- 설명

- 문의

설명

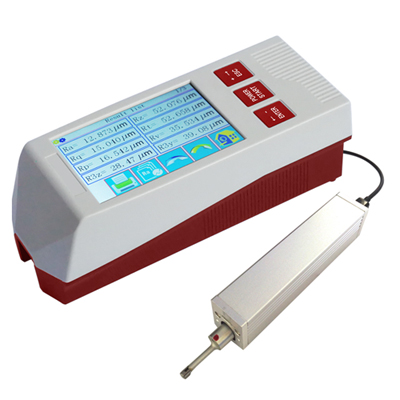

LR310 표면 거칠기 측정기

APPLICATION

표면 거칠기 시험기 엘R310 is a high accuracy instrument for measuring surface roughness. It can be used on variety of machining parts and operates on various surfaces, not only flat but also outer cone, outer cylinder, curved, pinholes, grooves, recesses grooves and axle etc.

그만큼 엘R310 allows surface roughness measurement both on metal and non-metal workpieces. especially for measurement on large and heavy workpiece, assembly line, 현장에서. It is suitable for machining and manufacturing, 품질 관리, inspection departments.

The LR310 is a Non Destructive Testing instrument, damage won’t caused to testing piece.

LR310 표면 거칠기 측정기

주요 특징

- Mechatronics and ergonomics design, small size, 가벼운 무게, easy to operation

- The stylus drive unit can be stored within the main unit for standard measurement, or separated from the display unit by using the supplied cable which allows more flexible measurement in any orientation. The driver can be separated and reattached in one simple step

- 5 inches color graphic LCDtouch screen, WYSIWYG, it includes a backlight for visibility in dark environments

- It displays all parameterand graphic

- 그만큼 엘R310 can be operated usingthe buttons or the touch screen

- Measurement range up to 320μm

- Large internal memory: 100 item of raw data and curves can be stored

- 그만큼 엘R310provides Bluetooth Capability , support wireless connection with printer

- Built-in lithium-ion rechargeable battery and controlling circuit, high capacity, 메모리 효과 없음

- There is remaining charge indicator, charging hint

- It works over 50 hours while fully charged.

- 언어: 중국어와 영어

- DSP chip control and data processing, 고속, 저전력 소비

- Real-time clock setting and display for easy data recording and storage

- With auto sleep, auto power off, power-saving features

- Reliable circuit and software design to preventing the motor stuck

- All parameters or any of the parameters which set by users can be printedLR310 표면 거칠기 측정기

기술 데이터

Measuring rang The Z axis (수직의) 320μm (-160µm~160µm) , 12600μin (-6300μin~+6300μin) The X axis (Transverse) 17.5mm(0.69 inch) 해결 the Z axis (수직의) 0.002μm/±20μm, 0.004μm/±40μm 0.008μm/±80μm, 0.02μm/±160μm

매개변수 Ra Rz Rq Rt Rc Rp Rv R3z R3y Rz(그) Ry Rs Rsk Rku Rmax Rsm Rmr RPc Rk Rpk Rvk Mr1 Mr2

Graphic Rmr curve, Roughness curve, Primary Profile 필터 RC,PC-RC,Gauss,DP The sampling length(엘아르 자형) 0.25, 0.8, 2.5mm Assessment length(엘n) 엘n= 엘r×n n=1~5 감지기 Measuring principle Inductance Stylus tip 다이아몬드, 90 cone angle, 5μmR 힘 Measuring force<4백만, Skid force<400백만 Probe head 단단한 합금, skid radius of curvature: 40mm Traversing speed 엘r=0.25, Vt=0.135mm/s lr=0.8, Vt=0. 5밀리미터/초 lr=2. 5, Vt=1mm/s Return Vt=1mm/s 정도 0.001μm 용인 Not more than ±(5nm+10%A) A stands for the standard specimen RA value( tolerance not more±10% ) Residual Profile Not more than 0.010μm 반복성 not more than 3% 전원 공급 장치 Built-in Lithium ion battery 3200mAh, Charger :DC5V Outline dimension Main unit: 158×55×52mm drive unit: 23×27×115mm Weight(main unit) Around 380g Zoom of height adapter 40mm working Environment 온도: – 20℃ ~ 40℃ 습기: < 90% RH

Store and Transportation 온도: – 40℃ ~ 60℃ 습기: < 90% RH

표준 ISO4287, ANSI B46.1, DIN4768, JIS B601 Optional accessory Magnetic Base, height gauge adapter, curved sensor, small hole sensor, deep groove sensor, pinhole sensor, Extending Rod, Right Angle Rod, mini printer, 200mm platform, 300mm marble platform, 소프트웨어, mobile APP