ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

Bir Önsöz

ISO (Uluslararası Standardizasyon Örgütü) ulusal standart kuruluşlarından oluşan küresel bir federasyondur (ISO üyesi kuruluşlar). Uluslararası standartların geliştirilmesi genellikle ISO teknik komiteleri aracılığıyla yürütülür.. Teknik komitenin kurulduğu konuyla ilgilenen her üye grubu komitede temsil edilme hakkına sahiptir.. Uluslararası organizasyonlar, ISO ile irtibat halinde olan hükümetler ve STK'lar da bu çabaya dahil oluyor. ISO, Uluslararası Elektroteknik Komisyonu ile yakın işbirliği içinde çalışır. (IEC) elektroteknik standardizasyonla ilgili tüm konularda.

Parça 1 ISO/IEC Direktifi, bu belgeyi geliştirmek için kullanılan prosedürlerin yanı sıra daha ileri bakım için kullanılan prosedürleri de açıklamaktadır.. Particular attention should be paid to the different approval criteria required for different types of ISO documents. Bu belge Bölüm yazım kurallarına uygun olarak hazırlanmıştır. 2 ISO/IEC Direktifi (iso.org/direktiflere bakın).

Lütfen bu belgenin belirli öğelerinin patent haklarına konu olabileceğini unutmayın.. ISO, bu tür patent haklarının herhangi birinin veya tamamının tanımlanmasından sorumlu değildir.. Belgenin geliştirilmesi sırasında belirlenen patent haklarının ayrıntıları profilde ve/veya alınan ISO patent talepleri listesinde yer alacaktır. (iso.org/patents'e bakın).

Bu belgede kullanılan ticari isimler kullanıcılara kolaylık sağlamak amacıyla verilmiştir ve bunların onaylandığı anlamına gelmez.

For an explanation of the meaning of ISO specific terms and expressions related to conformity assessment, and information on ISO’s compliance with WTO principles in Technical Barriers to Trade (TBT), see the following URL: giriiş – Supplementary Information.

Bu belgeden sorumlu komite ISO/TC'dir. 35, Paints and varnishing.

The second edition eliminates and replaces the first edition (ISO 4618:2006), which has been technically revised.

The main changes are listed below.

A) The following terms have been added: Wear, aerosol, appearance, bubble, color retention, dispersion, effect pigment, emulsion, functional pigment, Nano aerosol, nano coating, nano dispersion, nano emulsion, nano incrementant, nano film, nano object, nano pigment, nano scale, nano structure coating, nano suspension, nano texture, non-volatile matter by volume, recoatability, performance, dumpability (from flow change), reflux effect, rheological fixed/rheological behavior, return rust (a synonym for flash rust), rust frost, scratch, streaking, shear-thickening flow behavior/expansion flow behavior, shear thinning flow behavior/pseudoplastic flow behavior, surface structure, suspension, doku, thixotropic/thixotropic behavior, viscoelasticity, viskozite, yield point/yield stress/yield value.

II) The following terms have been amended: Güçlükle tutunmak, aging, caking, aggregation, airless spraying, Antifoaming agent, antifouling coating, application rate, barrier coating, seepage, yapıştırıcılar, fungicides, foaming (instead of foaming), frosting, parlaklık, pulverization, kaplama, kaplama, coating materials, kaplama işlemi, cohesion, renk, coloring materials, consistency/bulk, corrosion, Cracking, crater, crocodile, crow’s feet cracking, defoaming agent, de-nibbing, Vacuum, dirt retention, kurutma, Dayanıklılık, dye, elastic, gravür, incrementant, FEATHER edge, feed, dolgu maddesi, dolgu maddesi, film forming, film forming, alevlenme noktası, Esneklik, floating color, tesviye, tesviye, flow agent, Hardness, covering power, HOLIDAY, Thermal spray, hydrocarbon resin, Impregnating material, tank preservative, lapping, floating, aşınma direnci (changed to abrasion), mask Masking, Isochromatic, Nonvolatile, Boyalar, pigmentler, Polymer Dispersions, Applicable Life, Preparation grade, Recoating, Resin, running, Rust grade, flow-hang, flow-hang, parlak, Shelf life, workshop primer, stopper, synthetic resin, thixomer/thixomer, vernik.

C) The following terms have been deleted: sandblast primer, chromate treatment, latex paint/latex paint, cover-up (as a synonym for cover-up), liquidity (changed to dumping), hair cracking, cover-up (as a synonym for cover-up), high solid content, miss (synonym for holiday).

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

1 Uygulama kapsamı

This INTERNATIONAL standard defines the terms used in the field of coatings (boyalar, boyalar ve vernikler için vernikler ve hammaddeler).

