Ceramic coatings and coating properties test

Measuring ceramic coatings and their coating properties is a key step to ensure product quality and performance stability. These tests not only verify the effectiveness of the coating formulation and preparation process, but also assess the stability and durability of the coating under different conditions. Understanding the performance parameters of ceramic coatings, such as pH, gel time, hardness and adhesion, helps manufacturers optimize product design, improve production processes, and ensure that the final product meets the expected standards and usage requirements, thus meeting customer needs and ensuring product performance stability and reliability in practical applications.

pH test

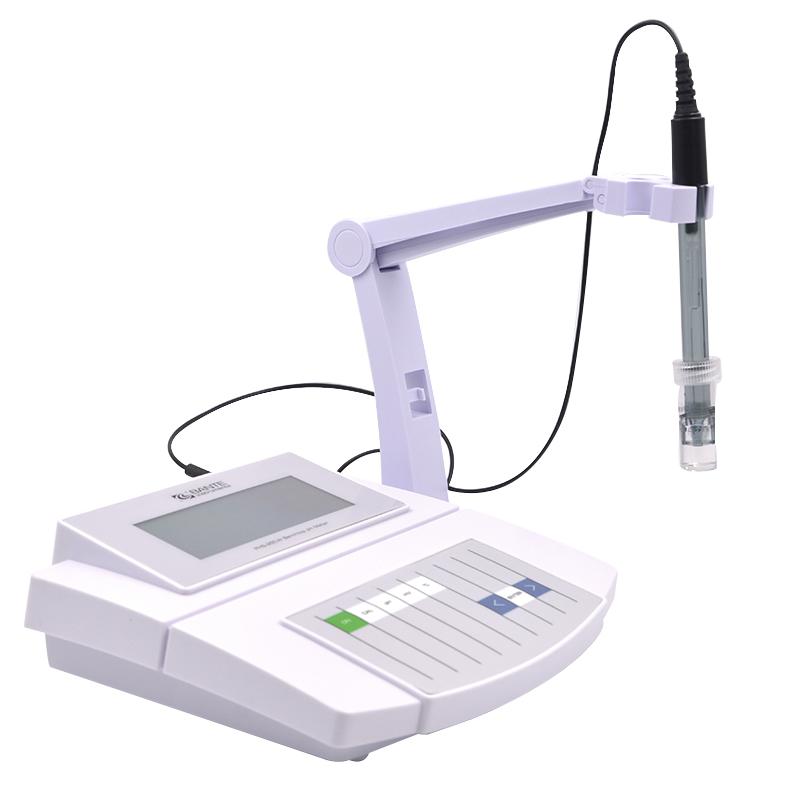

pH value is an important parameter in the preparation of ceramic coatings. Through the pH test, it is possible to determine the content of acidic or alkaline components in the paint, which is crucial for the quality and stability of the paint. The pH test strip is a simple preliminary measurement tool that provides a rough pH range at room temperature. The portable pH meter (PHS-25) provides more accurate results and is a reliable tool for accurate pH measurement of reaction systems.

Ceramic coatings and coating properties test

Gel time test

Gel time refers to the time when the paint begins to gel or cure under certain conditions. This test is to evaluate specific properties of the paint, such as stability at different temperatures or humidity. By placing the ceramic coatings prepared in the experiment at room temperature and recording the time, the information of gel time can be obtained.

Pencil hardness test

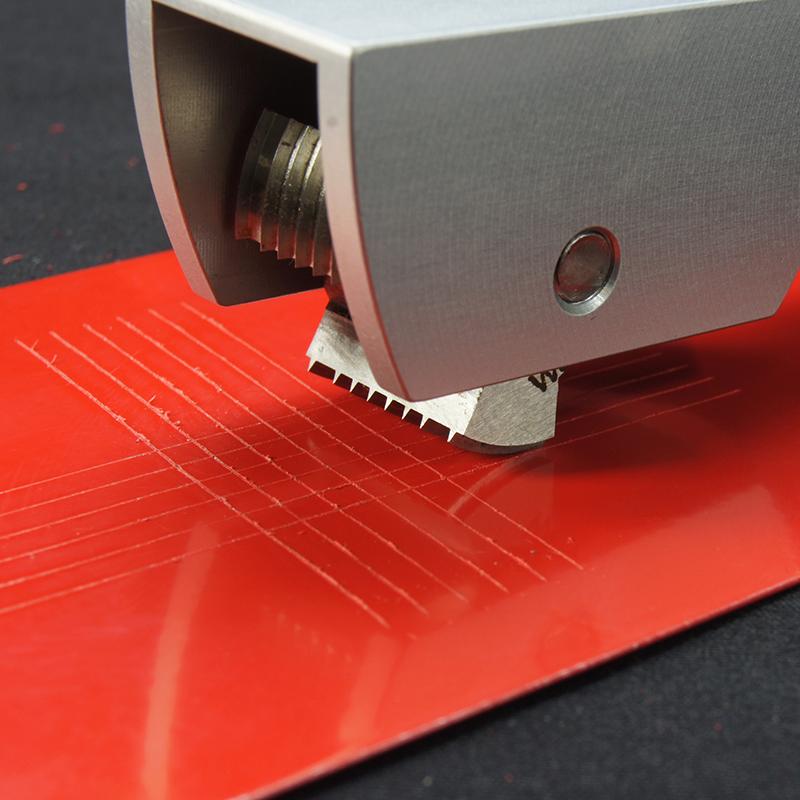

The pencil hardness test is one of the ways to evaluate the hardness of the coating. According to the national standard GB/T 6739, the pencil hardness of the coating was determined by the trolley method. Specifically, by using pencils with different hardness (such as 6H, 5H, etc.) to scratch the surface of the coating, observe and compare the depth of the scratch to determine the hardness level of the coating.

Adhesion test

The purpose of the adhesion test is to evaluate the strength of adhesion between the paint and the substrate. According to the provisions of national standard GB/T 9286, the adhesion of ceramic coatings is tested by using the hundred-grid method. This test method involves cutting out a cross-shaped lattice pattern, and then observing the degree of adhesion and damage between the coating and the substrate to determine the adhesion level of the coating.

Ceramic coatings and coating properties test

Through these detailed test methods and standards, the performance of ceramic coatings and coatings can be evaluated more comprehensively. These tests not only help manufacturers ensure that products meet quality requirements, but also help improve coating preparation processes and product performance.