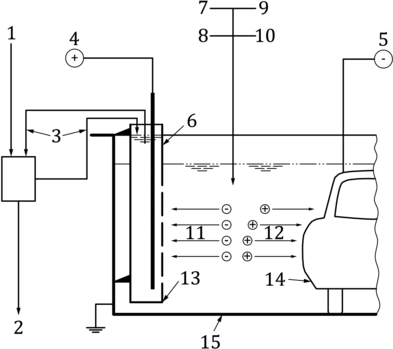

In the electrodeposition coating process, the non-volatile substances in the water-dilutive electrodeposition coating are deposited on the workpiece by the electrophoretic process. During this process, the internal and external areas of the workpiece, including all cavities, are touched. Cathode deposition or anode deposition is distinguished according to whether the workpiece is used as cathode or anode. The cathodic electrodeposition coating process is commonly used (lihat Gambar 1).

Angka 1 – Example of the deposition process during cathodic electrodeposition coating

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

Key

| 1个 | Softening water | 9 | solvent |

| 2个 | Wastewater treatment | 10 | Softened water |

| 3个 | Anodic fluid cycle | 11 | acid |

| 4个 | Anode | 12 | Electrodeposition coating |

| 5个 | Cathode | 13 | Ion selective membrane |

| 6个 | Anode box | 14 | body |

| 7 | Binder | 15 | Cathodic electrophoresis cell |

| 8个 | pigmen |

Through the combination of adhesives, pigments and deposition processes, hardening creates a very corrosion-resistant coating on the workpiece, which contributes significantly to corrosion protection in both internal and external areas.

The electrical properties of the material are also important for the electrical energy consumption (bulk charge density) of the process.

Since the electrophoretic paint is jointly responsible for the overall appearance of the coating system, it is often emphasized that the coating works well and has no visible defects.

Karena itu, for extensive corrosion protection and sealing of the workpiece, additional joint sealing materials, adhesives or foams are recommended.

Inside the electrophoresis tank, bacterial contamination may be present due to the material being dragged in and the physical conditions (panas, water-based media, carbon sources, dll.).

This document specifies the terms and definitions of electrodeposited coatings. The subsequent part of the ISO 22553 series specifies methods of characterization and testing of electrodeposited coatings. An overview of the test methods is given in Annex A.

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

1 Lingkup aplikasi

This document defines the terms for electrodeposited coatings.

It is suitable for electrodeposition coatings in the automotive industry and other general industrial applications, such as chiller, consumer goods, radiators, luar angkasa, pertanian.

2 Dokumen referensi normatif

There are no normative references in this document.

3 Istilah dan definisi

3.1 Volume charge density ρ

Quotient of charge Q and volume V, as shown in the formula:

Cat dan pernis – electrodeposited coatings – Bagian 1: Glossary Diagram 2

Catatan 1: The volume charge density is expressed in coulombs per cubic meter (C/m 3).

Catatan Artikel 2:1 C/m 3 = 1 A⋅s/m 3.

3.2 Deposition voltage u

The voltage is adjusted on the corresponding device to deposit an electrodeposited coating material (3.9) by an anode or cathode method, having a film thickness specified for the coating material

Catatan 1: The deposition voltage is measured in volts (V).

3.3 Deposition time

The time required to obtain the desired film thickness

3.4 Anode electrodeposition coating process

Anodic electrophoresis process

A variant of an electrodeposited coating in which the coated components are connected as an anode and the reverse electrode is connected as a cathode

3.5 Pigment content, determined by ashing

Mass fraction of residue after ashing of the product under specified conditions

Catatan 1: It includes inorganic pigments, pengisi, and other solid components of the product that do not evaporate under test conditions, but their state may change.

3.6 Baking Process

The final drying and chemical crosslinking process of the applied paint film is initiated by heating

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

3.7 Baking loss

Volatiles released under standard baking conditions

Catatan 1: Baking loss includes reaction loss.

3.8 Entry Tags

Visible defects that occur during the immersion of the panel under voltage, usually in the form of streaks parallel to the bath surface on the object to be painted

Contoh:

Hash marks (lihat Gambar 5), pinholes (lihat Gambar 4), mappings (lihat Gambar 3).