Terms relating to specific applications and properties are dealt with in the standards relating to those applications and properties, Örneğin, anti-corrosion, kaplama tozları.

Nanotechnology terminology is harmonized with ISO/TS 80004-4.

In addition to English and French (two of the three official ISO languages), this International standard gives equivalent terms in German; These are published by member groups in Germany (İTİBAREN). Fakat, only terms and definitions given in the official language are considered ISO terms and definitions.

Not 1: Those terms defined elsewhere in this INTERNATIONAL STANDARD are shown in ITALics.

Not 2 See also ISO Online Browsing Platform (OBP) : iso.org/obp/ui/

2 Terimler ve tanımlar

2.1 Wear and Tear

The process of surface wear or deformation due to friction

2.2 Sand blasting and cleaning

The high kinetic energy flow of the abrasive impinges on the surface to be treated

2.3 Accelerators

An additive that increases the speed of a chemical reaction

2.4 Acid value

Milligrams of potassium hydroxide (KOH) required to neutralize 1 g of sample under specified test conditions

2.5 Akrilik reçine

A synthetic resin produced by polymerization or copolymerization of acrylic and/or methacrylic monomers, usually with other monomers

2.6 Additives

Any substance added in small amounts to a coating material to improve or otherwise alter one or more properties

2.7 Yapışma

Adhesion at the interface between a solid surface and another material caused by molecular forces

Giriş Notu 1: Adhesion should not be confused with cohesion.

2.8 Güçlükle tutunmak

The force required to separate the coating from the substrate or another coating

2.9 Aerosol

A solid or liquid particle dispersed in a gaseous medium

2.10 After the tack

The property of a film to remain viscous after normal drying or curing

2.11 Aging

The change of one or more initial characteristics of a film over time

2.12 Cohesion

A collection of weakly bound particles or aggregates or a mixture of both, in which the resulting surface area is similar to the sum of the surface areas of the individual components

Giriş Notu 1: The force applied to the aggregates/agglomerates during paint production may vary depending on the method used.

2.13 Total

For particles containing strongly bonded or fused particles, the resulting surface area may be significantly less than the sum of the calculated surface areas of the individual components

Giriş Notu 1: The force applied to the aggregates/agglomerates during paint production may vary depending on the method used.

2.14 Airless spraying

The process of applying coating material at high pressure by forcing it through an orifice in the absence of air supply

2.15 Alkyd resin

A synthetic resin formed by condensation of fatty acids (or oils) and carbonic acid with polyols

2.16 Amino resin

A synthetic resin formed by condensation of urea or melamine or its derivatives such as benzyguanidine with formaldehyde

Not 1: These resins are usually etherized with alcohol.

2.17 Anti-adhesion agent

An additive that usually rises to the surface during drying to prevent adhesion

2.18 Antifoaming agent

Additives that prevent foaming or reduce the tendency of a coating to foaming

Giriş Notu 1: See also defoaming agent.

2.19 Antifouling paint

Coating material applied to underwater parts of hull or other underwater structures to prevent biological growth

2.20 Anti-settling agent

Additives that prevent or delay the deposition of pigments and/or incretants during paint storage

2.21 Anti-crusting agent

An additive that prevents or delays crusting caused by oxidation during storage

2.22 Apparent density

Mass to volume ratio of uncompacted powder

Giriş Notu 1: See also packing density and tamping density.

2.23 Visual characteristics of appearance surface

Not 1: This includes color, parlak, image clarity (DOI), pus, surface structure, doku, orange peel, vesaire.

Giriş Notu 2: The word appearance has no special meaning in English in relation to paint, but is included here for the purpose of illustration to non-English speakers.

2.24 Application rate

The amount of paint required to produce a dry film or coating of a given thickness per unit area under specified working conditions

Not 1: Expressed as l/m 2 or kg/m 2.

Giriş notu 2: See also transmission rate.

2.25 Barrier coating material

A coating material used to isolate a coating system from the substrate to which it is applied to prevent chemical or physical interactions, such as preventing exudation or migration from the underlying coating or substrate

Giriş Notu 1: The use of the German term “Isoliermittel”, which is still in use, should be avoided to prevent confusion with thermal and acoustic insulation materials and electrical insulators.

…

2.53 Coating process

Method of applying coating material to substrate

2.54 Coating system

A combination of all coating materials to be applied or already applied to the substrate

Giriş Notu 1: The actual system can be characterized by the number of coatings involved.

Giriş Notu 2: See also coating.

2.55 Cohesion

The force that binds a film or coating into a whole

Giriş Notu 1: Cohesion should not be confused with adhesion.

