Het kleurbehoud van de film werd gemeten met een kleurverschilmeter

Als sleutelelement voor oppervlaktebescherming en verfraaiing, de coatingfilm moet niet alleen goede mechanische eigenschappen hebben, maar moet ook weerstand bieden aan de inbreuk op externe factoren zoals licht, warmte en elektriciteit tijdens gebruik. Onder hen, kleurbehoud verwijst naar het vermogen van de coating om zijn oorspronkelijke kleur te behouden onder blootstelling aan licht. Het detecteren van kleurbehoud is voor diverse toepassingen van belang, van autolakken tot architecturale decoratie, to ensure that the film does not fade or change color under light conditions. This paper will introduce the importance of color retention and detection methods, especially the instrument determination method using GB/T 9761 methode.

In many application scenarios, the color of the film is often an important part of the appearance of the product, and it is also closely related to the brand identity and design concept. Whether it is cars, home furniture or buildings, consumers usually expect the color of the film to be durable and bright, and will not change due to long-term light. In aanvulling, color consistency is also crucial for quality control in production, especially when mass production is required to ensure that the color of each product remains consistent.

Het kleurbehoud van de film werd gemeten met een kleurverschilmeter

Detectiemethode

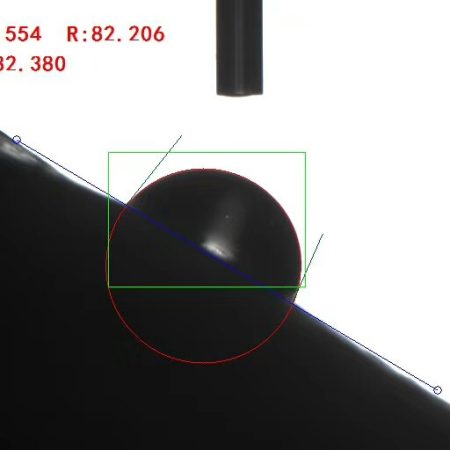

In order to evaluate the color retention of the film, the visual method and the instrument method are usually used. Onder hen, the instrument method, in accordance with the provisions of GB/T 9761, is a more accurate and reproducible method, especially for applications requiring quantified data.

The specific detection steps are as follows:

Prepare the test film template to ensure that the color meets the product requirements.

Place the color difference meter on the template to ensure that the light source is stable.

Use a color difference meter to select the appropriate measurement mode and record the color value before irradiation.

The coating template is exposed to light for a certain time to simulate actual use.

The color value after irradiation was measured again with a color difference meter.

Calculate the color retention, dat is, the color value after irradiation divided by the color value before irradiation.

Based on the results of the calculation, the color retention of the coating can be assessed, usually using the following criteria to classify:

Color retention =1, indicating that the film completely maintains the primary color without color change.

Color retention 1, indicates that the color of the film has changed, and the smaller the value, the more serious the change.

Het kleurbehoud van de film werd gemeten met een kleurverschilmeter

Toepassingsveld

The test of color retention has been widely used in various fields. Bijvoorbeeld, in the automotive industry, the color consistency of the coating film is crucial for quality control on the production line. In architectural decoration, it is necessary to ensure that the color of the wall coating remains bright for a long time to maintain the decorative effect. In aanvulling, in the furniture manufacturing and electronic product manufacturing, color retention testing is also indispensable to ensure the stability and quality of the appearance of the product.

The color retention of the film is one of the key properties to ensure that the product retains its primary color under light exposure. In order to evaluate and ensure the color retention of the coating, de instrumentele methode van GB/T 9761 provides highly repeatable and accurate results. Deze detectiemethode heeft een breed scala aan toepassingen, helping manufacturers to provide high-quality products to meet consumer needs for color stability, while maintaining brand reputation and market competitiveness. Daarom, the research and detection of color retention is of great significance in the field of coating inspection