- 説明

- 問い合わせ

説明

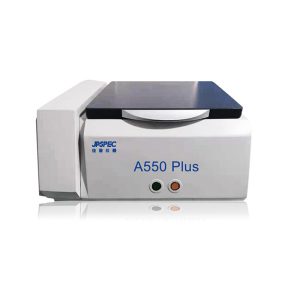

TP30PLUS RoHS phthalic tester,Pyrolytic pyrobenzene RoHS2.0 test and analysis instrument

RoHS is the Directive Restriction of Hazardous Substances (Restriction of Hazardous Substances) for the Use of Certain Hazardous Substances in Electronic and Electrical Equipment. The standard has been officially implemented in July 1, 2006, mainly used to regulate the material and process standards of electronic and electrical products; The purpose of this standard is to eliminate electric and electronic products in the lead, mercury, カドミウム, hexavalent chromium, polybrominated biphenyls (PCBS) and polybrominated diphenyl ether, a total of 6 substances, で 2019 the European Union has issued a new RoHS directive, regulations on the premise of the original six harmful substances, new phthalate n-butyl acetate (DBP), phthalic acid butyl benzyl ester (BBP), Phthalate (2-hexyl) hexyl ester (DEHP), diisobutyl phthalate (DIBP) these four kinds of toxic substances detection; 後 22 July 2019, all relevant products entering the EU must meet the criteria of RoHS2.0.

According to RoHS2.0 testing standards, production enterprises need to purchase relevant equipment for rapid screening of raw materials, material self-inspection, internal quality control, customer factory inspection, 等. (Equipment required for conventional configuration: GCMS+EDXRF spectrometer), but the purchase of these equipment at the rate of millions, many enterprises are feeling great pressure, and enterprises have to do screening of raw materials, if not screening, product production will be buried a huge hidden danger, enterprises can not control whether their products meet the standards; 例えば, the listed liquor company Drunkard was found to contain excessive phthalates (可塑剤) で 2006 due to years of neglect of internal screening and self-inspection of its products, resulting in losses of hundreds of millions of yuan and heavy losses for the company.

TP30PLUS RoHS phthalic tester,Pyrolytic pyrobenzene RoHS2.0 test and analysis instrument

TP30PLUS has the following advantages:

Advantage 1: サンプル作成時間が短い, 20 分/サンプル作成時間 * rapid screening requirements of enterprise users;

Advantage 2: 調達コストが低い, PY+GCMSの調達コストは 1.2 million, TP30PLUS procurement cost is less than 400,000;

Advantage 3: 低い使用コスト, 前処理は必要ありません, reagents and consumables, 1 年間の使用コストが以下 5000 元;

Advantage 4: 簡単な操作, direct solid or liquid injection without pre-treatment, 再現性が良い, avoid human error;

Advantage 5: 内蔵標準曲線, 材料のフタル酸が標準を超えているかどうかをより直感的に判断します;

Advantage 6: No need for professional laboratory environment, 通常の作業スペースのみを必要とし、空調電源があれば設置して使用可能.

TP30PLUS RoHS phthalic tester,Pyrolytic pyrobenzene RoHS2.0 test and analysis instrument

TP30PLUS test analyzer application case

おもちゃの中で, エレクトロニクス, 食べ物, 包装材料, 医療機器, プラスチック, ゴム, 接着剤, セルロース, 樹脂, ケーブルおよびその他の産業, 可塑剤のスクリーニング検出を行う必要がある; After years of chromatographic separation technology and basic research on plasticizer, our company has developed a plasticizer detection system that can directly inject solid and liquid samples. The system passes temperature programmed thermal analysis and high temperature cracking to allow the components in the sample to enter gas chromatograph for quantitative detection in batches according to different temperatures. The ultrafine transmission channel with specialized technology also solves the problem of overlapping analysis graphs of samples with unbalanced temperature. 同時に, 極細の伝送パイプライン自体に自動洗浄機能を搭載, それは送電パイプライン汚染の問題も解決します. このシステムは多段階の連続加熱を実現でき、サンプル終了後に手動介入なしで自動的にパイプラインを洗浄できます。, 人件費を節約するだけでなく、データの信頼性も確保します。.

