Machine de traitement de surface au plasma LRPM-V84 FPC

- Description

- Enquête

Description

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

Caractéristiques du produit

1. Change the surface properties of materials to improve adhesion

2. It can be connected with the production line to realize automatic production

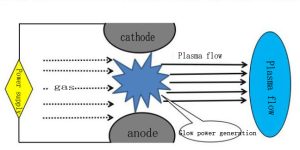

3 Low temperature plasma cold arc discharge technology

4. Optional multiple types of nozzles, wide range of use

5. Improve production quality, environmental protection and energy saving

6. Good security, multifunctional safety protection

Plasma cleaning principle: plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching.

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

Industrie des applications

Photoelectric and electronic industry applications

1. Tous types de nettoyage de surfaces vitrées, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. Flexible and non-flexible printed circuit board contact cleaning, Lampe fluorescente LED “contact cleaning and improve the surface glue fastness;

3 Electronic components PCB cleaning, Nettoyage des surfaces IC, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

Automotive industry application

1. Automotive EPDM seal strip, flocking and pre-coating pretreatment instead of using base coating;

2. Car lamp base, groove, plaquette de frein, bumper bonding, plasma pretreatment before spraying;

3 Pre-treatment of automobile anti-puncture tire before gluing:

4. New energy automobile battery electrode welding, coating surface activation, cleaning, etc.

Plastics industry application

1.PP, PVC, ANIMAL DE COMPAGNIE, PC, PE, PTFE and other plastic materials spraying, impression, galvanoplastie, bonding and flocking pre-treatment;

2. All kinds of plastic, silicone, caoutchouc, metal and other materials spraying, impression, plating bonding before surface modification, removal of surface pollutants;

3. Pretreatment before printing and painting of mobile phones, des ordinateurs, toys and other plastic shells to improve surface adhesion;

4. Plastic cosmetic bottle preprocessing before printing, improve surface adhesion can prevent word falling off and improve product quality;

Packaging industry application

1. Professional improvement of coated paper, glazing paper, polishing, carte d'or et d'argent, papier plaqué aluminium, UV, PPO, PP, PET et autres boîtes de couleurs, Surface de la boîte de couleur, solidité de la boîte à pâte;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

Printing and coding industry applications

1. Prétraitement plasma avant tampographie, sérigraphie et jet coding sur la surface du plastique, métal, glass and other composite materials to

improve the adhesion of material surface to ink;

2.PE, PTFE, silicone rubber wire and cable coding before processing 3.PVC, ANIMAL DE COMPAGNIE, ABS smart card coding before pretreatment

Appliance industry application

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

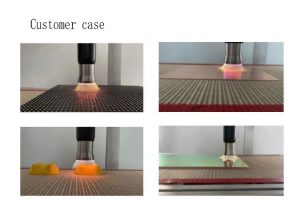

Customer case