2.56 Coil coating

The coating process, in which the coating material is continuously applied to the metal coil, can be re-wound after the film has dried

2.57 Cold cracking

Cracks form in the film due to exposure to low temperatures

2.58 Renk

The sensation produced by the human eye in perceiving light of a given spectral component

Giriş Notu 1: It is not recommended to use the German word “Farbe” alone, yani, not to combine words to denote coating materials.

Not 2: Color is characterized by hue, chroma and brightness.

2.59 Color retention

The durability of color

Giriş Notu 1: Color retention can be affected by weathering.

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.60 Coloring materials

Any substance that gives color to other materials

Not 1: Coloring materials include pigments that are insoluble in the application medium and dyes that are soluble in the application medium.

2.61.1 Uyumluluk

< Of material > The ability of two or more materials to be mixed together without causing undesirable effects

2.61.2 Uyumluluk

< Coating material and substrate > The ability of the coating material to be applied to the substrate without causing adverse effects

2.62 Consistency

Flow resistance of coating material subjectively assessed when shear force is applied

2.63 Contrast ratio

The ratio of the reflectance of a coating material applied on a black surface under specified conditions to the reflectance of a coating material of the same thickness applied on a white surface

2.64 Aşınma

Deterioration processes resulting from chemical, electrochemical or microbial reactions caused by exposure to the environment or media

2.65 Cracking

Dry film or coating rupture

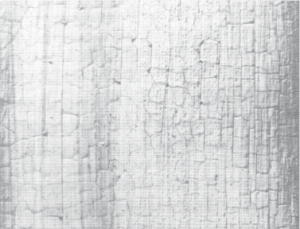

Not 1: The English term “çatlama” is also used for the specific form of cracking shown in Figure 2.

Giriş Notu 2: Crocodile and crow’s feet are examples of cracked forms.

Figür 2 – Cracking

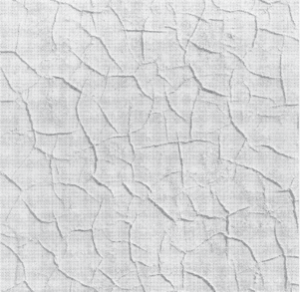

Figür 3 – Cracking

2.69 Critical pigment volume concentration

Polyvinyl chloride

The value of the pigment volume concentration at which the gaps between nominally contacted solid particles are just filled by the adhesive, above which some properties of the film change significantly

2.70 Alligator skin

A crevice pattern characterized by a crevice pattern similar to that of alligator skin

Giriş Notu 1: Figür 4 shows an example of a crocodile.

Figür 4 – Crocodile

2.71 Cracked crow’s feet

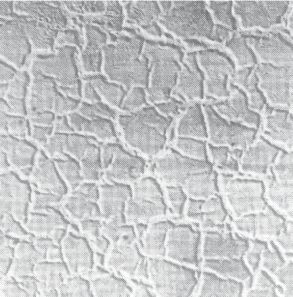

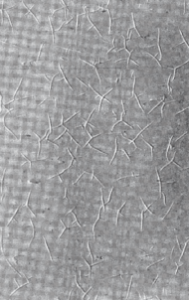

A form of cracking characterized by a pattern of cracks resembling crow’s feet

Giriş Notu 1: An example of crow’s feet cracking is shown in Figure 5.

Figür 5 – Crow’s feet crack

2.72 Bakım

Hardening of

Increase the molecular size of the adhesive by chemical reactions

Giriş Notu 1: Acceleration can be achieved by physical means (sıcaklık, radyasyon) or catalysts.

Not 2: In French, curing is used for two-component coatings, with the second component often referred to as hardener.

2.73 Curing agent

Additives that promote chemical curing of coatings

2.74 Screen painting

Paint is applied by making the item to be painted horizontal through the falling sheet of the continuous recycling paint

2.75 Cut in

Apply the paint to the desired lines

Not 1: An example is applying a coating material to a window frame rather than applying it to the glass.

2.76 Antifoaming agent

Additives that reduce foam that may form during paint manufacturing and/or application

Giriş Notu 1: See also defoaming agent.

2.77 Oil removal

Yağ, gres, and similar substances are removed from the surface with organic solvents or water-based cleaners prior to painting

2.78 Tip removal

Remove small particles that protruded from the dry surface of the applied coating or substrate

2.79 Scale removal

Removes scale oxide or layer rust from steel or other ferrous metal substrates

2.80 Dilution

Volatile liquids, single or mixed, Hangi, although not solvents, may be used with solvents without causing any harmful effects

Giriş Notu 1: See also solvents and thinners.

