- 説明

- 問い合わせ

説明

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

製品の特徴

1. Change the surface properties of materials to improve adhesion

2. It can be connected with the production line to realize automatic production

3 Low temperature plasma cold arc discharge technology

4. Optional multiple types of nozzles, wide range of use

5. Improve production quality, environmental protection and energy saving

6. Good security, multifunctional safety protection

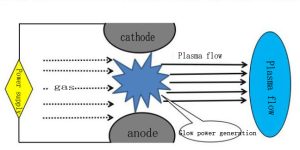

Plasma cleaning principle: plasma cleaning technology uses the characteristics of low temperature plasma to contact and react with the surface of the material, so that the surface of the material being treated can be cleaned chemically and physically, improve the surface moistness, implant new chemical functional groups and surface etching.

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

FPC plasma surface treatment machine clean activated surface modification,Four nozzle corona processor

アプリケーション産業

Photoelectric and electronic industry applications

1. 各種ガラス表面の洗浄, improve the hydrophilicity of glass surface, optimize the process of glass coating printing, bonding and spraying;

2. フレキシブルおよび非フレキシブルプリント基板の接点のクリーニング, LED蛍光灯 “contact cleaning and improve the surface glue fastness;

3 電子部品基板洗浄, IC表面の洗浄, activation enhancement binding and other

4.LCD terminals before bonding plasma cleaning;

自動車産業への応用

1. 自動車用EPDMシールストリップ, ベースコートを使用せずに植毛とプレコートの前処理を行う;

2. 車のランプベース, 溝, ブレーキパッド, バンパー接着, スプレー前のプラズマ前処理;

3 自動車用耐パンクタイヤの接着前前処理:

4. New energy automobile battery electrode welding, コーティング表面の活性化, クリーニング, 等

プラスチック産業への応用

1.PP, PVC, ペット, パソコン, PE, PTFE and other plastic materials spraying, 印刷, 電気めっき, bonding and flocking pre-treatment;

2. あらゆる種類のプラスチック, シリコーン, ゴム, 金属およびその他の材料の溶射, 印刷, plating bonding before surface modification, 表面汚染物質の除去;

3. Pretreatment before printing and painting of mobile phones, コンピュータ, toys and other plastic shells to improve surface adhesion;

4. ペット化粧品ボトルの印刷前前処理, improve surface adhesion can prevent word falling off and improve product quality;

包装業界への応用

1. Professional improvement of coated paper, 光沢紙, 研磨, ゴールドとシルバーのカード, アルミメッキ紙, 紫外線, OPP, PP, PET等のカラーボックス, カラーボックス表面ペーストボックス堅牢度;

2. Plasma pretreatment before welding of milk powder cans and beverage cans;

印刷およびコーディング業界のアプリケーション

1. パッド印刷前のプラズマ前処理, プラスチック表面へのスクリーン印刷とジェットコーディング, 金属, glass and other composite materials to

improve the adhesion of material surface to ink;

2.PE, PTFE, silicone rubber wire and cable coding before processing 3.PVC, ペット, ABS smart card coding before pretreatment

家電業界への応用

1. Plasma activation before surface coating, spraying and bonding of daily necessities and household appliances can improve surface adhesion and bonding force.

2. Printing before processing, can make the printing more firm not to fall off

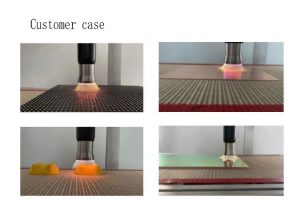

Customer case