3.9 Pelapis yang diendapkan secara elektro

Electronic coating

Waterborne coatings for electrophoretic coating

3.10 Deposition time

The time that voltage is applied between anode and cathode during the coating process

3.11 Flores

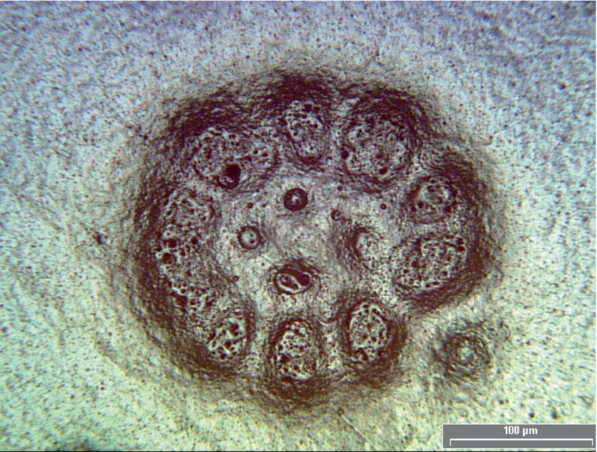

Flower-shaped craters, formed by a combination of single craters

Catatan Masuk 1: Lihat Gambar 2 for an example.

Angka 2 – Flores’ example

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

3.12 Perlindungan tepi

The ability to protect edges from corrosion

Catatan Artikel 1: Edges may be produced by drilling, meninju, and cutting.

3.13 Edge corrosion

Corrosion due to inadequate edge protection (3.12)

Catatan Artikel 1: Edges may be produced by drilling, meninju, and cutting.

3.14 Cathode electrodeposition coating process

Cathodic electrophoresis

A variant of an electrodeposited coating in which the coated parts are connected as a cathode and the reverse electrode is connected as an anode

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

3.15 Bacteria count

Colony count

The number of colony forming units (CFU) to form a macroscopically countable colony

3.16 Mapping

Local differences in film thickness in electrodeposited films

Catatan Masuk 1: Lihat Gambar 3 for an example.

Angka 3 – Mapping example

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

3.17 Pinholes

The holes in the coating extend all the way to the substrate

Catatan Artikel 1: Pinholes are often mixed with craters.

Catatan Masuk 2: Lihat Gambar 4 for an example.

Angka 4 – pinhole example

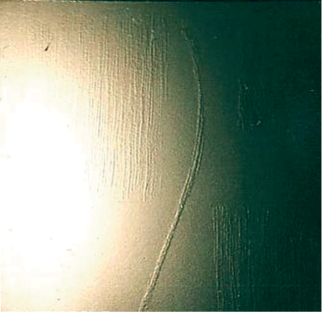

3.18 Hash tag

Hydrogen attached during the process causes characteristic depressions in the electrodeposited coating

Catatan Barang 1: One characteristic of the pound sign is the direction of the horizontal line. Secara khusus, hash marks appear when the specimen is heavily impregnated.

Catatan Masuk 2: Lihat Gambar 5 for an example. A distinct hash mark can be detected on the right side that has been moistened with softening water. On the left side of the department, there are significantly fewer hash marks.

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

3.19 Stabilitas

Electrodeposited coatings are often exposed to the aging process, especially during extended downtime (holidays, downtime, dll.), seperti:

– evaporation of water, solvents and neutralizers;

– Chemical changes in adhesives caused by air;

— bring in bacteria;

– Other reactions of the adhesive

3.20 Effort

The ability of the electrodeposited coating to penetrate the box section

3.21 Workpieces

Objects coated with material

ISO 22553-1- Cat dan pernis pelapis yang diendapkan secara elektro – Bagian 1: Kosakata

Contoh:

Pipes, radiators, vehicles, steel test plates, magnesium and aluminum alloys, pre-treated plastics.

3.22 Rupture voltage

Electrodeposition coatings deposit a potential that is no longer controllable, Misalnya, a significant change in film thickness, gas formation, or heat generation

Catatan 1: The rupture voltage can only be determined experimentally by the voltage series.

Hanya bagian informasi standar yang bersifat publik. Untuk melihat konten selengkapnya, Anda perlu membeli standar melalui saluran resmi.