LR-58 Pipe drop weight impact test equipment

- Description

- Inquiry

Description

Pipe drop weight impact test equipment

In line with GB/T 14152-2001 “Thermoplastic pipe resistance to external impact performance test method, clockwise rotation method”, GB/T 14153-2001 “hard plastics drop hammer test method General rules”, while meeting the requirements of ISO 3127 test equipment, suitable for all kinds of plates, pipes drop hammer impact test.

Working environment and conditions of pipe drop hammer impact testing machine

Ambient temperature: 10℃ ~ 40℃ range;

The relative humidity of the environment is within 30% ~ 80%;

In an environment without vibration or corrosive media;

Properly installed on a solid foundation and adjusted to level.

When working, there is no strong magnetic field interference and no strong convection in the surrounding air.

Pipe drop weight impact test equipment

Usage method

(1) Power on the machine in the control cabinet;

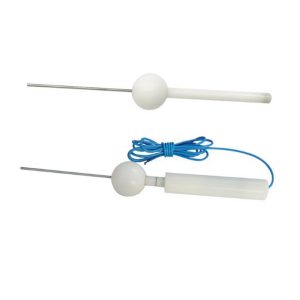

(2) Select V-shaped platform according to the diameter of the pipe to be measured, small diameter pipe small V-shaped platform, large diameter pipe with large V-shaped platform. The hammer weight and impact height are selected according to the standard of the part under test.

| Use temperature | 10℃~35℃ |

| there is no large vibration source nearby, no strong electromagnetic field; | |

| there is no corrosive medium in the environment, and pay attention to good ventilation of the electric control box; | |

| power supply | AC 220V±10% 5A 50Hz |

| table stroke | 0~400mm |

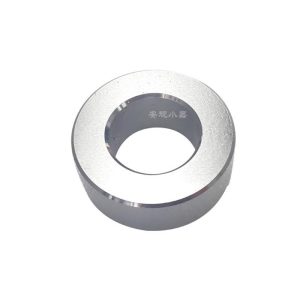

| Hammer head | SR5, SR 10, SR 30, d25, d907, d90 |

| Impact height | 0~2000mm |

| height positioning error | ±5mm |

| overall size | host (length × width × height) 730mm×600mm× 3700mm |

| the whole weight | about 500kg |

Pipe drop weight impact test equipment