Application of scraper coating machine in preparation of foam coating

The coating machine plays a crucial role in the coating preparation. In the foam coating finishing process, the foam coating finishing aims to evenly and completely coat the prepared foam on the surface of the fabric, and adhere to the surface of the substrate after heat treatment and drying, so as to improve the performance of the substrate and obtain a material with excellent performance. Its main function is to evenly coat the coating, solution or other materials on the surface of the substrate to ensure the uniformity and quality of the coating. After the coating is complete, the coating machine can also assist with subsequent treatments, such as heat treatment or curing, to ensure that the resulting coating has the desired properties and characteristics.

Application of scraper coating machine in preparation of foam coating

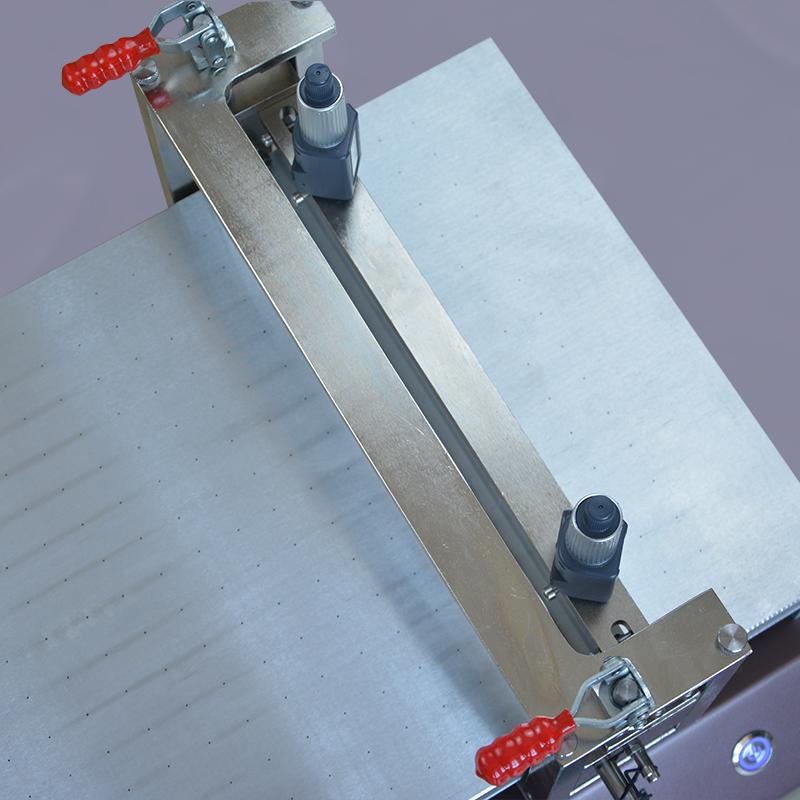

In the scraper coating method, the coating machine plays a key role. It uses a scraper to apply foaming solution to the surface of the base cloth, and the foam is applied to the surface of the base cloth through the downward pressure of the scraper. After the coating is completed, the coated glass fiber cloth must be heat treated immediately to avoid excessive foam penetration and rupture, and to ensure that the intact foam structure is preserved. This heat treatment process is usually divided into three stages.

The first stage is low temperature drying, the drying temperature range is between 120-180℃, the main purpose is to evaporate the water in the foam coating, so as to obtain a dry coating structure, retain the bubble structure, and lay the foundation for the subsequent formation of microporous coating structure.

The second stage is high temperature sintering, the sintering range is usually between 330-380℃. The coated glass fiber cloth is sintered near the melting point of PTFE to remove all impurities in the foam coating, and PTFE can remain stable at this temperature and will not decompose, thus forming a PTFE microporous structure with certain mechanical properties and dimensional stability.

The third stage is a slow cooling treatment, with a temperature range between 360 ° C and 100 ° C. At this stage, the structure of the coating is further optimized. According to the previous experimental results, after heat treatment of the PTFE hollow fiber film, it is placed in a cooling oven and continued heat treatment for a period of time, and the hollow fiber film with more pores and better performance can be obtained. This indicates that heat preservation has a positive effect on the improvement of pore structure.

Application of scraper coating machine in preparation of foam coating

In the process of preparing PTFE foam-coated glass fiber composite filter materials, the coating machine also plays an indispensable role. This complex material preparation process requires precise steps and efficient equipment, and the coating machine is one of them, which is related to the uniform coverage of the coating on the glass fiber substrate and the excellent coating quality.

First, the raw materials such as PTFE emulsion, betaine, Tine, acrylic resin and methyl cellulose are precisely distributed through the pipette, and mixed together according to a certain formula ratio to form the prepared PTFE foam solution. The accuracy of this step is crucial to the subsequent coating process, on which the coating machine needs to accurately apply this complex coating. Then the coating machine comes into play. The solution is stirred with a high speed stirring rod to quickly produce and obtain foaming solution. In the case of the operation of the coating machine, by the uniform speed of the scraper, the foam is coated on the substrate to ensure that the foam is evenly coated and does not destroy its structure. After the coating is completed, the coated glass fiber substrate is immediately sent to the hot air dryer for a short drying treatment, and it is sent to the preset temperature for rapid drying. At this time, the coating effect of the coating machine is crucial to the quality of the subsequent steps. Next comes the sintering process, where the coating prepared by the coating mechanism needs to be briefly sintered at high temperatures. After the completion of sintering, the coated glass fiber substrate needs to continue to undergo slow cooling treatment, which is a key step to ensure the structural stability and performance consistency of the coating.

After this series of precise and complex steps, the coating machine successfully achieved the preparation of PTFE foam coated glass fiber composite filter material. This film coating machine plays a key role in this process, ensuring the uniformity and quality of the coating and giving the final product the desired filtration performance and stability.