2.81 Impregnation

Paint is applied by immersing the object to be painted in a bath containing paint and then removing it and allowing it to run dry

2.82 Elektrikli süpürge

The tendency of a dry film or coating to attract large amounts of dirt to a surface

2.83 Fouling retention

Dry films or coatings tend to retain dirt on surfaces that cannot be removed by simple cleaning

2.84 Dispersion

A heterogeneous mixture of at least two materials that are insoluble or only slightly soluble in each other and have no chemical bond

Not 1: Dispersion is a general term for suspension and emulsion.

2.85 Dispersing agent

An additive that promotes the dispersion of solids in the medium and improves the stability of the mixture during manufacturing

2.86 Dryer

Compounds, usually metal soaps, are added to products that are dried by oxidation to speed up the process

2.87 Kurutma

All processes of coating material applied from liquid to solid

Giriş Notu 1: “oxidative drying” is often used instead of the more correct term “oxidative hardening”.

Giriş notu 2: See also curing.

2.88 Dry oil

Oils based on unsaturated fatty acids, which produce thin films by oxidation

2.89 Dayanıklılık

The ability of a coating to resist the destructive effects of its environment

2.90 Dyes

Coloring material, soluble in application medium

2.91 Effect pigment

Pigmentler, usually in the form of plates, confer not only color but also other properties, such as iridescent (thin layer interference), angular dependence of color (color movement, color following, light and dark following) or texture

2.92 Weathering

A phenomenon that occurs when water-soluble salts in a dry film or substrate migrate to the surface and form crystalline deposits

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.93.1 Elasticity

The ability of a dry film to recover after removal of any transverse stress

Giriş Notu 1: See also flexibility.

2.93.2 Elasticity

The material exhibits reversible recovery after deformation

2.94 Elektrodepozisyon

The process of depositing a layer of water-based coating material on an object forming an anode or cathode under the influence of an electric current, depending on the nature of the coating material

2.95 Electron beam curing

The process of rapid curing of specially formulated coatings by concentrated electron flow

2.96 Electrostatic spraying

Method for applying electrostatic potential difference between the article to be painted and the atomized coating particles

2.97 Lotion

A finely dispersed mixture of at least two liquids that are insoluble or only slightly soluble in each other

2.98 Epoxy ester

A synthetic resin formed by the reaction of epoxy resin with fatty acids and/or oils

2.99 Epoxy resin

A synthetic resin containing an epoxy group, usually made from epichlorohydrin and bisphenol

2.100 Etching primer

Primer, usually provided in the form of two reactive components, is mixed immediately prior to construction and is designed to react with metal surfaces to improve adhesion of subsequent coatings

2.101 Etching

Use chemicals to clean, roughen or remove the natural oxide layer from the surface prior to painting to increase adhesion

2.102 Expander

A granular or powdered substance, insoluble in a medium, used to alter or affect certain physical properties

Giriş Notu 1: The terms “Extender”, “Extenderpigment”, “Pigmenttextender” veya “Verschnittmittel” should be avoided in German.

2.103 Oozing

The liquid component of the paint migrates to the surface of the film

2.104 Recession

Color loss of coating film _

2.105 Feather edge

Reduce the thickness of the edge of the coated area before recoating to avoid ridges in the combined layer

2.106 Feeding

The consistency of the paint changes during storage, yani, the viscosity increases, to the point where it becomes unusable

2.107 Paketleme

Coatings with a high proportion of incremental agents are mainly used to eliminate irregularities in the substrate to be painted and improve surface appearance

Giriş Notu 1: The term filler is also widely used for incremental agents.

2.108 Filling

Apply filler to provide a horizontal surface

2.109 Movies

A continuous layer of coating

2.110 Film formation

The transition of the applied paint from liquid to solid or, in the case of powder coatings, from liquid to solid phase

Not 1: Film formation is achieved by drying and/or hardening. Two changes can be made simultaneously.

2.111 Grinding fineness

A term relating to the largest particle size in an abrasive or paint

2.112 Finish paint

The final coating of the coating system

2.113 Fish eye

Craters are present in the coating, each with a small impurity particle in the center

2.114 cilt temizleme

Small parts of the coating fall off due to loss of adhesion

2.115 Flame cleaning

The process of applying a reducing flame to the surface followed by manual or mechanical cleaning operations

2.116 Flame treatment

Even this is made possible by means of flame pretreatment, in which the surface of a plastic material, such as polyethylene, is oxidized to improve the wettability of the coating material and the adhesion of the coating

2.117 Flash closing time

The time required between wet and wet continuous coatings or the time for most of the volatile matter to evaporate before baking or radiation curing

2.118 alevlenme noktası

Test bölümünün minimum sıcaklığı, measured in the specified manner, is corrected to 101.3 kPa atmospheric pressure at which the application of an ignition source will cause the vapor of the test section to ignite instantly and the flame will spread throughout the surface of the liquid under the specified test conditions

2.119 Flash rust

A very thin rust layer is quickly formed on iron substrate after sandblasting, or rust is quickly formed on iron substrate after water based coating is used

2.120 Esneklik

The ability of a dry film or coating to deform without damaging the substrate to which it is applied

Giriş Notu 1: It is incorrect to use the term “elastic” to describe the flexibility of a film.

