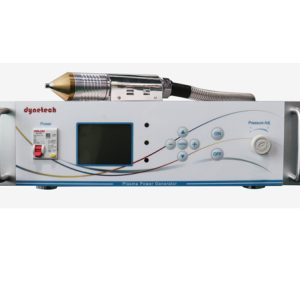

Processeur de pré-impression de codage UV LRGM-2000

- Description

- Enquête

Description

UV coding pre-print processor,Nettoyant plasma,plasma surface cleaning machine

Direct injection plasma surface processor

A variety of sprinkler heads can be selected to meet the needs of different products

Speed adjustable Power adjustable

UV coding pre-print processor,Nettoyant plasma,plasma surface cleaning machine

UV coding pre-print processor,Nettoyant plasma,plasma surface cleaning machine

Caractéristiques du produit

Modification de la surface du produit

La modification de l'équipement plasma Fangrui peut réduire efficacement les facteurs d'influence du prétraitement des matériaux en 95%

Activation de la surface du produit

Le taux d'activation de surface des matériaux prétraités avec l'équipement plasma Fangrui est 98%

Nettoyage de la surface du produit

La modification de l'équipement plasma Fangrui peut réduire efficacement les facteurs d'influence du prétraitement des matériaux en 95%

Collage de la surface du produit

L'adhérence de la surface du matériau a été améliorée par 92% en utilisant l'équipement plasma Fangrui

1. What does plasma surface processor (cleaning machine) do?

Plasma surface processor uses current to generate normal temperature plasma to act on the tongue surface of various packaging such as toothpaste box, boîte à cigarettes, wine box and gift box. After processing and gluing, there will be no ungluing problem, and you can paste the box with ordinary glue, greatly reducing the cost of glue.

Is your company using a fully automatic box paste machine? The plasma surface processor can be used together with the box paste machine.

2.What are the products of plasma surface processor?

UN: Currently on the market is the common single nozzle plasma surface processor. And our company has developed a number of products such as double nozzle, three nozzle, rotating nozzle, etc.. Our professional R & D team can also specialize in R & D and production according to customers’ needs.

3.Main functions and advantages of plasma surface processor?

UN: 1. Spray plasma flow is neutral, can be a variety of polymer, verre, métal, semi-conducteur, caoutchouc, PCB circuit board and other materials for surface treatment.

2. Plasma surface processor after treatment to remove hydrogen carbide dirt, such as grease, auxiliary additives, is conducive to bonding, durable and stable performance, long retention time.

3 plasma temperature is high and low, for different materials to choose different temperature plasma, (power size can be adjusted) suitable for those surface materials sensitive to temperature products.

4. Every type of atmospheric pressure equipment has on-line function! Can be directly installed on the production line, with field equipment online operation processing! Relative to the reverse operation of edging machine, greatly improve the work efficiency.

5. Only air and electricity are consumed, so the operation cost is low and the operation is safer.

6. Dry method treatment without pollution, no waste water, meet the requirements of environmental protection; And replace the traditional edging machine, put an end to the impact of paper powder paper wool on the environment and equipment.

7. After plasma surface processor treatment, ordinary glue can be used to stick the box, reducing the production cost. Plasma processor introduction: plasma technology is a good solution to the coated paper, glazing paper, papier d'emballage, papier plaqué aluminium, UV coating, PP, PET and other materials bonding is not strong, or unable to bond the problem. To solve the problem that many enterprises used to use the traditional local coating, local glazing, surface grinding or cutting paste line, the use of special glue to improve the bonding method.

Plasma technology after the use of ordinary water-based glue can be very good bonding, no longer because of different cardboard and replace different glue. Not only effectively solve the paste box, paste box production process problems, but also have a good guarantee for the enterprise’s process, efficacité, qualité.

4.Selective surface modification can be achieved by plasma processing:

1. Activation: greatly improve the wettability of the surface, forming an active surface

2. Cleaning: Remove dust and oil, fine cleaning and electrostatic removal

3. enrobage: A functional surface is provided by a surface coating treatment

4. Improve the adhesion ability of the surface

5. Improve the reliability and durability of surface bonding

UV coding pre-print processor,Nettoyant plasma,plasma surface cleaning machine

Champ d'application:

Tous types de nettoyage de surfaces vitrées, améliorer l'hydrophilie de la surface du verre, optimize the glass coating, impression, technologie de collage et de pulvérisation;

Flexible and non-flexible printed circuit board contact cleaning, Lampe fluorescente LED “contact” nettoyer et améliorer la fermeté de l'adhésif de la surface;

Electronic components, Nettoyage des PCB, Nettoyage des surfaces IC, liaison d'amélioration d'activation, etc.;

Plasma cleaning before LCD terminal lamination;

Automotive industry application

Automotive EPDM seal strip, flocking and pre-coating pretreatment instead of using base coating;

Car lamp base, groove, plaquette de frein, bumper bonding, plasma pretreatment before spraying;

Pre-treatment of automobile anti-puncture tire before gluing;

New energy vehicle lithium battery electrode plate welding, coating surface activation, cleaning, etc.;

Plastics industry application

PP, PVC, ANIMAL DE COMPAGNIE, PC, PE, PTFE and other types of plastic materials spraying, impression, galvanoplastie, bonding and flocking before treatment.

All kinds of plastic, silicone, caoutchouc, metal and other materials spraying, impression, galvanoplastie, bonding before surface modification, removal of surface pollutants;

Mobile phones, des ordinateurs, toys and other plastic shell printing, spray pretreatment, improve surface adhesion;

Plastic cosmetic bottle preprocessing before printing, improve the surface adhesion can prevent word falling off and improve product quality;

Packaging industry application

Papier couché amélioré professionnel, glazing paper, polishing, carte d'or et d'argent, papier plaqué aluminium, UV, PPO, PP, PET et autres boîtes de couleurs, Surface de la boîte de couleur, solidité de la boîte à pâte;

Plasma pretreatment of milk powder cans and beverage cans before welding;

Printing and coding industry applications

Prétraitement plasma avant tampographie, sérigraphie et jet coding sur la surface du plastique, métal, verre et autres matériaux composites pour améliorer l'adhérence de la surface du matériau à l'encre;

PE, PTFE, silicone rubber wire and cable coding before processing;

PVC, ANIMAL DE COMPAGNIE, ABS smart card pre-processing;

Appliance industry application

Plasma activation before coating, spraying and bonding of daily necessities and household appliances can improve the surface adhesion and bonding force of products.

Health pot heating plate plasma cleaning enhanced glue adhesion, firmness, etc.;