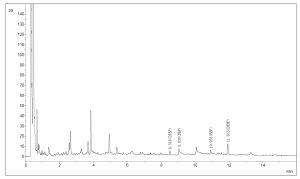

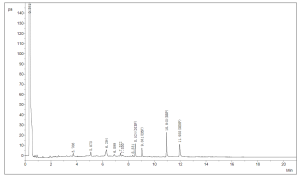

Experimental case 1, a headphone manufacturer in Shenzhen to OEM headphone plastic shell raw materials screening

1. A domestic brand gas Chromatograph (FID+SPI+ capillary column)

2, TP20 micro crack release accessory device processing equipment

3. Chromatographic column

4. A batch of other experimental equipment

注入法: direct solid injection;

Detection items: To detect whether the original PVC green particles Rohs4 phthalines exceed the standard

Detection result:

Detection result:

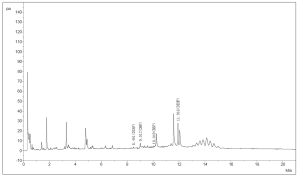

Experiment Case 2. A mobile phone charger manufacturer exported to Europe in Dongguan needs to detect and screen 4 phthalines in Rohs

1. A domestic brand gas Chromatograph (FID+SPI+ capillary column + dual-channel EPC control)

2, TP20 micro crack release accessory device processing equipment

3. Chromatographic column

4. A batch of other experimental equipment

注入法: direct solid injection;

Detection item: Detection of Ia phthalate in white PVC plastic powder

Test result of white PVC powder:

Experiment Case 2. A mobile phone manufacturer in Zhuhai needs to screen 4 phthalines in polymer material Rohs for mobile phone backplane exported to Europe

1. A domestic brand gas Chromatograph (FID+SPI+ capillary column + dual-channel EPC control)

2, TP20 micro crack release accessory device processing equipment

3. Chromatographic column

4. A batch of other experimental equipment

注入法: direct solid injection;

Detection items: Detection of 22 phthalines in polymer mobile phone back shell

Test results of mobile phone case made of polymer material::

Test case 4. Detection of phthales in cable rubber cover of a cable company in Lishui, Foshan

1. A domestic brand gas Chromatograph (FID+SPI+ capillary column + dual-channel EPC control)

2, TP20 micro crack release accessory device processing equipment

3. Chromatographic column

4. A batch of other experimental equipment

注入法: direct solid injection;

テスト項目: Phthalic acid test in cable rubber:

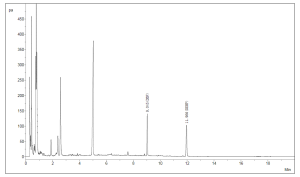

Experiment Case 4. Mixed standard products (4 kinds of phthalines, blind samples) configured by customers

1. A domestic brand gas Chromatograph (FID+SPI+ capillary column + dual-channel EPC control)

2, TP20 micro crack release accessory device processing equipment

3. Chromatographic column

4. A batch of other experimental equipment

注入法: direct liquid injection;

Detection items: Detection of 4 kinds of phthalines in blind sample (mixed label) :

TP30PLUS RoHS phthalic tester,Pyrolytic pyrobenzene RoHS2.0 test and analysis instrument

Part V: TP20-GC micro crack release attachment instrument phthalic screening instrument configuration list

TP30PLUS RoHS phthalic tester,Pyrolytic pyrobenzene RoHS2.0 test and analysis instrument

The sixth part: RoHS2.0 4 kinds of phthalic acid test application field

1. QA inspection by professional testing institutions such as customs, third-party testing institutions, 等.

2, computer, 電話, カメラ, mobile phone and other electronic manufacturing QC, IQC, IPQC, QA inspection.

3. QC, IQC, IPQC, QA inspection of toys, game consoles, sports equipment and other manufacturing industries.

4, gifts, ornaments, hardware and other manufacturing QC, IQC, IPQC, QA inspection.

5, 家具, ペイント, painting and other manufacturing QC, IQC, IPQC, QA inspection.

6, 織物, レザー, food and other manufacturing QC, IQC, IPQC, QA inspection

7, refrigerator, washing machine, microwave oven, air conditioning and other large household appliances manufacturing QC, IQC, IPQC, QA inspection.

8, vacuum cleaner, 鉄, dryer, clocks and other small household appliances manufacturing QC, IQC, IPQC, QA inspection.

9, radio, TV, Musical Instruments and other audiovisual manufacturing QC, IQC, IPQC, QA inspection.

10, 工作機械, processing equipment, power tools and other manufacturing QC, IQC, IPQC, QA inspection.

11, 業界: 繊維, 電子機器, プラスチック, 化粧品

12, food safety: 残留農薬, flavors, additives, 包装材料

13, 環境を守ること: 空気, water quality, 土壌, solid waste

14, biomedicine: pharmaceutical factory, drug testing

15. Petrochemical Industry: Oil refinery, chemical plant

16, criminal investigation, identification of material evidence.