2.121 Floating

One or more pigments separate from the colored coating material, resulting in streaks or areas of uneven color on the coating surface

2.122 Flocculation

A loosely adhered pigment or additive agglomerate in a paint

2.123 Floods

The movement of pigment particles in the liquid paint produces a color that, although uniform over the entire surface, is significantly different from the color of the wet film that has just been applied

Giriş Notu 1: See “Foliar”.

2.124 Flow

Characteristics of coating materials capable of leveling

Not 1: Flow here is not rheological.

2.125 Flow agent

An additive that improves the leveling of a coating on a substrate

2.126 Flow coating

The coating material is applied by dumping or allowing it to flow over the object to be coated and allowing excess to be discharged

2.127 Liquidity

A combination of all the rheological properties of the coating material

2.128 Forced drying

The process of drying the coating material is accelerated by exposing the coating material to temperatures above ambient temperatures but below those normally used for baking

2.129 Icing sugar

A large number of very fine wrinkles in the form of a frosty pattern

2.130 Functional pigment

Pigmentler, based on their chemical or physical properties, have other functions besides color

Not 1: Additional features can be corrosion resistance, as a barrier pigment, photocatalytic performance, infrared absorption or infrared reflection.

2.131 Deflate

Gas formation during paint storage

2.132 parlaklık

The optical properties of a surface, characterized by its ability to reflect light from its specular surface

Giriş Notu 1: Examples of gloss are highlights, parlak, mercerization, yarı parlak, saten, mat, ve ölü mat.

2.133 Granulation

Imitate the appearance of wood by using the right tools and coating materials

2.134 Steel blasting sand treatment

The process of sandblasting using granular materials such as steel, slag or alumina (corundum)

Giriş Notu 1: For a more complete description of the term “gravel”, ISO'ya bakın 11124-1 veya ISO 11126-1.

2.135 Hardening agent

A component of a multi-package product that is mixed together and chemically reacts to form a film with the desired properties

Giriş Notu 1: See also curing agent.

2.136 Hardness

The ability of a dry film or coating to resist indentation or penetration by a solid object

2.137 Pus

Milky white opalescence in highlights or clear coatings

2.138 Covering power

The ability of a coating to eliminate the color or chromatic aberration of a substrate

Giriş Notu 1: The German expressions “Deckkraft” Ve “Deckfahigkeit” should be avoided.

Giriş Notu 2: Dönem “coverage” is ambiguous because it is used in some contexts to refer to coverability and in others to refer to transmission rate. More precise terms for covering power and spread rate should always be used.

2.140 Thermal spraying

Spraying of coating materials that reduce viscosity by heating

2.141 Hydrocarbon resin

A resin produced by copolymerization of aliphatic and/or aromatic hydrocarbons

2.142 Impregnation material

A low viscosity coating used to treat absorbent substrates to reduce their absorption rate

Giriş Notu 1: See also Sealants.

2.143 Preservative in the tank

Fungicides used to prevent microbial growth during storage of water-based paints or stock solutions

2.144 Induction period

The minimum time interval required between mixing and application of the coating provided in the form of multi-package products

Giriş Notu 1: Not to be confused with the applicable period.

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.145 Intermediate coating

Any coating applied between primer and topcoat

2.146 Isocyanate resin

Synthetic resins containing free or terminated isocyanate groups, based on aromatic, aliphatic or alicyclic isocyanates

2.153 Marbling

Use the right tools and coating materials to mimic the appearance of polished marble

2.155 Extinction agent

A product added to a coating to reduce dry film gloss

2.157 Homochromatic spectrum

The phenomenon perceived when two specimens are illuminated by a light source with the same color but different spectral reflection and transmission curves

2.158 Abrasive material

The proportion of paint components required to obtain a better dispersion

2.159 Scale grinding

The iron oxide layer formed during the hot rolling of steel

2.160 Mottled

Uneven film appearance due to the presence of irregularly shaped, randomly distributed areas of different colors and/or glossiness on the surface

2.161 Mud crack

Irregular cracking network cracks are formed in the film, which occurs due to volume reduction during drying or curing

2.162 multi-piece loading products

Paints provided in two or more separate components shall be mixed in proportions specified by the manufacturer prior to use

2.163 nanometer aerosol

A solid or liquid nanoobject dispersed in a gaseous medium

2.164 nano coating

Dry film thickness in the range of 1 nm to 100 nm coating

2.165 nm dispersion

Nanomaterial A material dispersed in a continuous phase of different composition

Not 1: Nanodispersions include nanosuspension and nanoemulsion.

