Viscosity cup introduction and selection guide

Viscosity cups are an important laboratory and production site tool for measuring the viscosity of liquids such as coatings, paints and inks. They are divided into various types according to the design and use occasion, including Tu-4 cup, ISO outflow cup, JIS Iwata cup, ZAHN Zeon Cup, Ford Ford Cup, etc. This article will give a detailed introduction to these viscosity cups and provide selection guidelines.

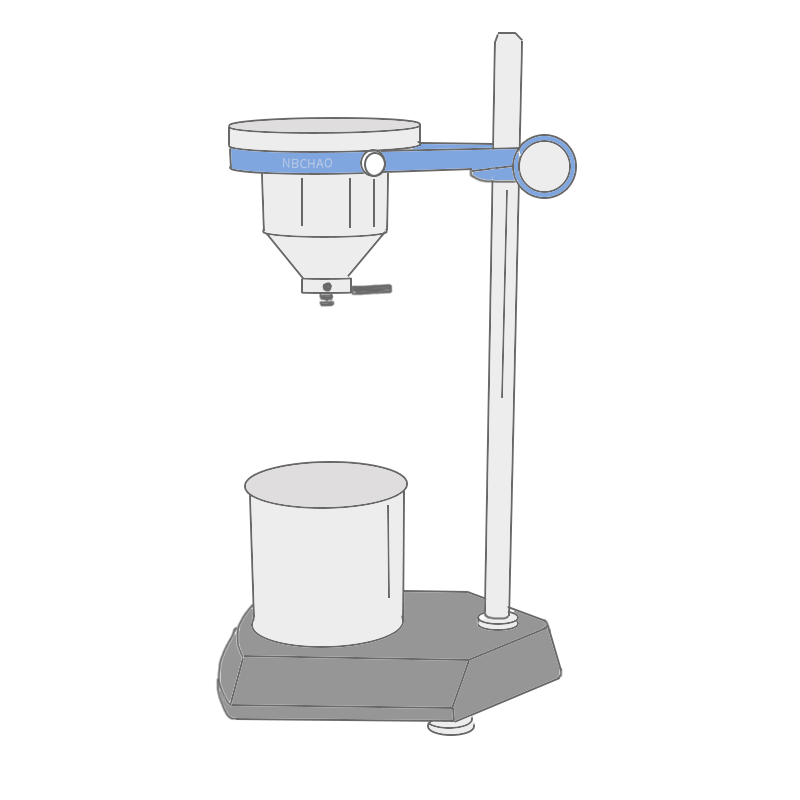

How the viscosity cup works

The viscosity cup uses the principle of gravity to calculate the time for fluid to flow out of a specified aperture size to measure viscosity. Viscosity indicates the internal resistance of the liquid to flow, reflecting the degree of viscosity and thinness of the paint. Accurate measurement of viscosity is essential to ensure the quality and performance of materials such as coatings and paints.

Viscosity cup introduction and selection guide

Various viscosity cups are introduced

Coating -4 cups: according to the national standard GB/T1723 design, widely used in the paint, paint, ink industry laboratory or production site. It is characterized by a cylindrical upper and conical lower container with a capacity of 100mL and a standard 4mm stainless steel leaky nozzle at the bottom.

ISO Discharge cup: Designed according to ISO 2431-1993 and GB/T 6753.4-98, applicable to international standards, for measuring the discharge time of Newtonian or near-Newtonian liquids.

JIS Iwata cup: Designed according to Japanese JIS standard, it is mainly used for on-site rapid measurement of electronic products and plastic coatings industry.

ZAHN Cup: Designed according to ASTM D4212-93 for viscosity measurement of Newtonian or near-Newtonian liquids, commonly used in workshops, factories and laboratories.

Ford Cup: Designed according to ASTM D1200 standard, the function and use method are the same as other viscosity cups, commonly used in the coatings and paints industry.

Selection guide

When choosing a viscosity cup, the following factors should be considered:

Viscosity cup type

Determine if you need to coat -4 cups, ISO drain cups, JIS Iwata cups, etc., based on the application scenario and desired accuracy.

Shape and material

Depending on the application environment (laboratory or production site), choose a handheld or benchtop viscosity cup and consider the body material (e.g., stainless steel, aluminum).

Maximum viscosity value

Choose a cup that meets the viscosity range of the test liquid.

Orifice diameter

Select the appropriate outflow aperture according to the viscosity of the liquid.

Applicable standard

Ensure viscosity cups comply with required industry standards such as ISO, ASTM, etc.

Error range

Select an error range based on accuracy requirements and consider whether a calibration certificate is required.

Viscosity cup introduction and selection guide

conclusion

Viscosity cups are indispensable tools for coatings, paints, inks and other industries. Choosing the right viscosity cup can not only ensure product quality, but also improve work efficiency. With the above guide, you can better understand and choose the right viscosity cup for your needs.