Asphalt Needle Penetration Meter Tester Machine

- Description

- Inquiry

Description

Asphalt Needle Penetration Meter Tester Machine

I. Overview

Asphalt penetration meter is an instrument for measuring asphalt penetration, which is developed by using advanced capacitance digital dial indicator and numerical control circuit. The instrument meets the requirements of GB4509-84 “petroleum asphalt penetration measurement method” and T0604-2000 “asphalt penetration test”. It is easy to use, convenient and does not need preheating. It is suitable for highway, Municipal Administration, construction, transportation and transportation in China Petroleum and other fields provide a high-precision advanced instrument.

II. Purpose

The instrument is mainly used for penetration of viscous road asphalt, liquid oil, asphalt and residue of asphalt material after distillation or emulsification test.

Asphalt Needle Penetration Meter Tester Machine

III. Technical index

1. Minimum Division: 0.01mm

2. Measurement range: 0-50mm

3. Weight of standard needle and needle: 100 ± 0.05g

5. Power supply: 230 V

6. Sample dish: flat bottomed cylinder, made of metal, the size is 55 × 35mm

7. Flat bottom heat preservation dish: glass product, with a capacity of more than 15L and a depth of more than 60mm. A quadrangle grid frame is used to attach the sample dish.

8. The working platform of the instrument is equipped with a level adjusting mechanism.

IV. Use of instruments

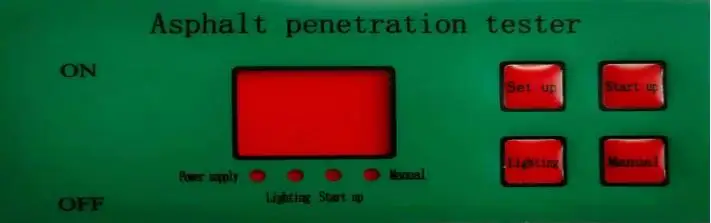

1. Introduction to instrument operation panel

“Set” key: set the descending time. Press the “set” key, and the screen will display the descent time. At this time, press the “start” key, and the descent time will increase by 1s. Press the “manual” key, and the descent time will decrease by 1s.

Start key: used to start the test. When the needle in time is set, press the key to start the test. Under other pages, the function of the key is redefined.

“Manual” key: under the test interface, press the key to lock the electromagnet of the needle rod to close, and the needle rod loses the lock. Release the key, and the needle rod is locked. Under other pages, the function of the key is redefined.

“Lighting” key: press the lighting to start, and then press the lighting to turn off.

V. Operating procedures

1. Adjust the penetrometer to make it level.

2. Fill the glass constant temperature water bath with water, the water level is about to the glass bath mouth, and put the water bath on the chassis platform.

3. Move the sample meeting the constant temperature requirement into the triangle bracket in the glass bath, slowly adjust the height of the displacement sensor bracket, install the standard needle of the penetration meter, make the needle tip just contact with the surface of the test piece, press the start button to start the test, and the instrument will automatically complete the one-time penetration process.

4. After the three tests, the average value of the three test data is taken as the test result.

5. The instrument has set the curing temperature at 25 ℃ and the injection time at 5 seconds.

6. After each test, the instrument must be cleaned and dried in time.

VI. Precautions

1. Before each test, the water temperature in the incubator should be checked and adjusted. After the test, the installed standard needle should be removed and cleaned with cotton or cloth soaked with solvent (benzene or gasoline); Dry with cotton or cloth and store in a dry place.

2. If the parts of the instrument are damaged or lost, please contact the seller of our company. Do not disassemble them by yourself.

3. To ensure safety, please use a power supply with ground wire.