Giriş Notu 2: Gaseous matrices are excluded (solid and liquid droplets in gases are “aerosols”).

2.166 nano emulsion

Nanodispersions having a liquid matrix and at least one or more liquid nanoobjects

2.167 nm incremental agent

An expander made of nano-objects

2.168 nanometer film

Thin films with thickness ranging from 1 nm to 100 nm

2.169 Nano objects

A material with one, two, or three external dimensions at the nanometer level

Açıklama 1: This is a general term for all discrete objects at the nanoscale.

2.170 Nano pigment

Pigment, made from nano objects

2.171 nanometer scale

Sizes range from approximately 1 nm to 100 nm

2.172 Nanostructured coating

Coatings with nanoscale internal or surface structure

2.173 Nano suspension

A heterogeneous material mixture consisting of liquid and finely dispersed solid nanoobjects

Not 1: Örneğin, a nanosuspension can be applied to a suspension of a nanopigment or a nanoincremental agent (mineral), or a polymer nanosuspension.

2.174 nanometer texture

Regular surface structure patterns at the nanoscale

2.175 Natural resin

Resins of plant or animal origin

2.176 Non-volatile

Mass residue obtained by evaporation under specified conditions

Giriş Notu 1: Instead of the term “non-volatile matter”, different terms such as solid, dry residue, dry matter, solid matter, drying residue are usually used with their respective abbreviations. Dönem “non-volatile substance”, also used in ISO 3251, should be used together with the abbreviation “NV” instead of these terms.

2.177 Non-volatile matter volume

NVV _ Volume percentage residue obtained by evaporation under specified conditions

2.178 Oil absorption value

The amount of refined linseed oil absorbed by the pigment or incrementant sample under specified conditions

Not 1: Oil absorption values can be expressed on a volume/mass basis or on a mass/mass basis.

2.179 Orange peel

The appearance of the film or coating, similar to the texture of the surface of an orange

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.180 Organic sol

Dispersions of thermoplastic polymers, if desired, plasticizers, usually containing pigments, are dispersions in volatile organic liquids

Giriş Notu 1: During heating after application, the organic sol forms an adhesive film through the loss of volatile organic liquid.

2.181 Recoating property

The ability of a film of a coating material to accept coating from different coating materials

2.182 Overlap

A coating of the coating material over and in addition to the previously applied coating

2.183 Overspray

The part of a spray coating that does not reach the surface to be applied

2.184 Painting

A pigmented coating that, when applied to a substrate, forms an opaque dry film with protective, decorative or special technical properties

2.185 Paint remover

A material that, when applied to a coated substrate, softness the coating for easy removal

2.186 Particle size

Linear dimensions of pigments, incrementants, or other particulate matter, such as those present in polymer dispersions

Not 1: Usually expressed as average particle size.

2.187 Peeling

Large area of coating peeling due to loss of adhesion

2.188 Verim

Define the characteristics of product behavior

Not 1: For the product name, special features should be stated.

Giriş Notu 2: The word “performance” has no special meaning in English in relation to paint.

2.189 Permeability

The property of a coating or coating that allows a liquid or gas to diffuse through it

2.190 Fenolik reçine

A synthetic resin formed by condensation of phenol, its homologues and/or derivatives with aldehydes, especially formaldehyde

2.191 Phosphating

Chemical pretreatment of certain metal surfaces using solutions consisting primarily of phosphoric acid and/or phosphates

2.192 Acid washing

Rust and oxide scales are removed from the iron matrix by electrochemical procedures or by acidic solutions usually containing inhibitors

Not 1: In German, dönem “Beizen” also means:

A) the process of treating metal surfaces with chemical agents to improve adhesion before painting;

B) Special treatment of wood coloring, as in the English term “staining”.

2.193 Pigmentler

A coloring agent composed of particles, insoluble in the application medium (Örneğin. paints or plastics)

2.194 Pigment volume concentration PVC

The ratio of the total volume of pigments and/or incrementants and/or other non-film-forming solid particles in the product to the total volume of non-volatile substances, expressed as a percentage

2.195 Pinhole

The presence of small holes in the film or coating, similar to those made with pins

2.196 Plasticizer

A substance added to a coating material to make a dry film more flexible

2.197 Plastic sol

A stable dispersion of a thermoplastic polymer in an organic liquid, most of which are non-volatile plasticizers miscible with the polymer, usually containing pigments

Giriş Notu 1: When heated after application, the polymer and plasticizer melt to form a cohesive film.

2.198 Polyester reçinesi

A synthetic resin formed by condensation of polyacids and polyols

Not 1: Based on their chemical structure, saturated and unsaturated polyester resins are distinguished.

2.199 Polymer dispersion

A liquid or semi-liquid material, usually milky in appearance, containing a polymer material in a steady state, finely dispersed in a continuous liquid phase, usually water (aqueous dispersion) or organic liquid (non-aqueous dispersion, NAD)

2.200 Poliüretan reçine

A synthetic resin formed by the reaction of a multifunctional isocyanate with a compound containing a reactive hydroxyl group

2.201 Applicable period

The maximum time that a coating material provided as a separate component should be used after the components are mixed together

Not 1: THE TERM APPLICABLE PERIOD CAN BE RELATED TO THE MAXIMUM TIME THAT THE COATING WILL MAINTAIN GOOD DRY FILM CHARACTERISTICS AFTER MIXING and/OR THE MAXIMUM TIME THAT THE LIQUID COATING WILL MAINTAIN good application characteristics after mixing.

2.202 Liquidity

The ability of dry powder to flow or pour

2.203 Actual seeding rate

The actual spread rate obtained on the specific substrate to be applied

2.204 Prefabricated primer

A quick-drying primer applied to sandblasting clean steel that protects steel during structural fabrication while still allowing steel to be cut and welded

2.205 Preparatory level

Visual cleanliness of steel surfaces after removal of corrosion products and/or contaminants by the preparation method

2.206 Primer

A paint prepared to be used as a primer on a prepared surface

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.207 Bottom coating

The first coat of the coating system

2.208 Recoating ability

The ability of a coating to accept further coating of the same coating material

2.209 Return effect

The ability of a coated surface to restore its original appearance after damage such as scratches

2.210 Resin

Mainly amorphous macromolecular materials, ranging from solid to liquid

2.211 Reducer

An additive used to slow down a chemical reaction or a change in physical state

2.212 Rheological modifier

Additives used to regulate the flow properties of coatings

Not 1: Examples of rheological modifiers are flow agents, koyulaştırıcılar, and thixotropic agents.

2.213 Rheological behavior

The behavior of a material, where rheological parameters (Örneğin., shear viscosity) increase over time to a constant limit value under a constant mechanical load and, for a given time dependence, return to the initial state after decreasing the load

2.214 Roller application

A coating process in which the coating material is applied through a hand-held roller

2.215 roll coating

A coating process in which a sheet or flat article is passed between two or more horizontally mounted rigid rollers and the coated material is transferred from the rollers to one or both surfaces of the sheet or article

Not 1: This process can be used to apply coating materials to individual items (Örneğin. panels, flat doors) and peel materials.

2.219 Rust resistance grade

Classification of scale oxide and/or rust on steel surfaces before cleaning

2.221 Stream hanging

Downward movement of the coating material during construction and/or drying in vertical or inclined position, resulting in irregular dry coating

2.222 Grinding

The grinding process used to level and/or roughen the substrate

2.225 Sealant

An organic material that provides a flexible, impervious continuous barrier between two adjacent surfaces

2.226 Sealing machine

Coating material, usually uncolored, is applied to an absorbent substrate to reduce absorption and/or consolidate the substrate before painting

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.227 Deposition

Sediment is deposited on the bottom of the paint tank

Not 1: Dense precipitates cannot be re-dispersed by simple agitation.

2.228 Shear thickening flow behavior

Inflation is popular for

When the shear rate or shear stress increases, the material exhibits the behavior of increasing shear viscosity

2.229 Shear thinning flow behavior

Pseudoplastic flow behavior

When the shear rate or shear stress is increased, the shear viscosity of the material decreases

2.230 parlaklık

Gloss was observed at a grazing incidence Angle on an apparently dull surface

Giriş Notu 1: There is no word for “parlak” in German.

2.231 Shelf life

The time that the coated material remains in good condition when stored in its original airtight container under the specified storage conditions

2.232.1 Workshop primer

Protective coating material applied in the workshop to parts subsequently completed on site

Giriş Notu 1: See also Precast primer.

2.232.2 Workshop primer

< Yüzey işleme > A coating material applied directly to the steel substrate after sandblasting

2.233 Shot blasting

The process of sandblasting using small metal balls

Giriş Notu 1: See ISO 11124-1 veya ISO 11126-1 for a more complete description of the term “lens”.

2.234 Silikon reçine

A synthetic resin whose basic structure consists of siloxane (silicon-oxygen-silicon bonds)

2.235 Sinking

The coating material film is partially absorbed by the substrate, which is mainly manifested by local differences in gloss and/or texture

2.236 Skin

The coating surface in the tank forms a skin during storage

2.237 Solvent

A single liquid or a mixture of liquids, volatile under specific drying conditions, in which the adhesive can be dissolved

Giriş Notu 1: See also diluents and thinners.

2.238 Transmission rate

A certain amount of paint can cover the surface area to provide the desired thickness of the dry film

Not 1: Expressed as m 2 /l or m 2 /kilogram.

Giriş notu 2: See also application rate, actual spread rate, and theoretical spread rate.

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.239 Steam cleaning

Surface contaminants are removed by steam jets

2.240 Plug

Special types of fillers used for specific purposes, such as filling holes and cracks

2.241 Storage stability

The time that the coating material stored under the conditions specified by the supplier remains stable

2.242 Baking

Hardening process, which results in crosslinking (increase in molecular size) of adhesives by applying heat at a material specific minimum temperature and for a minimum period of time

2.243 Removable coating

The coating material can be removed by simply separating it from the substrate on which it is intended to provide temporary protection

2.244 Matrix

A surface to be coated or to be coated

2.245 Surface structure

The shape or form of a surface

Not 1: The surface structure depends on the morphology of the coating, the viewing distance and the focus of the surface image. The surface structure will be affected by the flow of liquid paint and substrate.

2.258 Thickening agent

Additives that increase the consistency of liquid coatings

2.260 Thixotropic agent

Additives used to impart thixotropic fluidity to coatings

2.261 Thixotropy

Thixotropic behavior

The behavior of a material, where rheological parameters (such as shear viscosity) decrease over time to a constant limit under constant mechanical load; Return to the initial state after reducing the load for a given time dependence

2.263 Ink

Dispersions of pigments, with or without incrementants and binders, compatible with paint and used to modify color

2.264 Unsaturated polyester resin

Polyester resins are characterized by carbon-carbon double bonds in the polymer chain that facilitate subsequent cross-linking with reactive solvents, particularly styrene

2.265 UV curing

Hardened coating materials by exposure to UV radiation

2.266 Boyamak

Transparent coating material

Giriş Notu 1: There is no German term for “varnished”.

2.267 Vinyl resin

A synthetic resin formed by polymerization or copolymerization of monomers containing vinyl groups

2.268 Viscoelasticity

A material property that exhibits both elastic and viscous behavior

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.269 Viscosity

A parameter describing the resistance to flow inside a material

2.270 Volatile organic compounds Any organic liquid and/or solid that spontaneously evaporates at the prevailing temperature and pressure of the atmosphere with which it is in contact

Not 1: For the term VOC currently used in the paint field, see volatile organic compound content (VOC içeriği).

Giriş Notu 2: ABD altında. hükümet mevzuatı, VOC terimi atmosferde fotokimyasal olarak aktif olan bileşiklerle sınırlıdır (see ASTM D 3960). Any other compounds are then defined as exempt compounds.

2.271 Volatile organic matter content

Content of VOC

Uçucu organik bileşikler

The quality of volatile organic compounds present in the paint measured under the specified conditions

Not 1: Dikkate alınacak bileşiklerin doğası ve sayısı, kaplama malzemesinin uygulama alanına bağlı olacaktır.. Her uygulama alanı için, limit values and determination or calculation methods are specified by regulations or agreements.

2.272 Wash resistance

Dust, dirt, and surface stains can be easily removed by cleaning dry films without compromising their specific properties

2.273 Wash the primer

A special form of etching primer containing a balanced proportion of inhibitory pigment, phosphoric acid, and a dissolved synthetic resin, usually poly (vinyl butyral)

2.274 Water-based paint

Paints in which the main volatile substance is water

Giriş Notu 2: Dönem “water-based paint” has been deprecated.

2.275 Hydrophobic agent

An additive that imparts waterproof properties to dry films by increasing the interfacial tension between dry films and incident moisture

Not 1: There are also products with hydrophobic characteristics for the treatment of substrates.

ISO 4618-2014 Boyalar ve vernikler için Terimler ve Tanımlar

2.276 Water-soluble coating

Paint with a water-soluble adhesive

2.279 Wetting agent

Additives used to improve the contact between the medium and the pigment/filler particles or between the paint and the substrate, usually by reducing the surface tension

2.285 Zinc-rich paint

Zinc rich primer

Anticorrosive coating material containing zinc powder sufficient to provide an initial cathodic protection concentration

Yalnızca standart bilgi bileşeni kamuya açıktır. İçeriğin tamamını görmek için, standartları resmi kanallardan satın almanız gerekecek.